Zipper wire conveying mechanism and zipper tooth planting machine using same

A conveying mechanism and zipper technology, applied in applications, clothing, fasteners, etc., can solve problems such as inaccurate thickness of chain teeth, and achieve the effect of accurate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

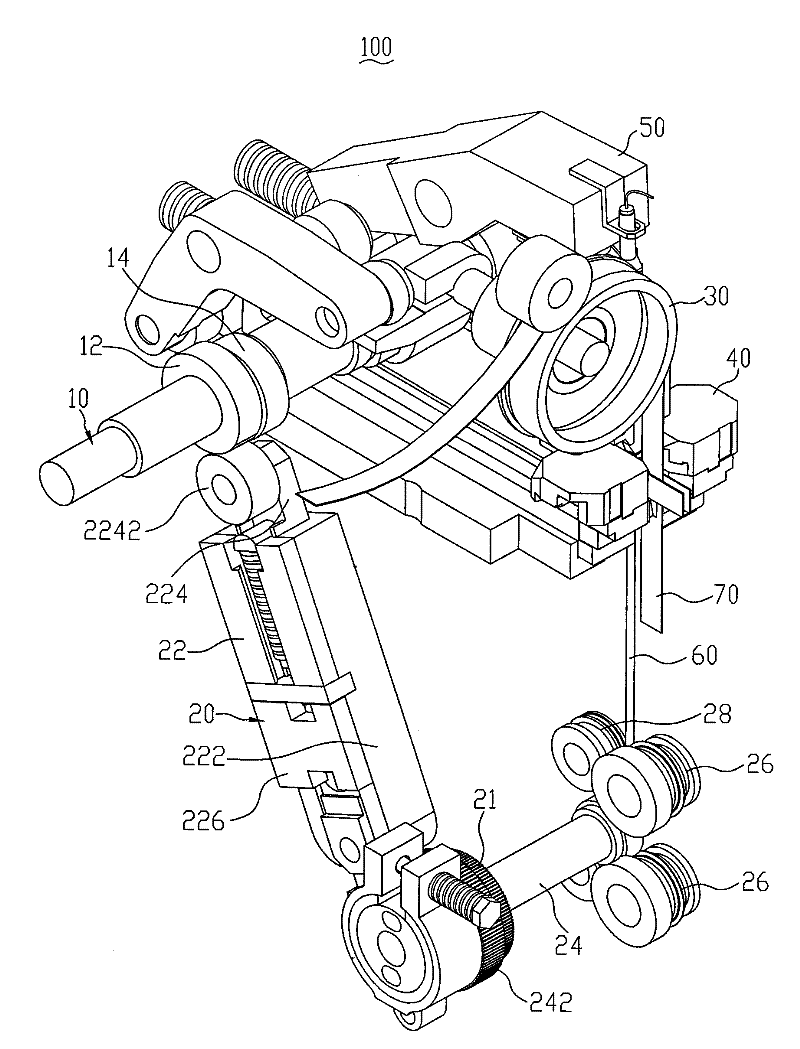

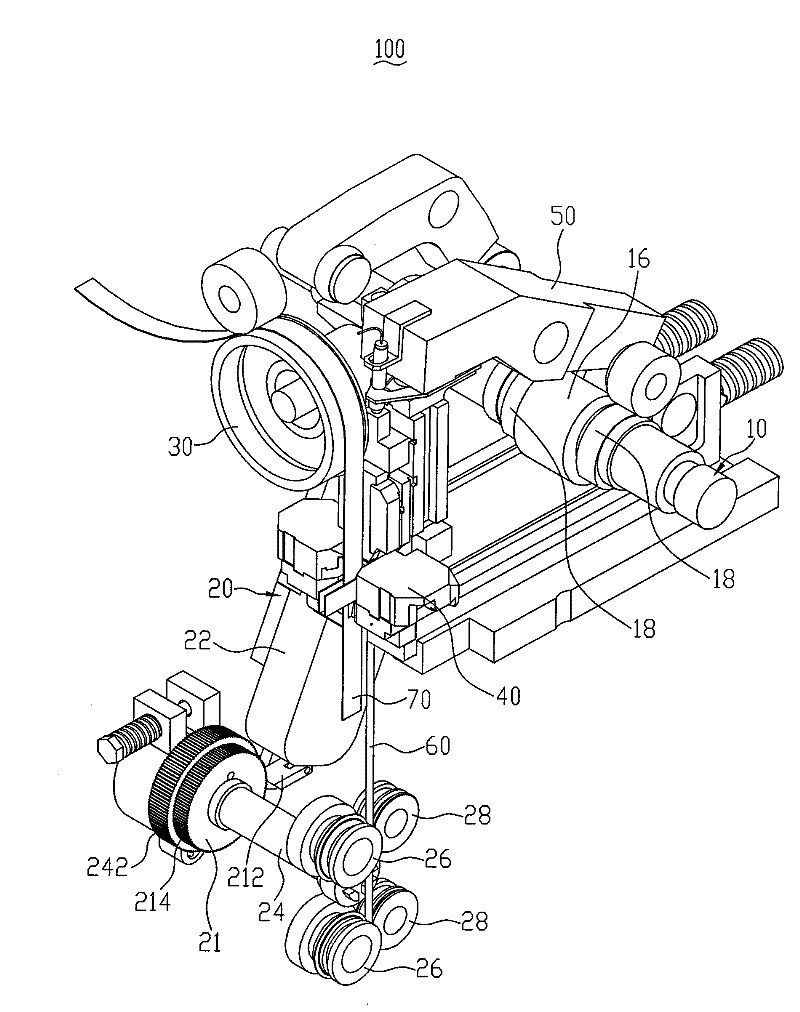

[0037] Please refer to figure 1 , the zipper tooth implanting machine 100 is used to cut a metal wire 60 with a Y-shaped cross-section into several sheet-shaped fastener element blanks, and then punch these fastener element blanks and then implant them on a cloth belt 70, Thereby forming a zipper tooth chain. The zipper tooth implant machine 100 includes a main shaft 10 , a zipper wire conveying mechanism 20 , a traction mechanism 30 , a cutting tooth implant mechanism 40 and a punch mechanism 50 sequentially arranged on a frame (not shown). The zipper wire conveying mechanism 20 is used to intermittently convey the metal wire 60 upwards with an equal distance; the traction mechanism 30 is used to lift the cloth belt 70 upwards intermittently with an equal distance; the cutting tooth implant mechanism 40 is used to place the The metal wire 60 is cut into sheet-shaped chain element blanks; the punch mechanism 50 is used to punch the chain element blanks, forming a mountain-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com