Anticlockwise-rotation braking mechanism of electric bicycle

A technology for electric bicycles and brake mechanisms, applied in bicycle accessories, bicycle control systems, vehicle components, etc., can solve the problems of increased risk and unreliable application, and achieve the effects of convenient driving, obvious effects, and safe braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the structure, features and functions of the present invention in detail, two preferred embodiments are listed and described in conjunction with the following figures.

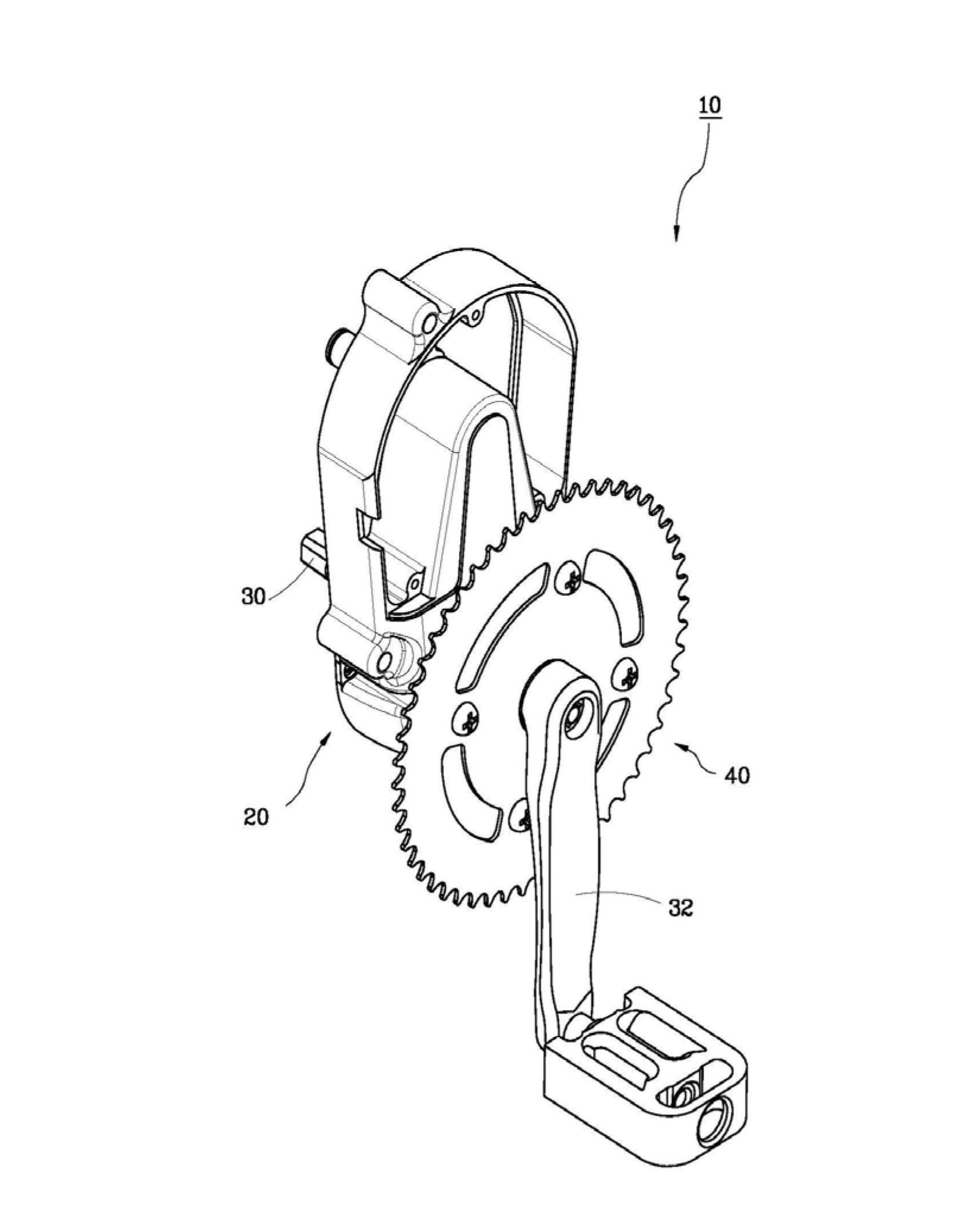

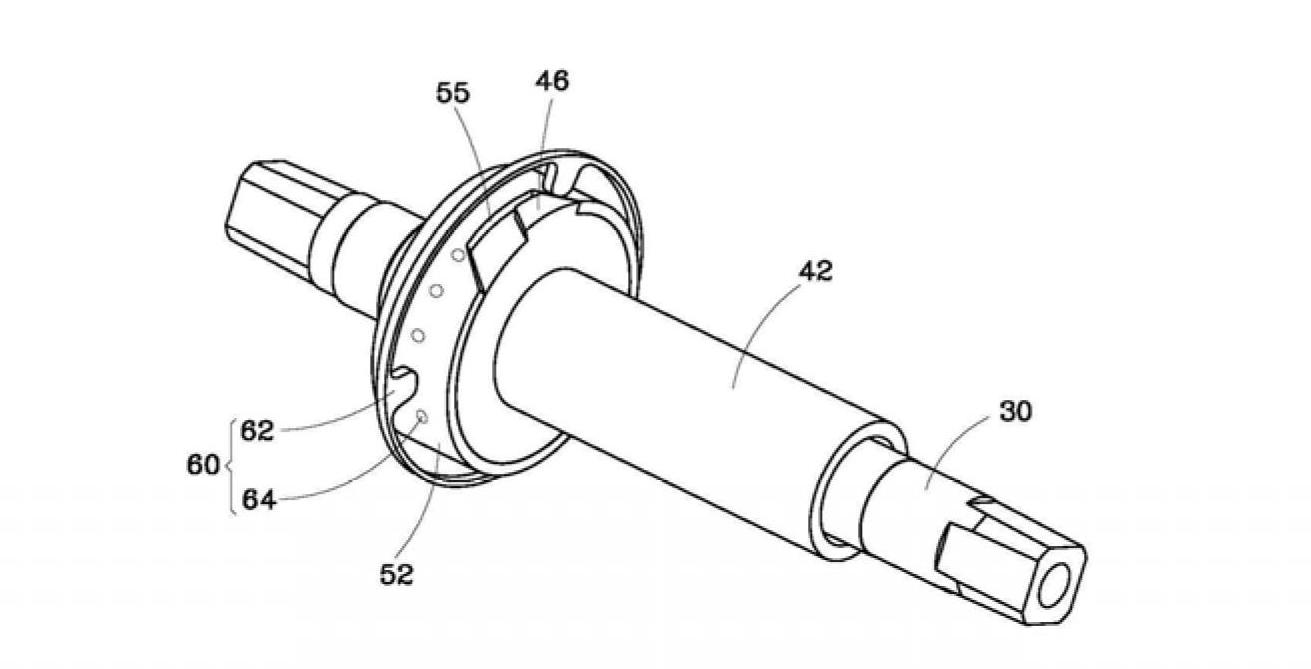

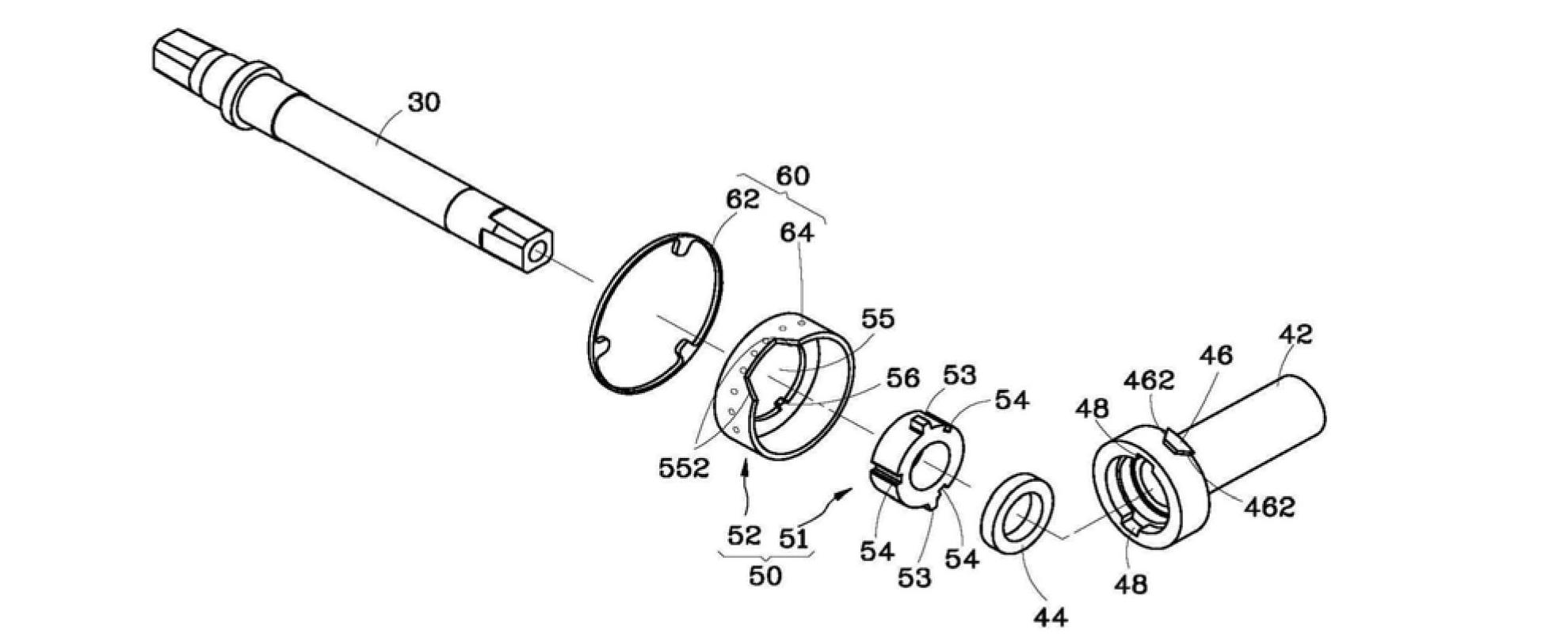

[0039] see Figure 1 to Figure 3 , the reverse braking mechanism 10 provided by the first preferred embodiment of the present invention is mainly used in electric bicycles, and includes a motor 20, a crankshaft 30, a large chainring 40, a clutch 50, and a sensor 60 .

[0040] The motor 20 is installed on the frame of the electric bicycle to provide power assistance. Since the motor 20 is a common structure for those skilled in the art, it will not be described in detail here.

[0041] The crankshaft 30 passes through the motor 20 and is connected to a crank 32 at its two ends, which can be rotated forward or reversed relative to the motor 20 by an external force.

[0042] The large tooth plate 40 has a sleeve 42, the sleeve 42 is rotatably sleeved on the crankshaft 30 by a bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com