Universal machine core of rolling mill

A universal rolling mill and core technology, which is applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc., can solve the problems of poor reliability of roll group support, difficult to use effectively, and easy to cause safety accidents. , to achieve the effect of being conducive to popularization and use, improving reliability and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

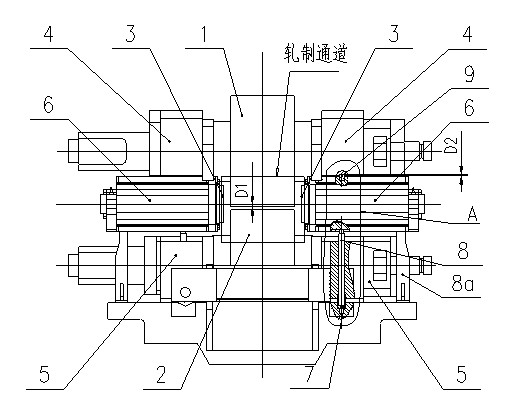

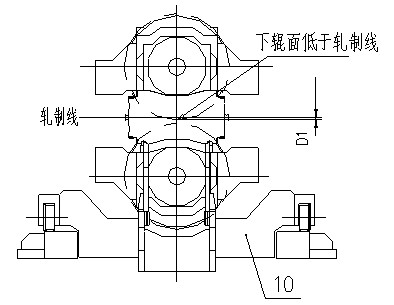

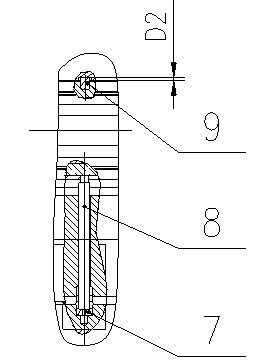

[0024] Such as Figure 1 to Figure 6 As shown, the core of a universal rolling mill includes an upper horizontal roll 1, a lower horizontal roll 2 and a pair of vertical rolls 3 that together form a rolling channel. The two ends of the upper horizontal roll 1 rotate with two upper bearing housings 4 respectively. Cooperate, the two ends of the lower horizontal roll 2 rotate with the two lower bearing housings 5 respectively, and a pair of vertical rolls 3 rotate with the two vertical roll bearing housings 6 respectively. Move out the archway of the rack for roll changing operation. The rolling mill core also includes a quick roll changing device. The quick roll changing device includes a total of four lower horizontal roll positioning rods 7 and four vertical rolls distributed on the left and right sides of the rolling channel. Positioning rods 8, four upper horizontal roll positioning rods 9 and roll changing trolley 10, two positioning rods for lower horizontal rolls and t...

Embodiment 2

[0033] Such as Figure 7 As shown, the rolling mill core includes an upper horizontal roll 1 and a lower horizontal roll 2, the two ends of the upper horizontal roll 1 are respectively in rotation with the two upper bearing housings 4, and the two ends of the lower horizontal roll 2 are respectively connected with the two lower The bearing seat 5 is rotated and matched, and the movement also includes a quick roll changing device, which includes a total of four lower horizontal roller positioning rods 7, four upper horizontal roller positioning rods 9 and a changing roller located on the left and right sides of the roll gap. Roll trolley 10, two lower horizontal roll positioning rods and two upper horizontal roll positioning rods on each side of the roll gap, respectively distributed in front and back of the lower horizontal roll; The lowest position is supported by the positioning rod 9 of the upper horizontal roll, so that the lower roll surface of the upper horizontal roll i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com