Horizontal type pay-off and take-up tension control mechanism

A tension control mechanism, a technology for taking up and paying off the wire, which is applied to manufacturing tools, work accessories, stone processing equipment, etc., can solve the problems of unreasonable structure of the wire passing wheel, no detection means for wire breakage, and high probability of wire breakage, so as to simplify the space. The effect of layout, improving flexibility, reducing the chance of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

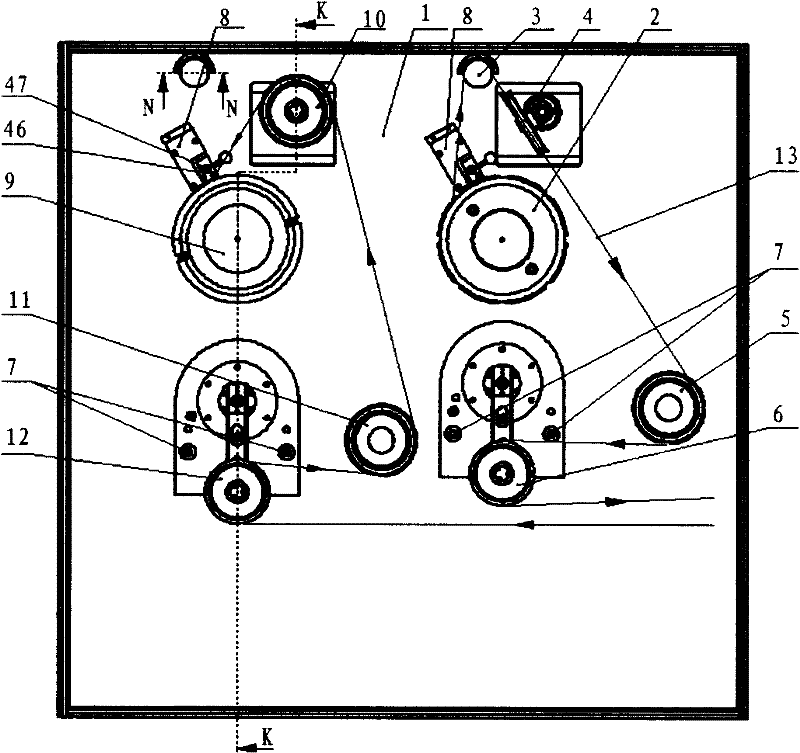

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0023] see figure 1 As shown, a horizontal take-up and pay-off wire tension control mechanism includes a base plate 1 and a steel wire 13. The wire tension measuring guide wheel 5, the pay-off and arranging wire control guide wheel 6 control the tension on the pay-off side; The wire arranging guide wheel 10 and the take-up roller 9 control the tension of the take-up side; the limit post 7 is fixedly connected to both sides of the tension control guide wheel 12 and the wire-releasing control guide 6; the anti-rotation block 8 is fixedly connected to the On the base plate 1, it is located at the upper left of the pay-off roller 2 and the take-up roller 9.

[0024] Further, see figure 2 As shown, the take-up roller 9 is supported on the shaft 27 by the cone heads 14 at two places on the left and right, and is axially positioned by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com