Prestressed tension auxiliary construction stage device

A prestressing and tensioning technology, which is applied in the direction of construction, building structure, and building materials processing, can solve problems such as failure to meet construction progress and construction safety, difficulty in lifting tension anchors in place, and affecting construction progress. Achieve the effect of material saving, simple structure and lower construction production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

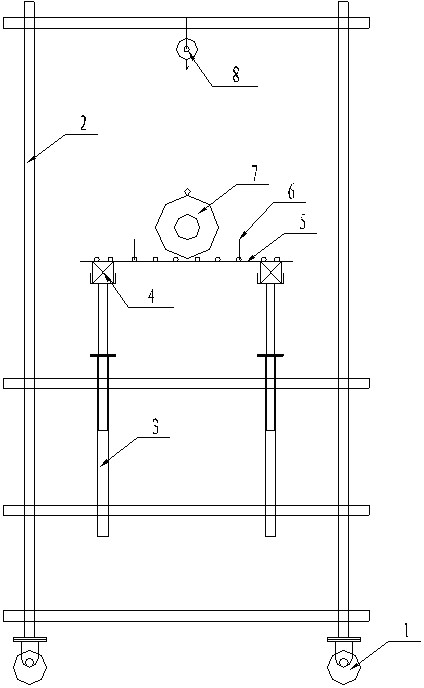

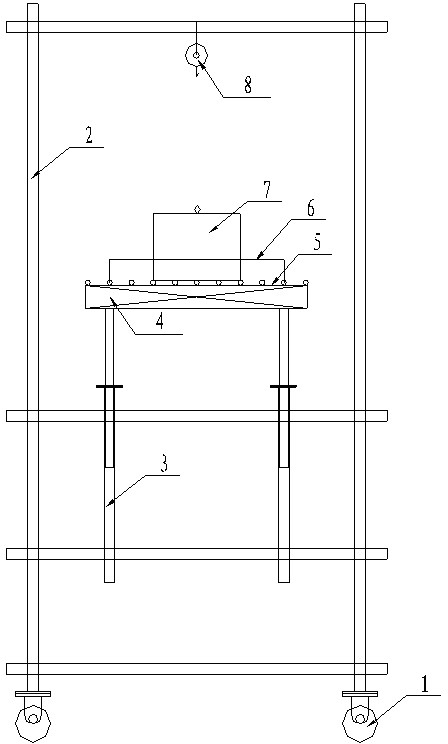

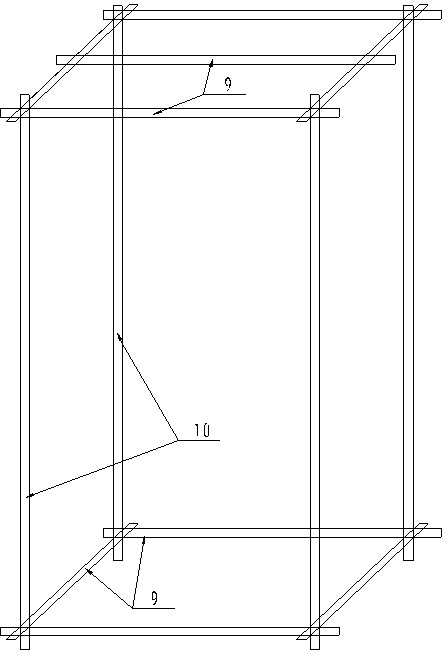

[0014] Such as figure 1 , figure 2 As shown, this stand device of the present invention is made up of outer formwork 2, inner formwork 3, anchorage pedestal 5, tension anchorage 7, pulley assembly 8; Outer formwork 2 and inner formwork 3 are made of scaffold steel pipe 9 . image 3 , as shown in Figure 4, the assembly is connected by scaffolding fasteners; the inner formwork 3 is placed in the outer formwork 2, the anchor pedestal 5 is placed on the inner formwork 3, and the tension anchor 7 is placed on the anchor pedestal 5, The pulley assembly 8 is connected on the outer formwork, and the bottom of the outer formwork 2 is provided with a universal rotating wheel 1, and its connection method is as follows: Figure 5 shown.

[0015] Anchor pedestal 5 is made up of square wood 4, steel mesh 14 and steel bar 6, and steel mesh 14 is placed on square wood 4, and steel bar 6 is placed on steel mesh 14, and square wood 4 is directly installed on jacking 13 superior. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com