Mining anti-explosion trackless rubber tire vehicle chassis

A trackless rubber-tired vehicle, mining explosion-proof technology, applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of insufficient use of road adhesion traction, difficulty in adapting to uneven road surfaces, poor vehicle smoothness, etc., and achieve anti-distortion. Strong ability, increase the ground adhesion, avoid the effect of impact bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

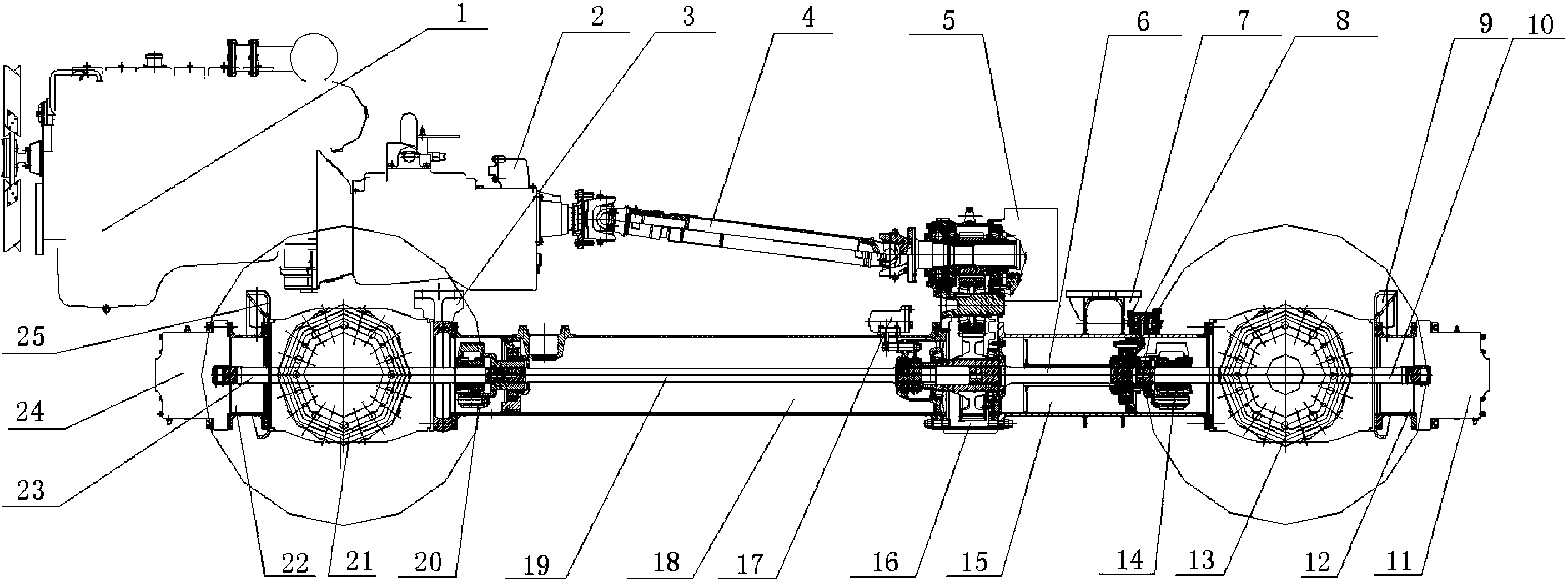

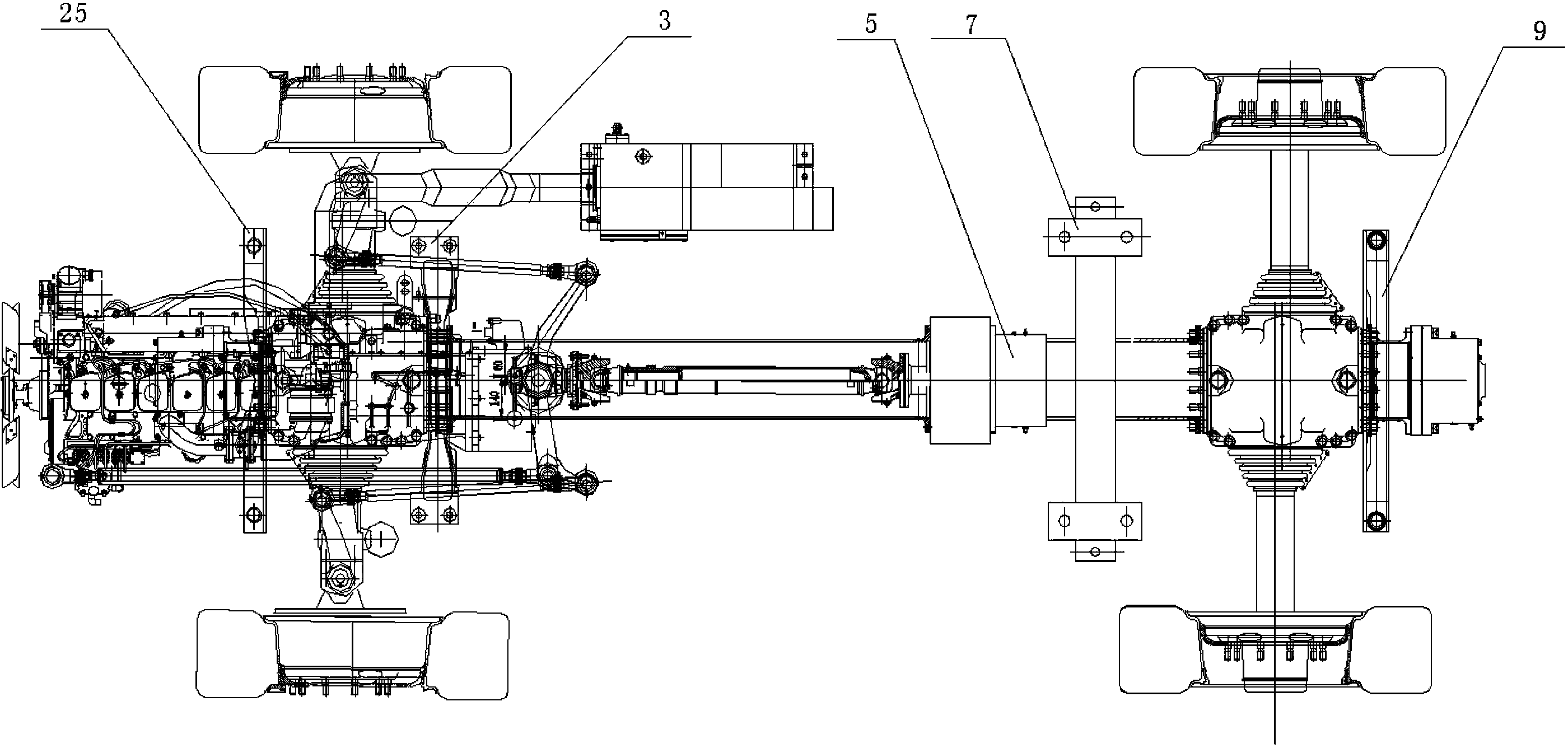

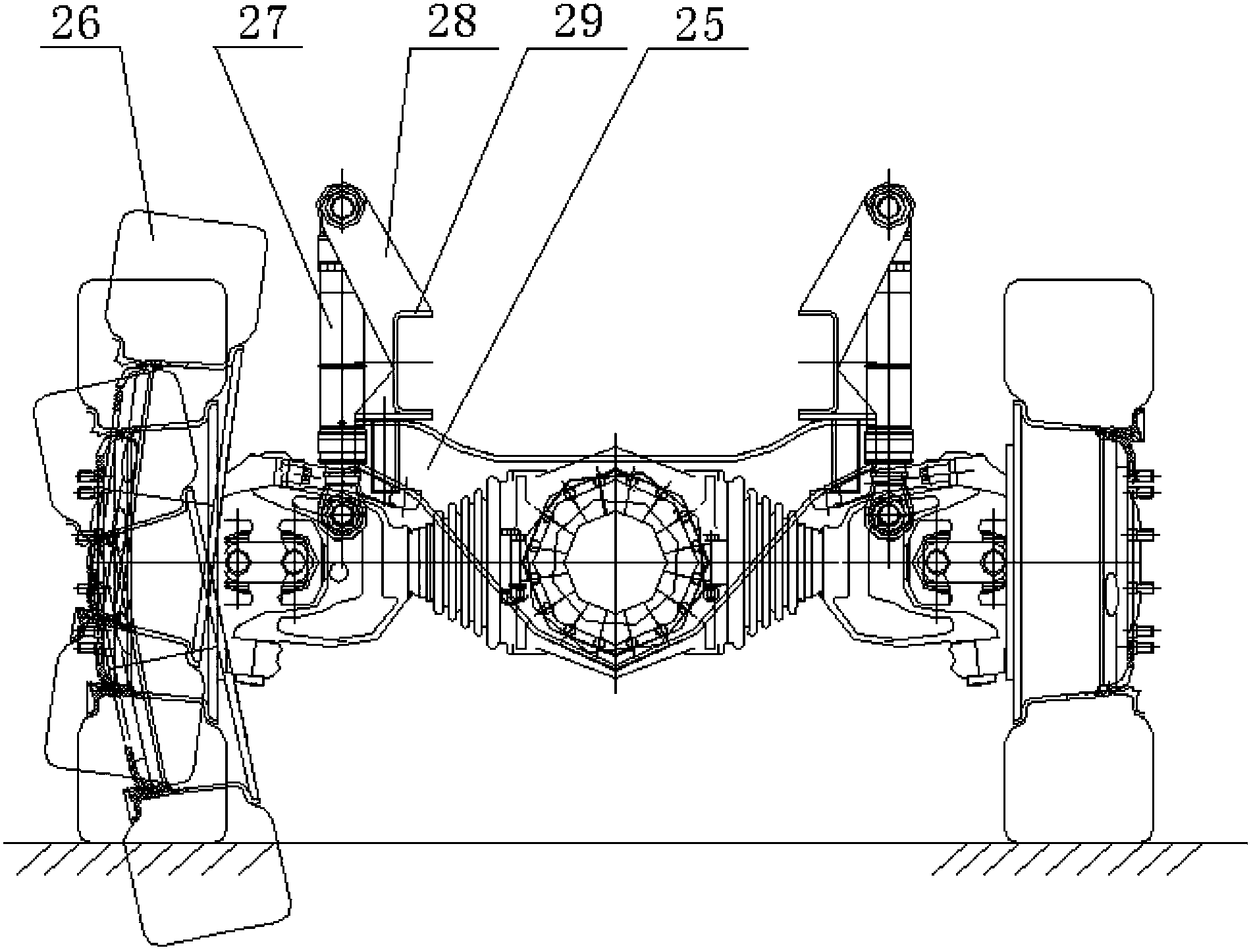

[0018] Such as figure 1 and figure 2 As shown, a mining explosion-proof trackless rubber-tyred vehicle chassis includes an explosion-proof engine 1 located above the front axle 21, a gearbox 2 connected to the explosion-proof engine 1 through a main drive shaft 4, and is located between the front axle 21 and the rear axle 13. The transfer case 16 at the middle rear part, the rear axle planetary gear differential 14 installed on the front end of the rear axle 13, the rear axle 13, the rear service brake 11 connected with the rear end of the rear axle through the rear brake shaft 10, installed on the front The front axle planetary gear differential 20 at the axle rear end, the front axle 21, and the front service brake 24 connected to the front end of the front axle through the front brake shaft 23; the upper rear end of the transfer case 16 is connected with the parking brake 5; The rear output end of the lower part of the transfer case 16 is connected to the rear axle planet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com