Method for ammonia method desulfurization of flue gas and high-purity solid ammonium sulfite by-producing

A technology for ammonium sulfite and ammonia desulfurization, which is applied in ammonium sulfite, separation methods, chemical instruments and methods, etc., can solve the problem of high cost, comprehensive utilization of resources and environmental protection issues, and the number of products. limited issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

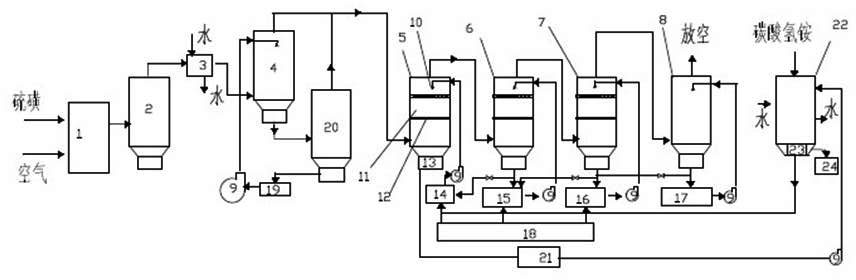

Image

Examples

Embodiment 1

[0025] Example 1: Simulated flue gas composition: 78% N 2 , 3% O 2 , 15% SO 2 , 3% CO 2 and water vapor. Flue gas flow: 1m 3 / min. The ammonia water and (NH 4 ) 2 SO 3 The pH value of the solution is 5-6; the ammonia water and (NH 4 ) 2 SO 3 The pH value of the solution is 6-7; the ammonia water and (NH 4 ) 2 SO 3 The pH value of the solution is 6-7. test results:

[0026] Flue gas flow rate (m 3 / min) SO after purification 2 Content (ppm) Purified NH 3 Content (ppm) Impurity content in solid ammonium sulfite 1 58 32 5%

Embodiment 2

[0027] Example 2: Simulated flue gas composition: 78% N 2 , 4% O 2 , 10% SO 2 , 7% CO 2 and water vapor. Flue gas flow: 1m 3 / min. The ammonia water and (NH 4 ) 2 SO 3 The pH value of the solution is 5-6; the ammonia water and (NH 4 ) 2 SO 3 The pH value of the solution is 6-7; the ammonia water and (NH 4 ) 2 SO 3 The pH value of the solution is 6-7. test results:

[0028] Flue gas flow rate (m 3 / min) SO after purification 2 Content (ppm) Purified NH 3 Content (ppm) Impurity content in solid ammonium sulfite 1 65 28 4%

Embodiment 3

[0029] Example 3: Composition of simulated flue gas: 78% N 2 , 8% O 2 , 7% SO 2 , 5% CO 2 and water vapor. Flue gas flow: 1m 3 / min. The ammonia water and (NH 4 ) 2 SO 3 The pH value of the solution is 6-7; the ammonia water and (NH 4 ) 2 SO 3 The pH value of the solution is 6-7; the ammonia water and (NH 4 ) 2 SO 3 The pH value of the solution is 6-7. test results:

[0030] Flue gas flow rate (m 3 / min) SO after purification 2 Content (ppm) Purified NH 3 Content (ppm) Impurity content in solid ammonium sulfite 1 58 62 5%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com