Device for rotating turntable

a technology of rotating turntables and turntables, which is applied in the direction of anchoring arrangements, waterborne vessels, vessel construction, etc., can solve the problems of substantial wear, too large boggy systems, and less loaded turret bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

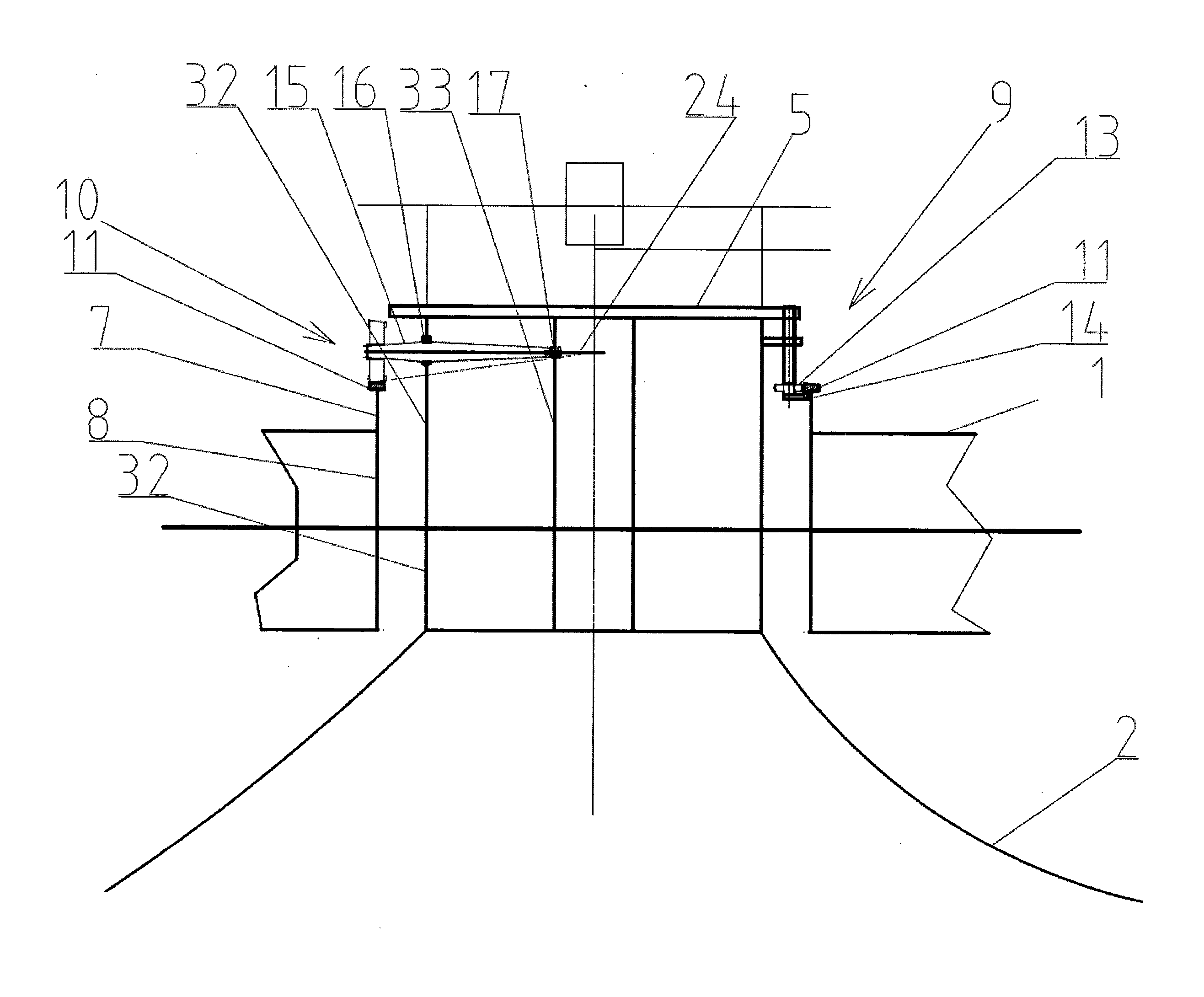

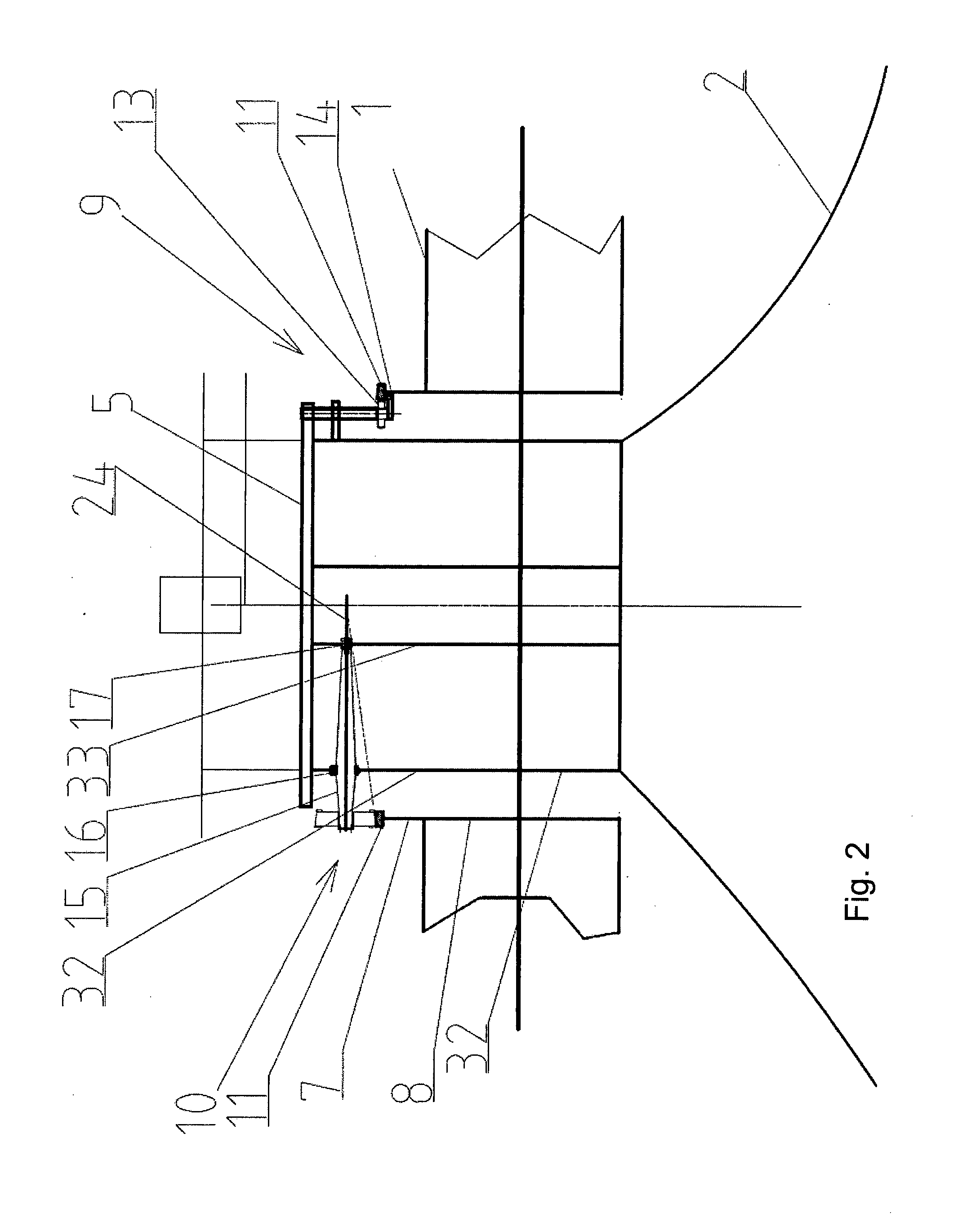

[0023]The turret mounted in the vessel shown in FIG. 1 is mounted into a through-going hole / well 8 in the vessel 1. Mooring lines 2 are suspended in the lower portion of the turret, and used for mooring the vessel to the sea floor 3. Risers and cables may also be suspended from the turret to the sea floor or to a structure or a floating unit in its vicinity. A turret bearing system 6 is mounted onto a bearing support structure 7.

[0024]A swivel coupling 31 is used for bridging the conduits and cables across to the vessel.

[0025]The vessel may be a large ship or a smaller loading buoy being used for transferring products to or from a vessel moored to the anchored vessel 1.

[0026]The bearing system may also be used for turntable simply carrying the weights of the piping and equipment required for the transfer of the products to the vessel.

[0027]A further application may be for supporting large drums onto a rail system on the ground. In general, there is no limit to the application of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com