Data communication method between welding power sources and computers

A technology of welding power supply and data communication, which is applied in the field of data communication between welding power supply and computer, and data communication between welding power supply and computer, which can solve the problem of limitation, inability to receive and process files normally, and blocking of welding power supply and computer LAN network, etc. problems, to avoid network congestion, reduce hardware resource costs, and improve transmission reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

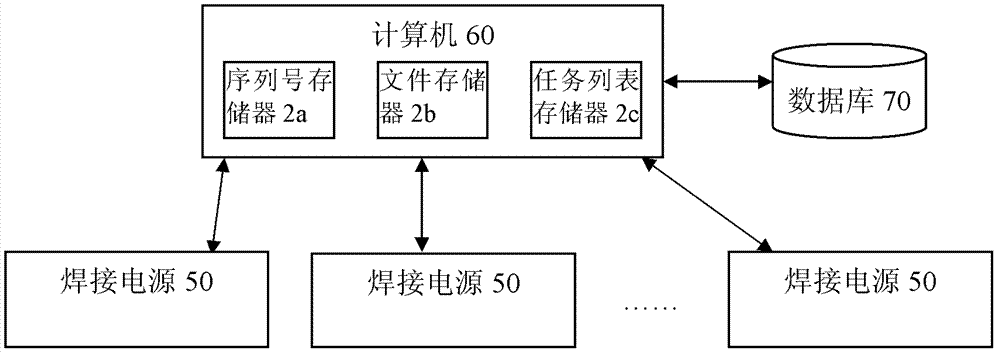

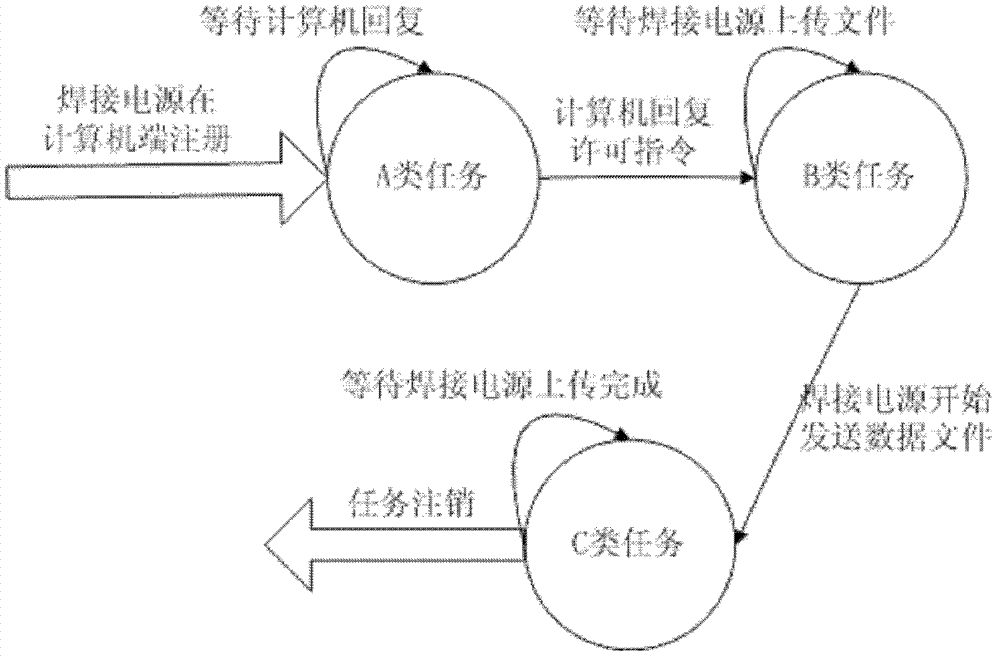

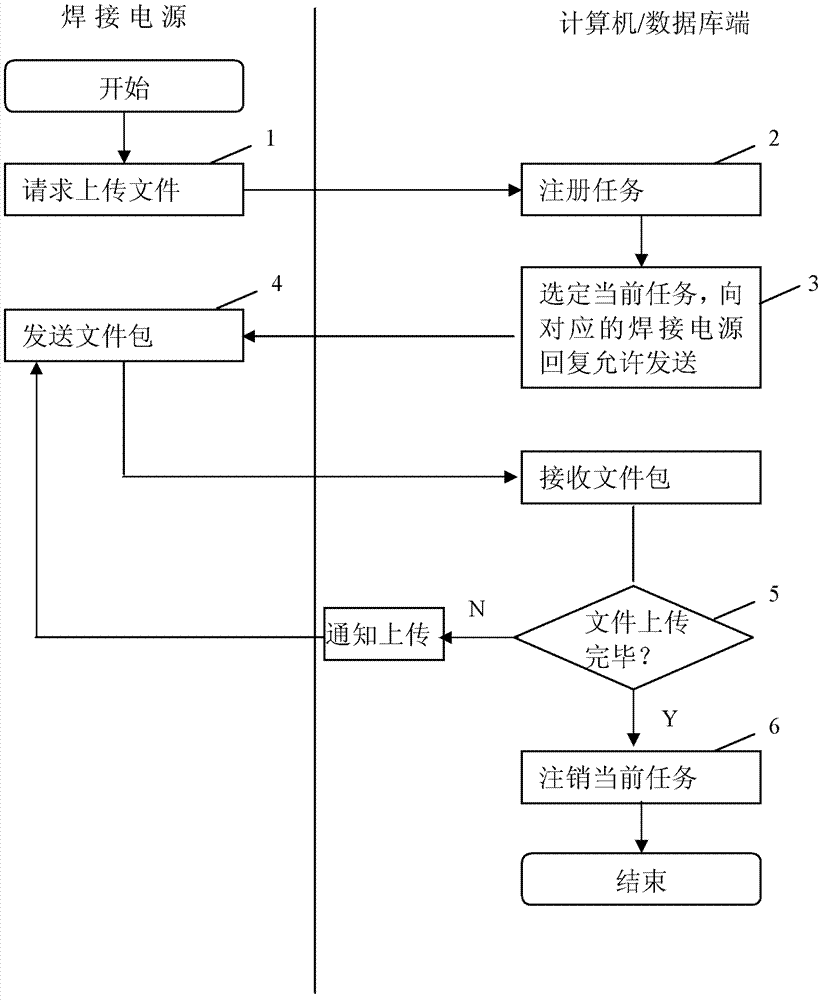

[0043] image 3 An overall flowchart of the first embodiment of the present invention is shown. The data communication method between the welding power source and the computer of the first embodiment includes the following steps.

[0044] Step 1: The welding power source requests to send file data (task request).

[0045] In this embodiment, as long as the welding power source 50 is connected to the network, it periodically requests the computer 60 to upload file data (file package). In this embodiment, the request cycle is set to be the same as the file generation cycle of the file generated by the welding power source, both of which are 3 minutes. It can be understood that the request period can also be set to be twice as long as the file generation period according to the actual situation. If within 3 minutes, received the upload permission reply of computer 60, then welding power supply 50 starts uploading; ask.

[0046] According to actual needs, instead of sending t...

no. 2 example

[0124] For the sake of brevity, only the aspects of the second embodiment that are different from the first embodiment are described below.

[0125] Such as Figure 10 As shown, after the computer 60 performs task registration as in step 2 of the first embodiment, in step 3a, it is judged from all records of the same ID that the record that is registered later is selected as the current task, and the process is performed. .

[0126] As described in the first embodiment, the task registration in step 2 may generate multiple records for the same ID. When the computer 60 selects the current task, it compares the registration time or the number of files of each record with the same ID, and the record with the later registration time or the largest number of files is selected by the computer 60 as the current task for processing.

[0127] Simultaneously, since the record registered later includes the file serial number of the record registered earlier, the computer 60 has execute...

no. 3 example

[0130] For the sake of brevity, only the aspects of the third embodiment that are different from the first embodiment will be described below.

[0131] Figure 11 with Figure 12 A registration task flow 2a different from the registration task flow 2 in the first embodiment is shown. In step 25a, for the records that have been responded to, that is, the records being processed, it is judged whether an upload abnormality occurs. If there is an exception, delete the existing record and add the current upload request to the task list. If there is no exception, update the content of the existing record instead of adding a new record.

[0132] Specific as Figure 12 As shown, it is assumed that two task records with IDs 1 and 2 already exist in the task list of the computer 60 . Among them, the number of files recorded by the task with ID=1 is 300, and the registration time and execution time are T30 respectively, that is, it is in the unresponsive state. At this time, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com