Detection apparatus of long stroke leading screw installation precision and application method thereof

A detection device and a technology for installation accuracy, applied in angle/taper measurement and other directions, can solve problems such as difficulty in obtaining side busbar parameters, and achieve the effect of verticality guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

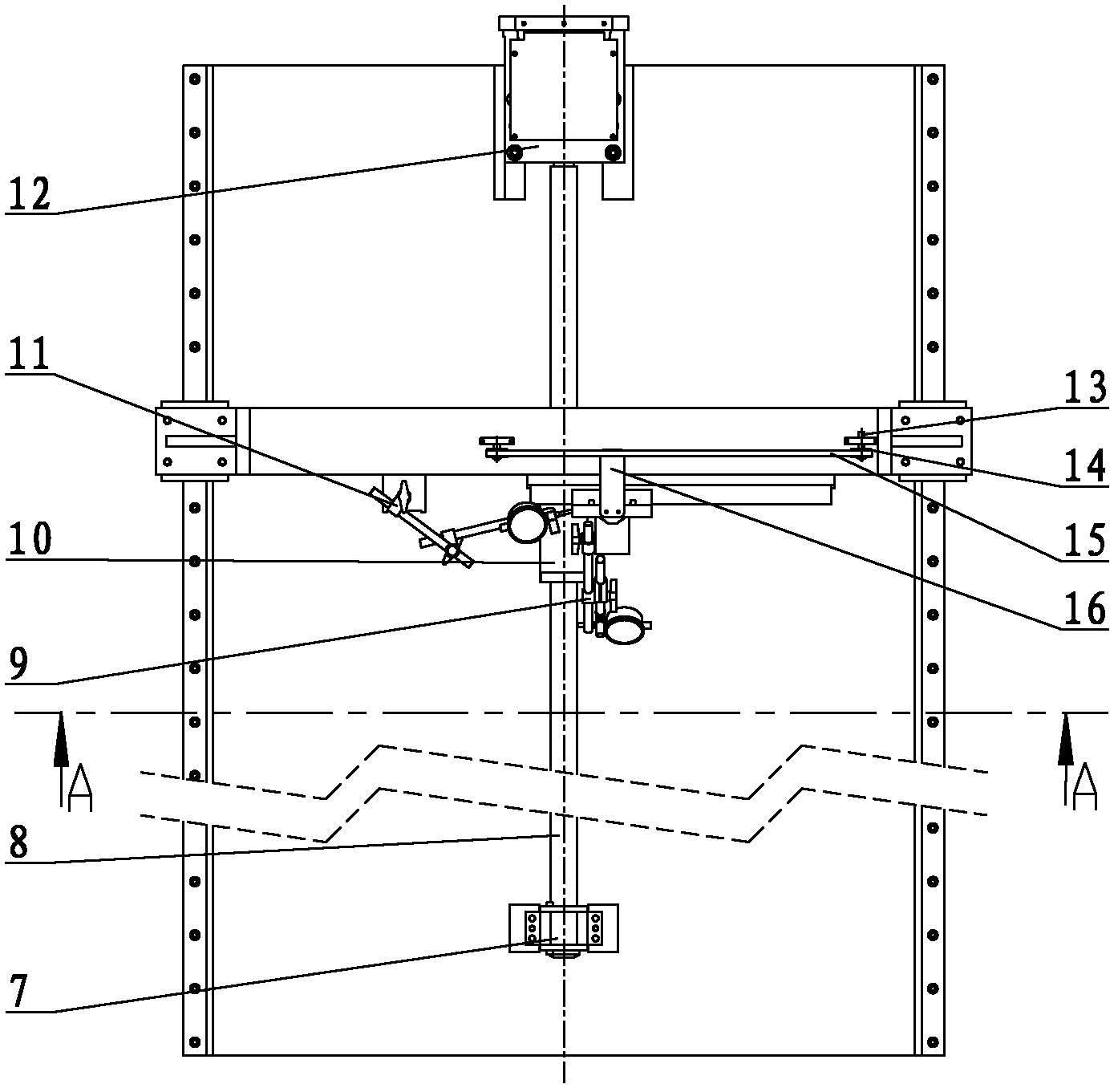

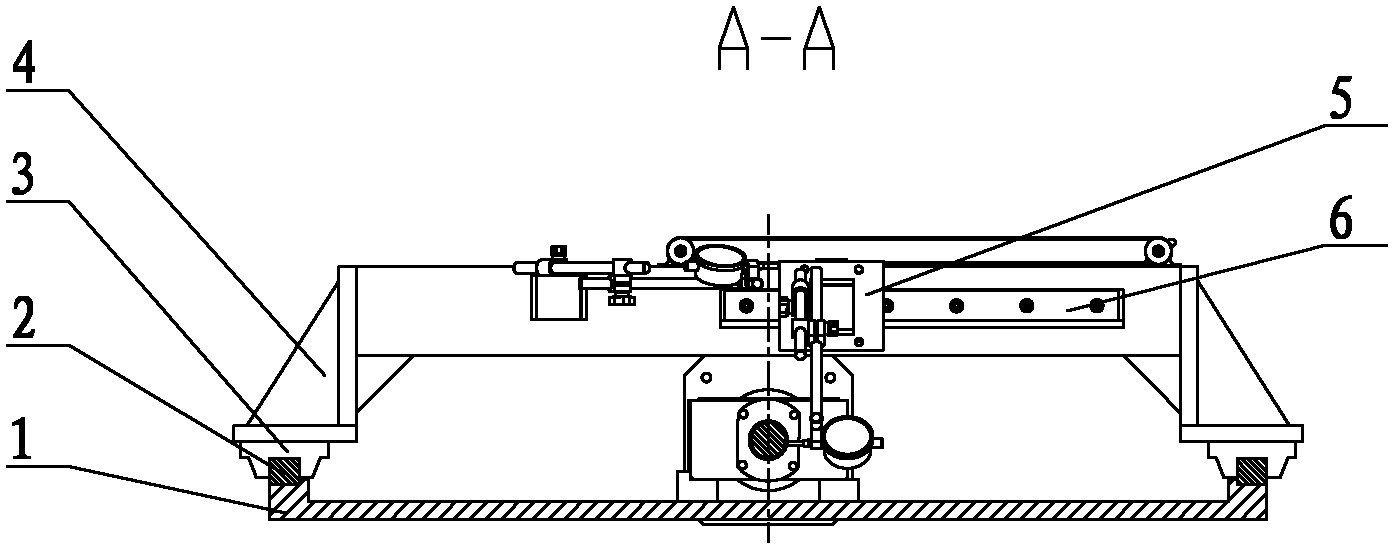

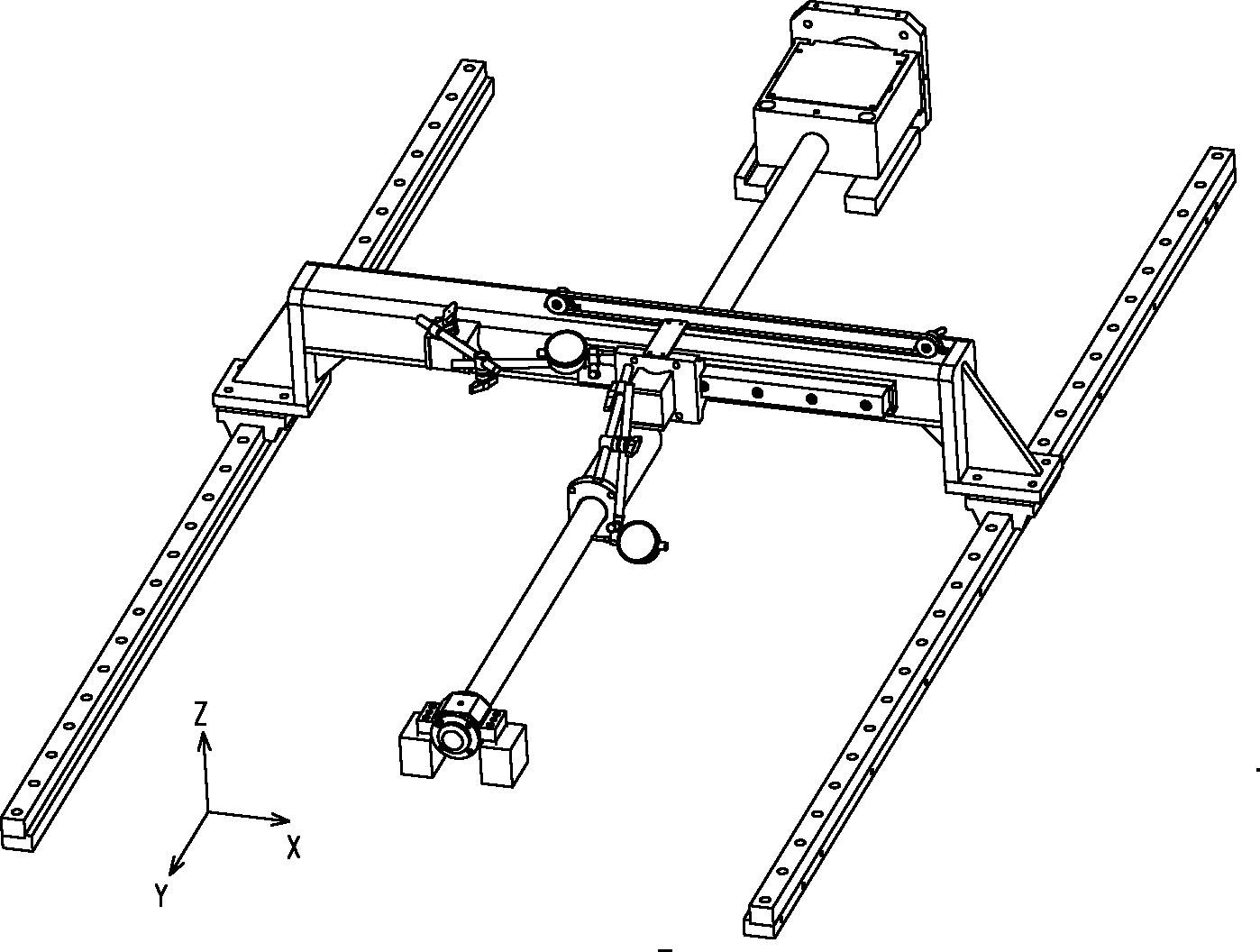

[0030] The present invention as Figure 1-3 As shown: the lead screw 8 is movably connected on the frame 1 through the lead screw bearing seat 7 and the lead screw motor seat 12, and the frame 1 is provided with a pair of Y guide rails 2 parallel to the lead screw 8 , the lead screw 8 is connected with a lead screw nut 10, and the detection device includes a gantry 4, an X-axis guide rail 6, an X-axis slider 5, a table 9 and a table 2 11;

[0031] The two feet of the gantry frame 4 are movably connected to the Y guide rail 2 through the Y-axis slider 3 respectively; it should be noted that the Y guide rail 2 is used as a beam guide rail after the machine tool is assembled, and here it is borrowed The rail is tested;

[0032] The X-axis guide rail 6 is fixedly connected to the side of the gantry 4 frame body, the X-axis guide rail 6 is horizontal, and its guide rail surface faces the direction of the screw bearing seat 7 or the direction of the screw motor seat 12;

[0033] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com