Milk volume meter, milk volume measuring method, and milking device

A milk volume and flow technology, applied in milking devices, dairy products, applications, etc., can solve problems such as difficult measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, best embodiments of the present invention will be listed and described in detail based on the drawings.

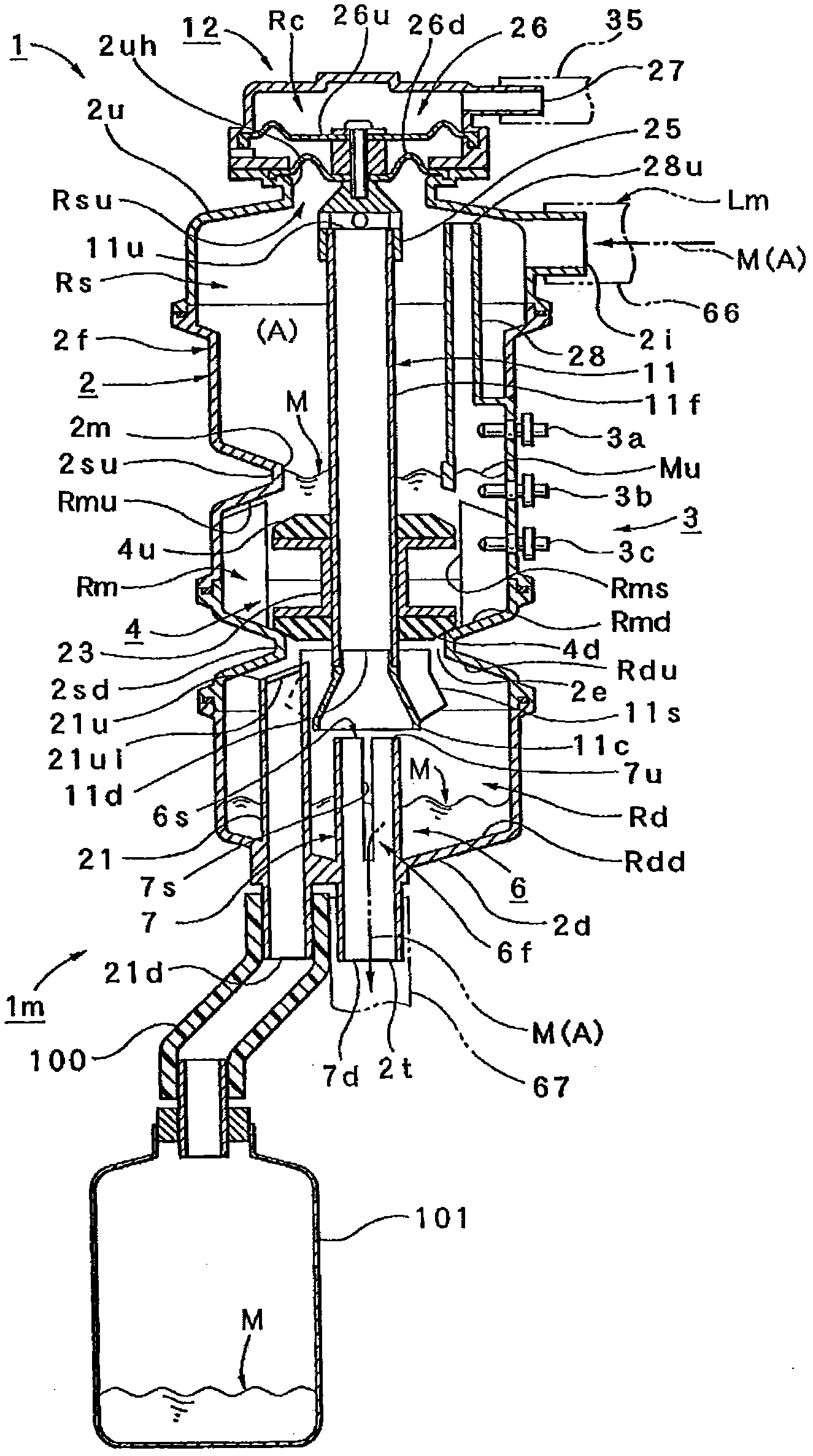

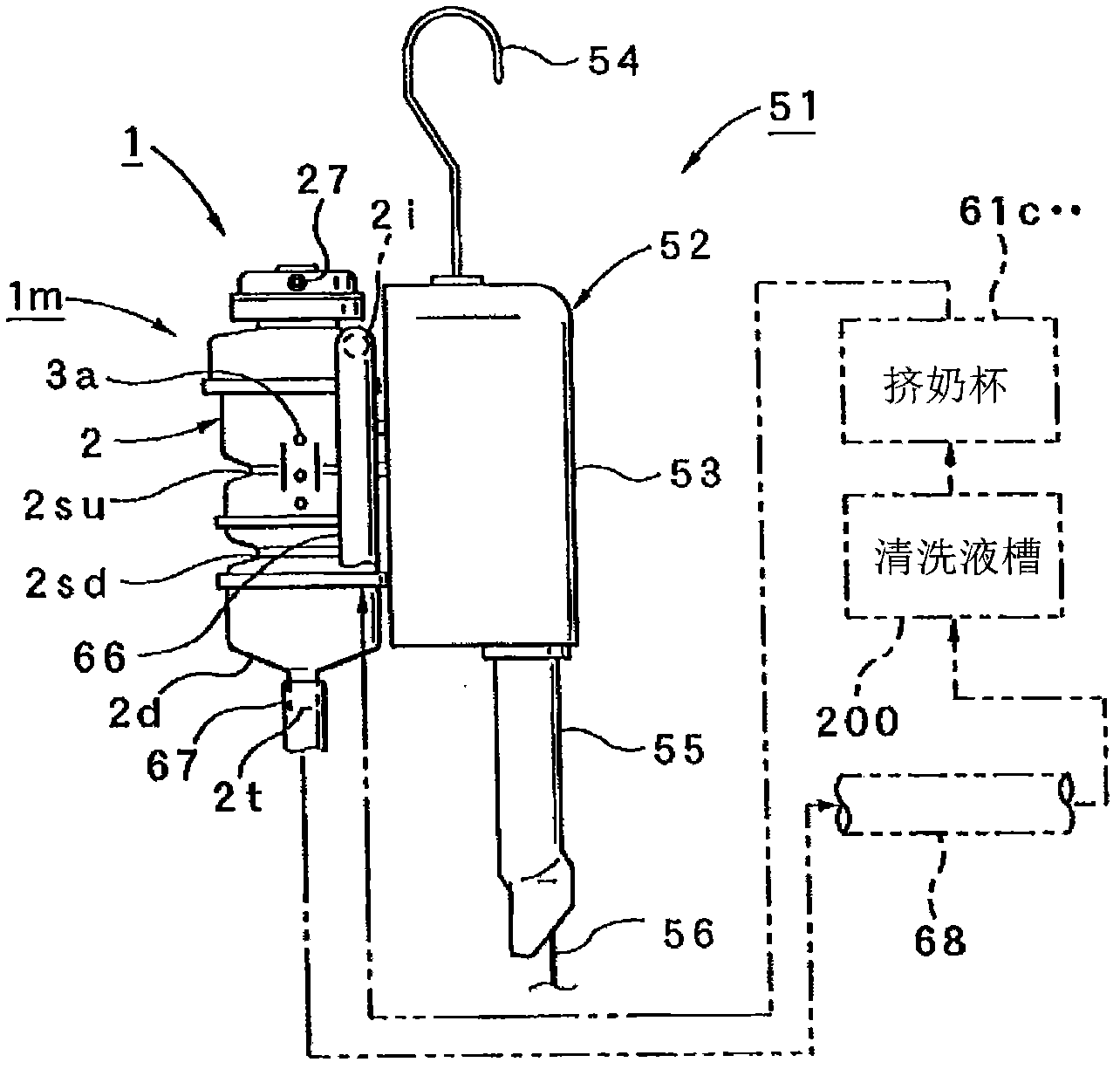

[0049] First, refer to Figure 1 to Figure 5 as well as Figure 9 The structure of the milk meter 1 which concerns on this embodiment is demonstrated concretely.

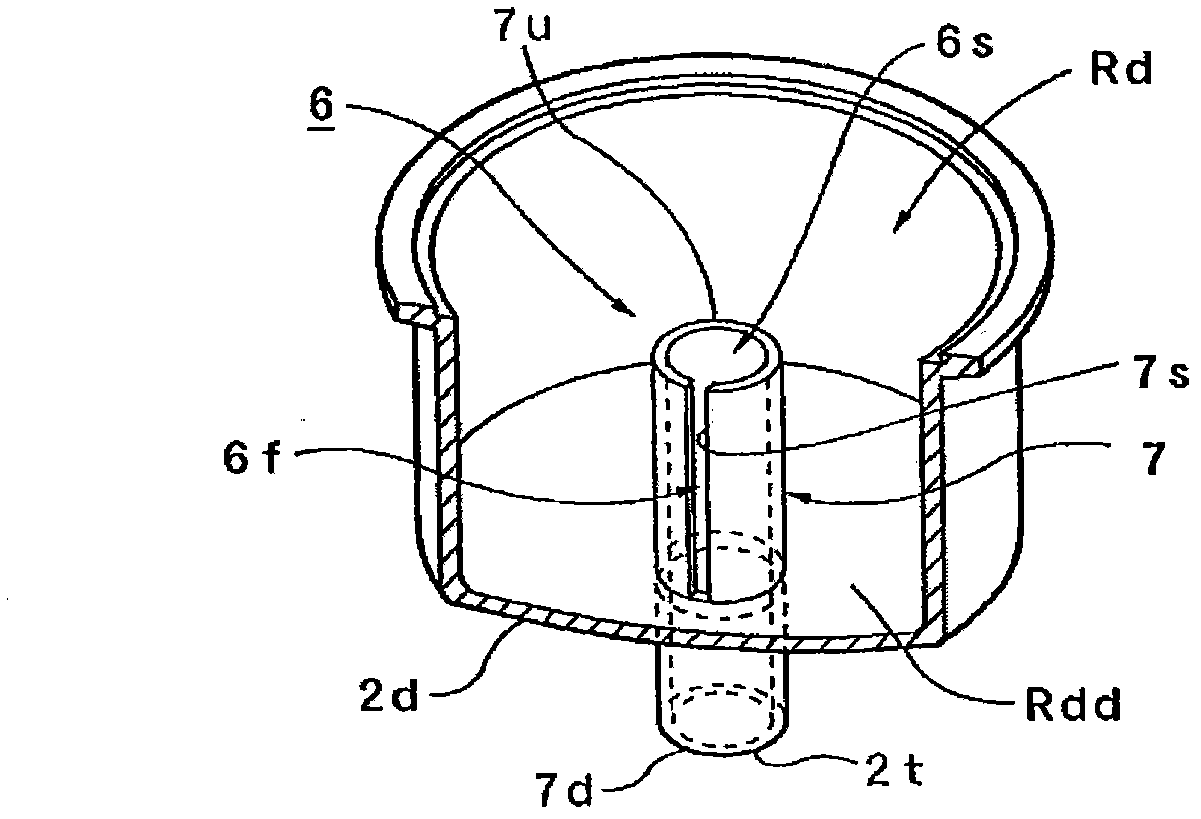

[0050] figure 1The milk meter main body 1m in the milk meter 1 is shown. Reference numeral 2 is a measuring container part, which is formed into a cylindrical shape as a whole by transparent or translucent plastic or glass, and two upper and lower narrowing parts 2su, 2sd, That is, the lowermost constricted portion 2sd and the secondary constricted portion 2su located above the constricted portion 2sd. Thus, the upper part of the measuring container part 2 than the narrowed part 2su is the gas-liquid separation chamber Rs, the part between the narrowed part 2su and the narrowed part 2sd is the measuring chamber Rm, and the part on the lower side than the narrowed part 2sd is the gas-liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com