Mixed plant protein fish feed as well as preparation method and application thereof

A technology of mixing plants and fish feeds, applied in animal feeds, animal feeds, applications, etc., can solve the problems of single enzyme system, slow fermentation speed, amino acid imbalance between rapeseed meal and cotton meal, etc., and achieve strong anti-bacterial ability, High fermentation efficiency and high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

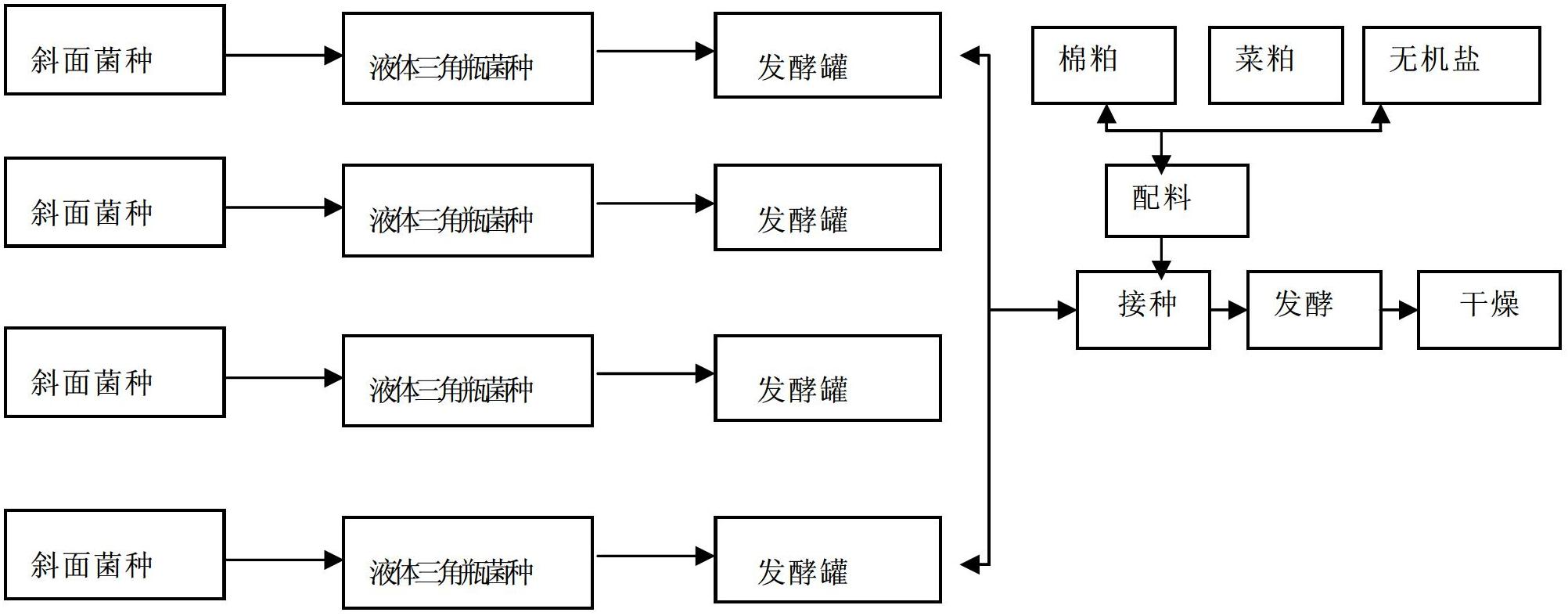

Method used

Image

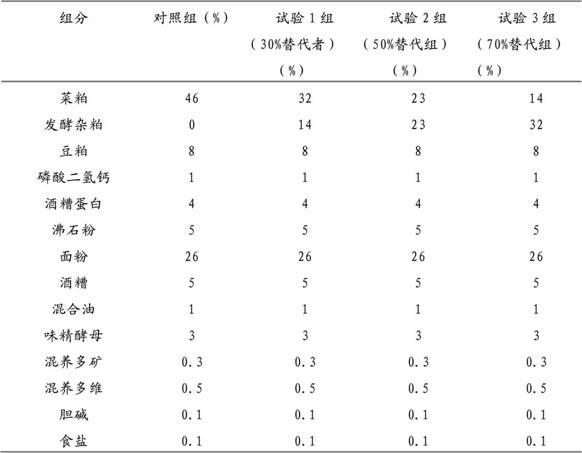

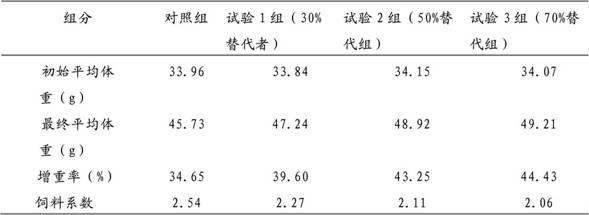

Examples

Embodiment 1

[0032] Preparation of Preliminary Example 1 Bacillus subtilis Fermented Liquid

[0033] 1. Seed cultivation

[0034] After activating the Bacillus subtilis strain, carry out shake flask seed culture;

[0035] The composition of shake flask seed culture medium (by mass percentage):

[0036] 20% potato + 2% sucrose PDA medium;

[0037] Culture conditions: 150r / min, 37°C shaker culture for 18 hours.

[0038] 2. Secondary liquid expansion culture

[0039] Liquid fermentation medium: 3% corn flour, 2% amino acid powder, 0.5% potassium dihydrogen phosphate, 1% calcium chloride, 1% sucrose; sterilize the above liquid medium fermentation tank in place;

[0040] Liquid expansion culture conditions: fermentation temperature is 37°C, the oxygen flow rate can be 100-300L / h, initial pH: 7.0-7.5; speed: 150-200r / min; tank pressure: 0.6-0.8Mpa, fermentation culture 24 Hours, the general effective number of viable bacteria up to 10 9 CFU / ML is enough.

[0041] 3. Liquid fermentation cu...

Embodiment 2

[0044] Preparation of Preparatory Example 2 Enterococcus faecalis Fermented Liquid

[0045] 1. Seed cultivation

[0046] After activating Enterococcus faecalis strains, carry out shake flask seed culture;

[0047] The composition of shake flask seed culture medium (by mass percentage):

[0048] Medium composition: glucose 2%, peptone 1%, yeast extract 0.5%;

[0049] Culture conditions: 150r / min, 32°C shaker culture for 18 hours.

[0050] 2. Secondary liquid expansion culture

[0051] Liquid fermentation medium: 3% soybean meal powder, 3% amino acid powder, 0.5% dipotassium hydrogen phosphate, 2% calcium oxide; sterilize the above liquid medium fermentation tank in place;

[0052] Liquid expansion culture conditions: fermentation temperature is 32°C, its oxygen flow can be 50-100L / h, initial pH: 7.5-8.0; speed: 150-200r / min; tank pressure: 0.1-0.3Mpa, fermentation culture 24 Hours, the general effective number of viable bacteria up to 10 9 CFU / ML is enough.

[0053] 3. L...

Embodiment 3

[0056] Preparation of Preliminary Example 3 Aspergillus Niger Fermented Liquid

[0057] 1. Seed cultivation

[0058] After activating the Aspergillus niger strain, carry out shake flask seed culture;

[0059] The composition of shake flask seed culture medium (by mass percentage):

[0060] 20% potato + 2% sucrose PDA medium;

[0061] Culture conditions: 150r / min, shaker at 28°C for 18 hours.

[0062] 2. Secondary liquid expansion culture

[0063] Liquid fermentation medium: 10% potato, 0.5% diammonium citrate, 0.2% magnesium chloride, 2% sucrose; in-situ sterilization in the above-mentioned liquid medium fermenter;

[0064] Secondary liquid expansion conditions: the fermentation temperature is 28°C, the oxygen flow rate can be 100-300L / h,

[0065] Initial pH: 7.0-7.5; rotating speed: 150-200r / min; tank pressure: 0.6-0.8Mpa, ferment and cultivate for 36 hours, and the spore concentration generally reaches 10 6 more than one / ml.

[0066] 3. Liquid fermentation culture:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com