Screw joint for steel pipe

A technology for threaded joints and steel pipes, which is applied in threaded connections, pipes/pipe joints/fittings, drill pipes, etc., can solve problems such as prone to sticking, and achieve the effect of excellent sticking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

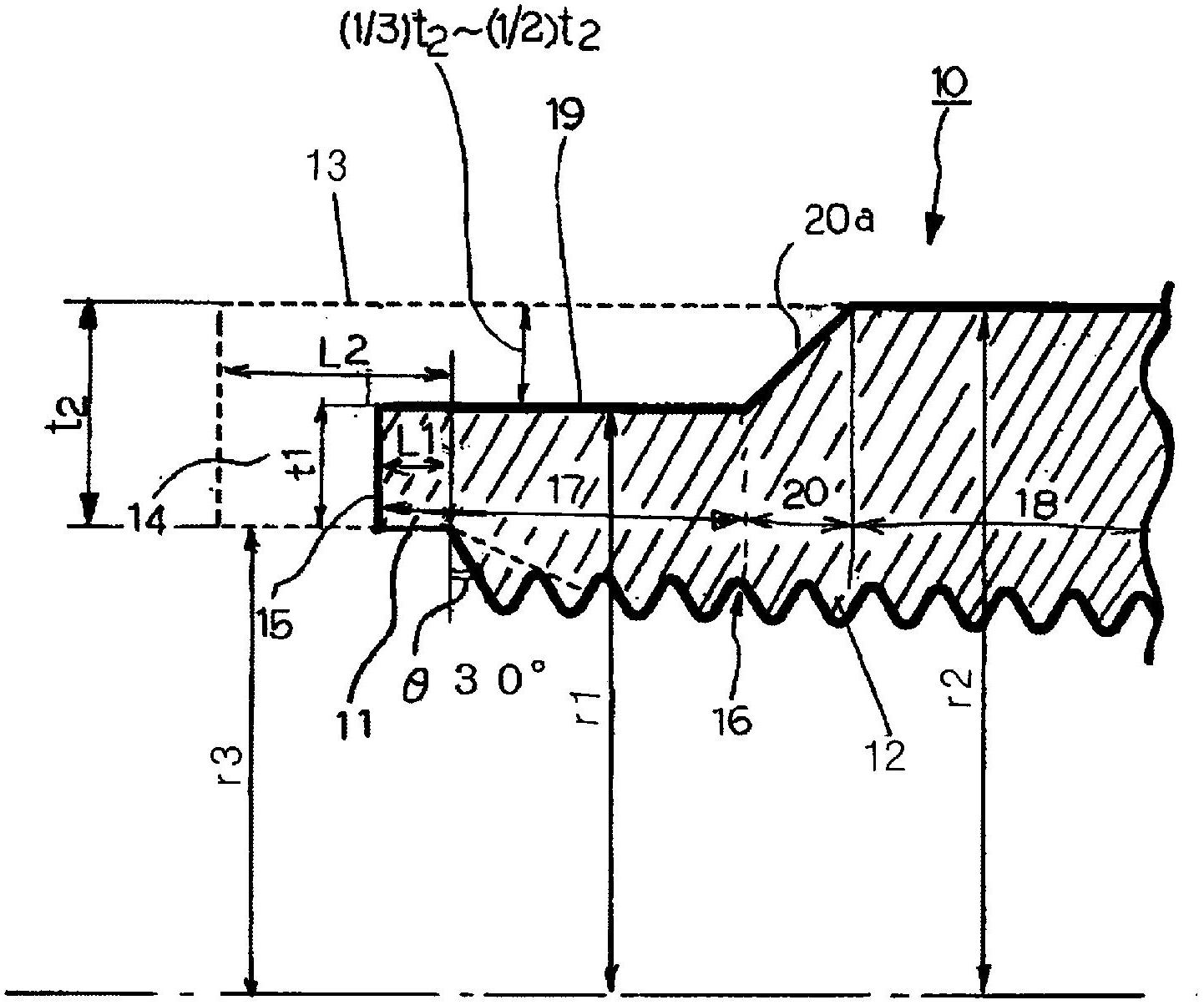

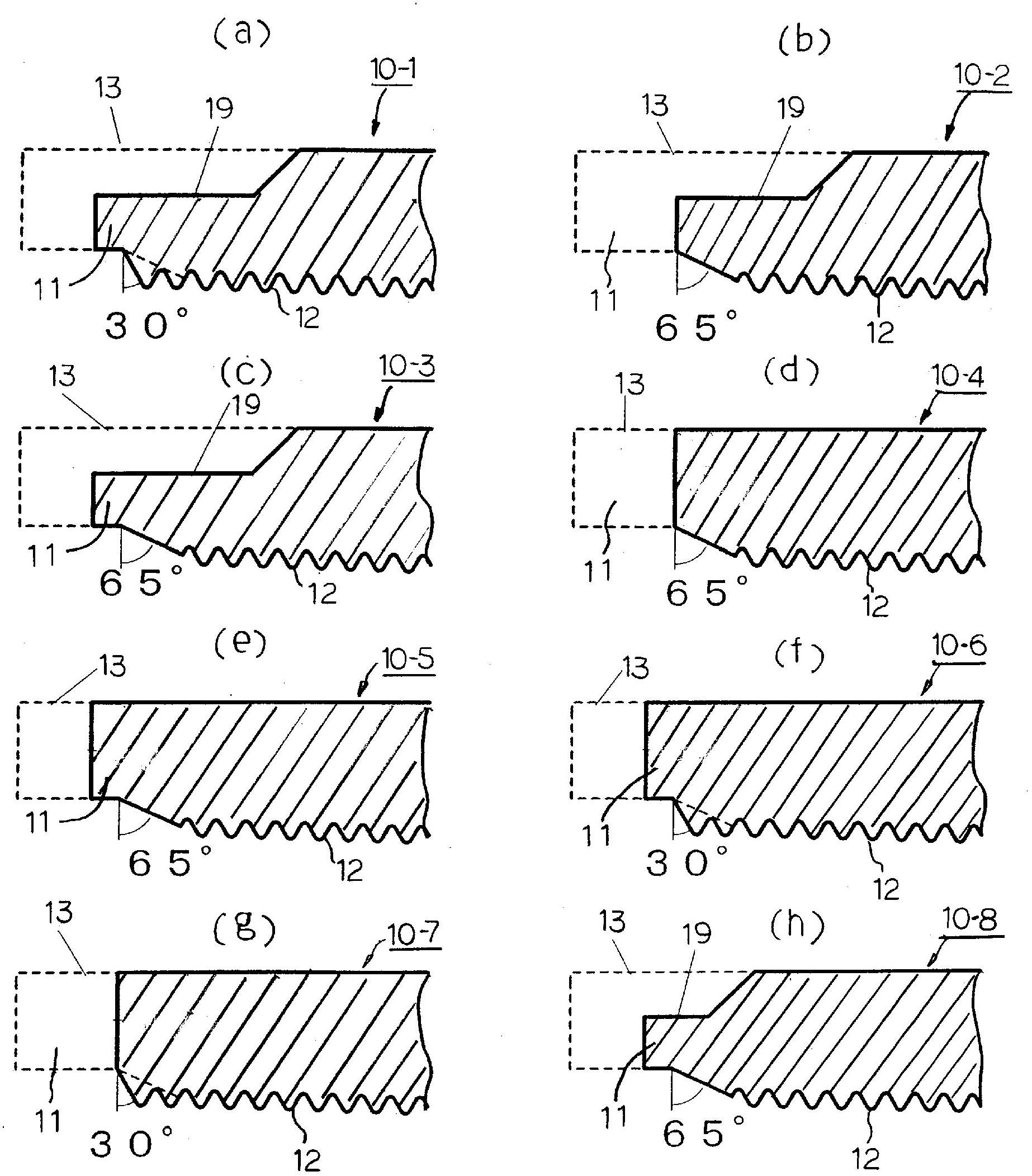

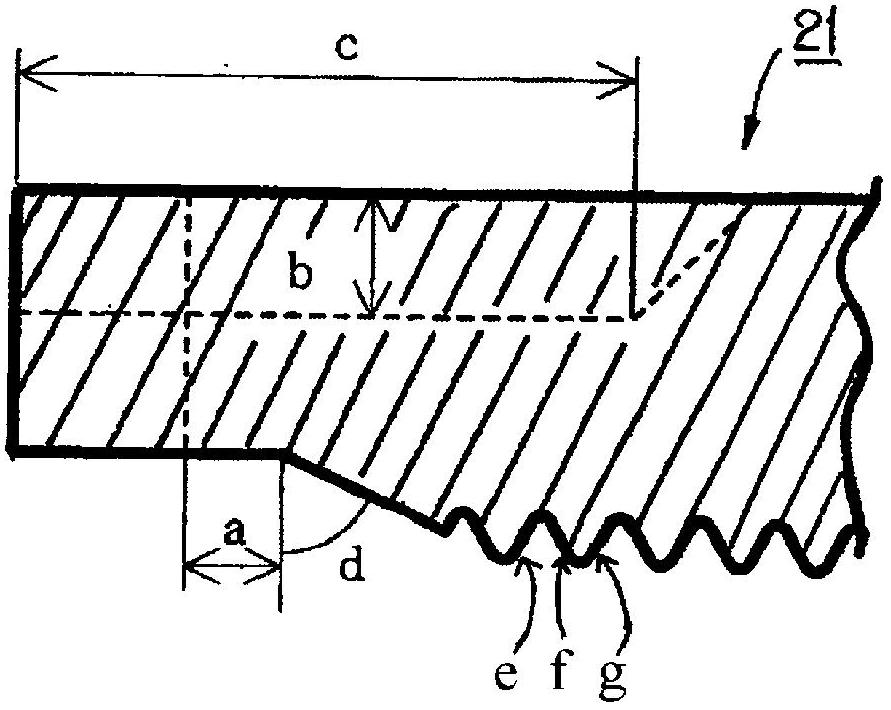

[0084] The following examples are examples for illustrating the present invention and are not intended to limit the present invention. In order to verify the effect of the present invention, the local contact pressure of the threaded thread at the end of the box constituting the threaded joint for steel pipes was evaluated by numerical simulation using the finite element method.

[0085] The threaded joints for steel pipes used in the test are API round threaded joints in the coupling mode for oil well pipes of API specifications 9-5 / 8 inches 47#N80. Simulation analysis was carried out for two states: the state where the threaded joint is tightened to the predetermined fastening position (Vanish Point) and the state where two additional screws are screwed in from the predetermined fastening position.

[0086] Representative specifications of the pipe main body constituting the pin and the coupling main body constituting the box are shown below.

[0087] Tube body

[0088] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com