Camera calibration method for large field-of-view high-accuracy vision measurement

A camera calibration and visual measurement technology, applied in the field of testing and measurement, can solve the problems that small-sized targets cannot cover the measurement space, the calibration results cannot truly reflect the camera imaging model, and high-precision physical targets cannot be produced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

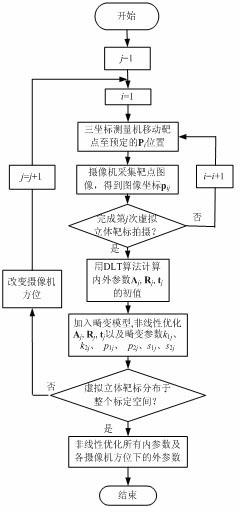

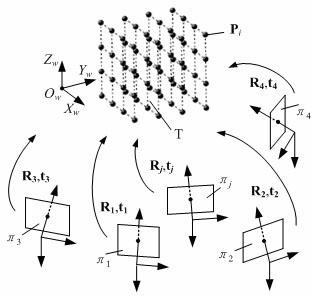

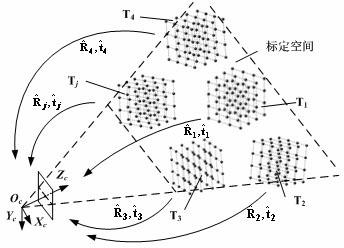

[0047] An infrared LED target point is fixed on the three-dimensional numerical control mobile device, and the three-dimensional numerical control mobile device can be a three-coordinate measuring machine or a three-coordinate milling machine. Set the coordinate system of the 3D NC mobile device as the world coordinate system. Fix the camera at the jth (j=1, 2, ..., m) shooting position according to the size of the measurement space, and the three-dimensional numerical control moving device moves according to the preset point, and every time the target point moves to a predetermined position P i (i=1, 2, ..., n), the camera collects a target image, thereby forming a virtual three-dimensional target and two images of the virtual three-dimensional target in the j-th shooting orientation in the moving space of the three-dimensional numerical control mobile device. Dimensional images (such as figure 2 shown). figure 2 The symbol T in the middle represents the virtual three-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com