Comprehensive treatment and resource recycling method for wine brewing wastes

A technology of comprehensive treatment and resource recovery, applied in the field of waste treatment, can solve the problems such as the energy that cannot be nearly offset for brewing, the energy that cannot be recovered and the energy consumed that cannot be recovered, etc., to improve fermentation efficiency, control feeding amount, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

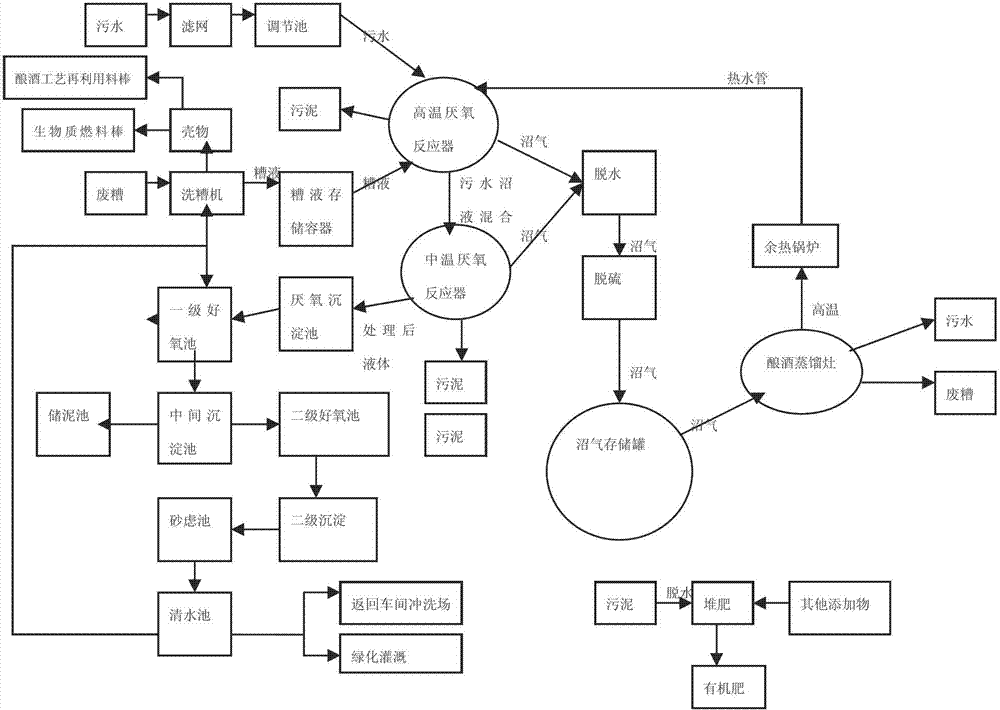

[0056] See figure 1 as shown,

[0057] First of all, the sewage and waste grains produced by the wine distillation stove are recovered, wherein the sewage enters the high-temperature anaerobic reactor after being filtered by a filter screen and the regulating tank; Separation and cleaning device for distiller's grains and shells. The waste grains are separated into shells and liquids through the waste washing machine. The liquids enter the storage container of the liquids and are put into the high-temperature anaerobic reactor as required. The shells are made by carbonization. Carbon rods provide fuel for wine distillation stoves.

[0058]Then the bad liquid and sewage are subjected to liquid fermentation through the high-temperature anaerobic reactor, and the sewage biogas slurry mixture fermented by the high-temperature anaerobic reactor enters the medium-temperature anaerobic reactor for fermentation again, and the heat required by the high-temperature anaerobic reactor pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com