Paper label suction and conveying mechanism

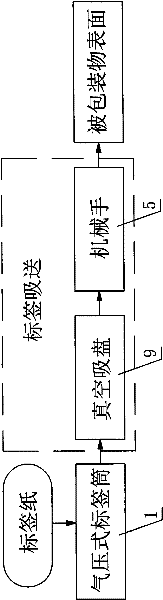

A paper label and label technology, applied in the field of automatic packaging, can solve the problem of inability to meet the automation of packaging machinery and equipment, large-scale production, inability to ensure the accuracy and consistency of label paper placement, and increase the difficulty of the next outer film packaging process. problems, to save labor costs, ensure continuity and consistency, and improve overall uniformity and aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

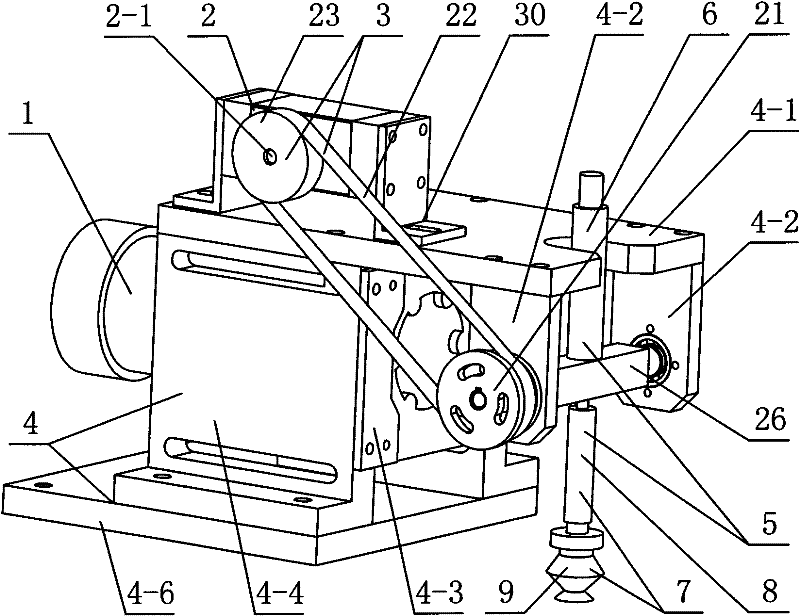

[0029] Such as Figure 3 to Figure 8 As shown, a paper label suction and delivery mechanism includes a pneumatic label cylinder 1, a swing cylinder 2, a synchronous belt transmission device 3, a support 4, a manipulator 5 and a rotating shaft 26, and also includes an assembly connected to an air source 41. The air valve 42 also includes a precision pressure reducing valve 43, a vacuum generator 44, an electromagnetic valve 45 and an electromagnetic valve 46, wherein:

[0030] a) The support 4 includes a cantilever support plate 4-1, a small support plate 4-2, a limit plate 4-3, a left support plate 4-4, a right support plate 4-5 and a bottom plate 4- 6. The left support plate 4-4 and the right support plate 4-5 are fixedly arranged on the bottom plate 4-6, and the cantilever support plate 4-1 is fixedly arranged on the left support plate 4-4 and the right support plate by screws 31 On 4-5, the limit plate 4-3 is fixedly arranged on the front ends of the left side support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com