Steel reed dent measurement device

A measuring device and reed technology, applied in the direction of instruments, counting mechanisms/items, etc., to achieve the effects of strong anti-interference, accurate counting results, and improved accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

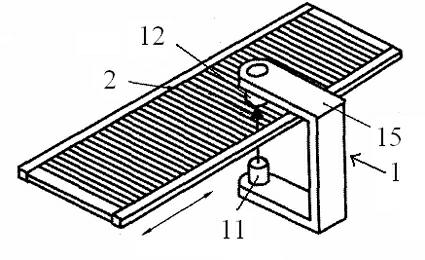

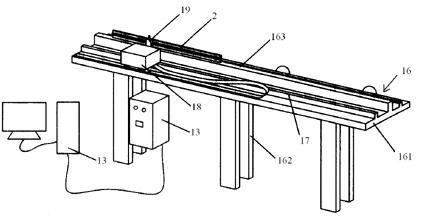

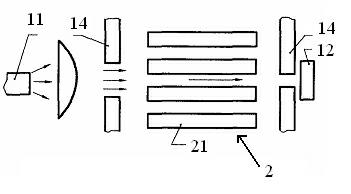

[0015] figure 1 Shown is a partial schematic view of the reed tooth measuring device provided by the present invention. figure 2 Shown is a schematic diagram of the reed tooth measuring device provided by the present invention. image 3 Shown is a schematic diagram of the principle of the reed tooth measuring device provided by the present invention. Please also refer to Figure 1 to Figure 3 .

[0016] The invention provides a reed tooth measuring device 1 for measuring the number of reed teeth of a steel reed 2 to be tested. The reed tooth measuring device 1 includes a beam emitting element 11 , a photosensitive receiving element 12 and a processing unit 13 . The beam emitting element 11 emits a laser beam. The beam emitting element 11 and the photosensitive receiving element 12 are respectively arranged on both sides of the reed 2 to be tested. The laser beam is emitted by the beam emitting element 11 and received by the photosensitive receiving element 12 after pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com