Pile bottom grouting device

A grouting device and pile bottom technology, applied in construction, infrastructure engineering and other directions, can solve problems such as affecting construction, not tight enough connection, and prone to slurry leakage, so as to ensure normal construction, not easy to leak, and convenient for construction injection. pulp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

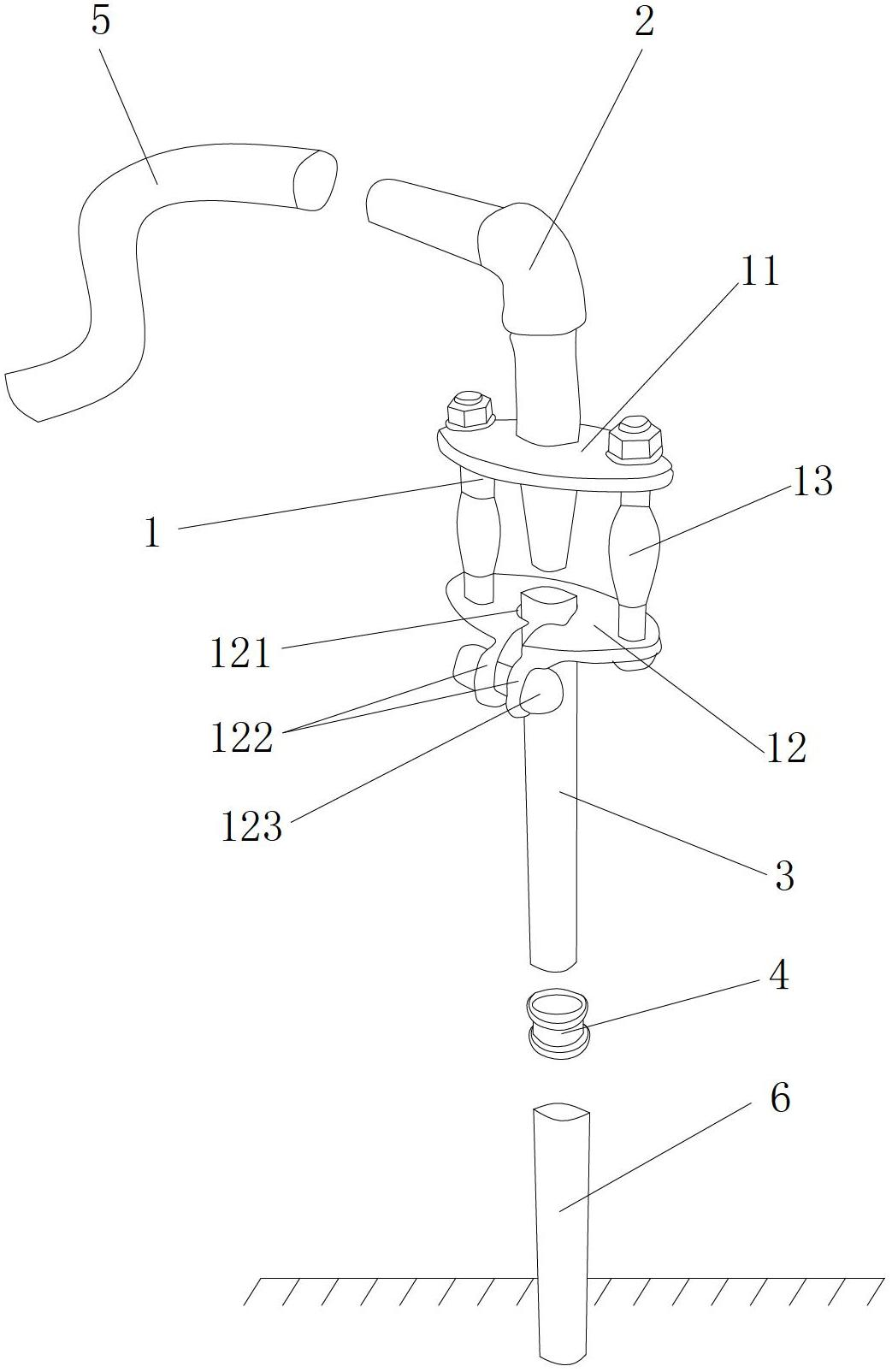

[0012] Such as figure 1 As shown, a pile bottom grouting device includes a bracket 1, a grouting joint pipe 2 arranged on the upper part of the bracket 1, and a detachable grouting tool whose upper end at the lower part of the bracket 1 communicates with the lower end of the grouting joint pipe 2 Pipe 3, the upper end of the grouting joint pipe 2 is connected to the grouting pipe 5, and the lower end of the grouting tool pipe 3 is connected to the grouting pipe 6 in the pile. The support 1 includes an upper support plate 11 for fixing the slurry joint pipe 2 , a lower support plate 12 for clamping the grouting tool pipe 3 , and a fixing rod 13 for connecting the upper support plate 11 and the lower support plate 12 . The lower support plate 12 is provided with an opening slot 121 for clamping the grouting tool pipe 3, and both sides of the opening of the opening slot 121 are provided with clamping shrapnel 122 on the lower support plate 12. The clamping elastic pieces 122 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com