Fine filter device of high pressure back-flush rotary filter drum

A technology of rotating filter cartridges and high-pressure backflushing, which is applied to fixed filter element filters, filtration separation, chemical instruments and methods, etc. It can solve the problems of changing nozzle injection speed, reducing injection momentum and cooling effect, and reducing work efficiency. Achieve the effects of improving filtration accuracy, facilitating daily maintenance, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to fully understand the technical content of the present invention, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

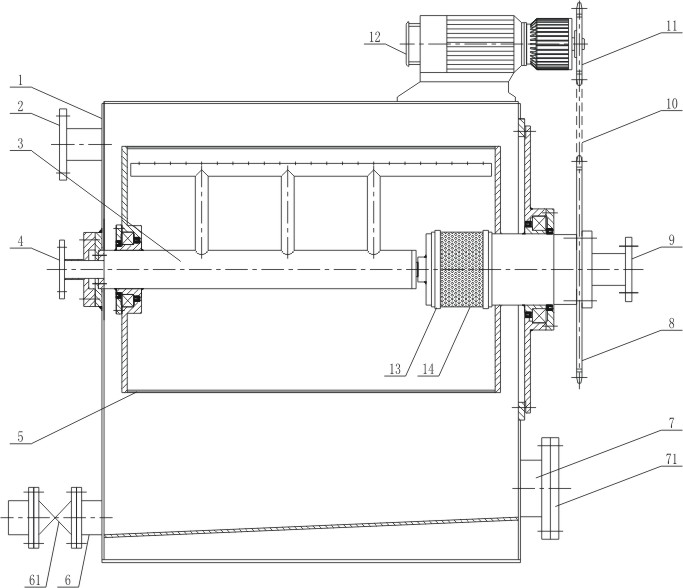

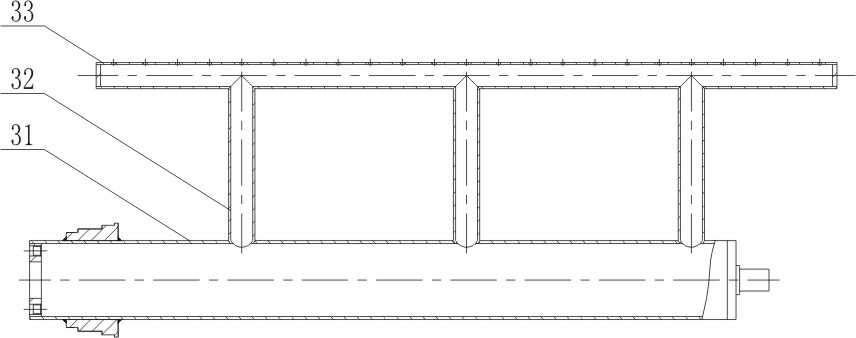

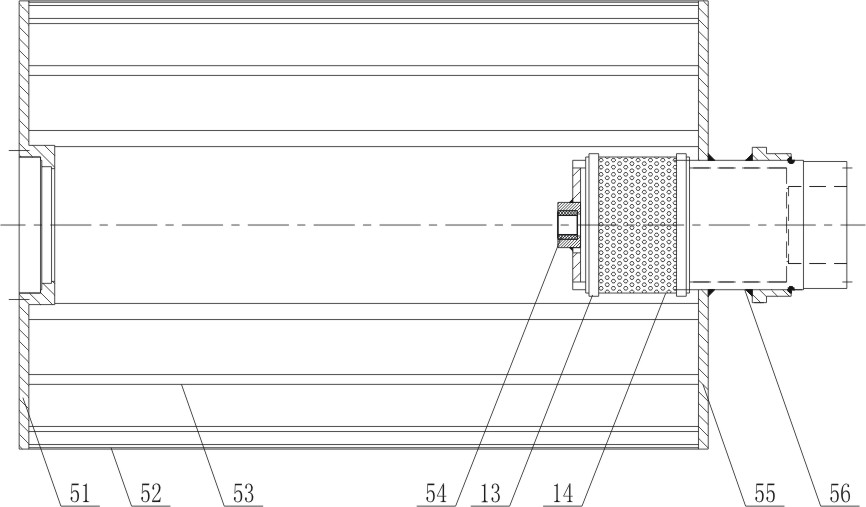

[0024] Such as figure 1 As shown, a fine filter device for a high-pressure recoil rotary filter cartridge includes a housing 1, a filter cartridge 5, a sewage inlet pipe 2 arranged at the upper part of the water inlet side of the housing 1, and a sewage inlet pipe 2 arranged at the bottom of the water inlet side of the housing 1. The blowdown pipe 6 and the supporting seat arranged in the middle of the water inlet side of the housing 1, the backflush water inlet pipe 4 is fixed on the supporting seat through bolts, and the outlet pipe 9 is arranged on the opposite side of the backflush water inlet pipe 4; wherein, the blowdown pipe 6 and the blowdown valve 61 are connected to the outer side of the housing 1 through a flange seal, and a flushing pipe 7 is provided at the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com