Reverse-osmosis flow timing automatic mechanical flushing valve device

A technology of automatic machinery and flushing valves, applied in reverse osmosis, osmosis/dialysis water/sewage treatment, semi-permeable membrane separation, etc., can solve troublesome and troublesome problems, cannot meet market diversification, increase the cost of electric shock hazards, etc., and achieve The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

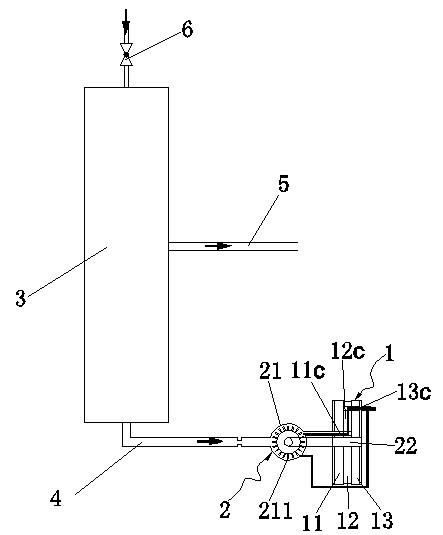

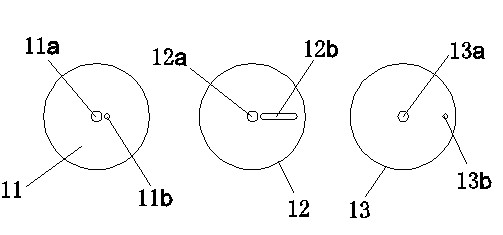

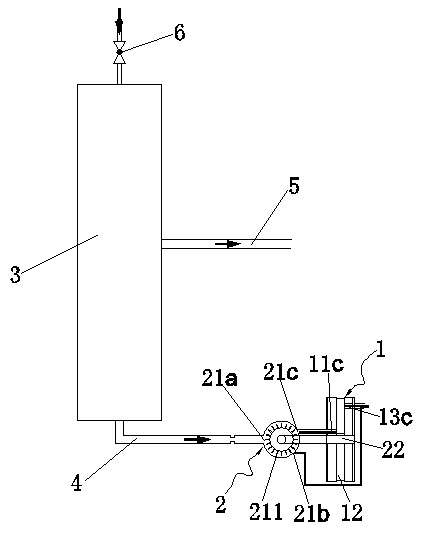

[0020] Figures 1 to 4 Shown is the structural representation of the present invention.

[0021] The reference signs are: mechanical flushing valve 1, first fixed diaphragm 11, first diaphragm shaft hole 11a, first axial through hole 11b, axial flushing water guide hole 11c, movable diaphragm 12, movable diaphragm Shaft hole 12a, radial strip hole 12b, intermediate connecting channel 12c, second fixed diaphragm 13, second diaphragm shaft hole 13a, second axial through hole 13b, axial flushing water channel 13c, energy conversion drive Mechanism 2, energy converter 21, water inlet 21a, first water outlet 21b, second water outlet 21c, impeller 211, conversion output shaft 22, reverse osmosis membrane filter element 3, drain pipe 4, water purification pipe 5, water inlet valve 6.

[0022] like Figure 1 to Figure 4 As shown, a reverse osmosis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com