Preparation of ethofenprox film-spreading oil solution and application of ethofenprox film-spreading oil solution on control of rice plant hopper

A film-expanding oil agent, etofenprox technology, applied in the application, insecticide, biocide, etc., can solve the problems that it is difficult to evenly distribute the active ingredients in water, pollute the environment, waste aquatic organisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

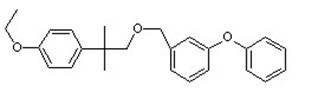

Image

Examples

Embodiment 1

[0022] 1% Etofenprox Film Spreading Oil

[0023] Take 1% Etofenprox by mass percentage, solvent methyl laurate 6%, surfactant alkylphenol polyoxyethylene tetraether (OP-4) 2%, alkylphenol polyoxyethylene decaether (OP-10) 2%, Nongru 2201 1%, lauryl alcohol ester 5%, soybean oil to make up to 100%. Under stirring at a temperature of 50-60°C and a rotation speed of 50-100 rpm, the etofenprox was completely dissolved in the solvent to obtain a 1% etofenprox spreading oil.

[0024] The prepared etofenfax film spreading oil has a transparent appearance, no precipitation, crystallization and stratification after 14 days of heat storage (54°C±2°C) and 7 days of low temperature storage (0°C±2°C), and the decomposition rate is 1.2% . The surface tension at 35°C is 21.7mN / m, and the oil / water interfacial tension when dripping on the water surface is 0.11mN / m; it can spread rapidly on the water surface. When the dripping amount is 3.6μL, the spreading speed is 10.4cm / s. The spreading ...

Embodiment 2

[0026] 2.5% Etofenprox film developing oil

[0027] Take 2.5% Etofenprox by mass percentage, solvent methyl laurate 15%, surfactant alkylphenol polyoxyethylene tetraether (OP-4) 2%, alkylphenol polyoxyethylene decaether (OP-10) 2%, Nongru 2201 2%, lauryl alcohol ester 5%, soybean oil to make up to 100%. Under stirring at a temperature of 50-60°C and a rotation speed of 50-100 rpm, the etofenprox was completely dissolved in the solvent to obtain a 2.5% etofenprox spreading oil.

[0028] The prepared Etofenprox film spreading oil has a transparent appearance, and after heat storage (54°C±2°C) for 14 days and low temperature storage (0°C±2°C) for 7 days, there is no precipitation, crystallization and delamination, and the decomposition rate is 1.8% . The surface tension at 35°C is 24.1mN / m, and the oil / water interfacial tension when dripping on the water surface is 0.17mN / m; it can spread rapidly on the water surface, and the spreading speed is 8.2cm / s when the dripping amount ...

Embodiment 3

[0030] 5% Etofenprox Film Spreading Oil

[0031] Take 5% Etofenprox by mass percentage, solvent methyl laurate 20%, surfactant alkylphenol polyoxyethylene tetraether (OP-4) 4%, alkylphenol polyoxyethylene decaether (OP-10) 4%, Nongru 2201 4%, lauryl alcohol ester 5%, soybean oil to make up to 100%. Under stirring at a temperature of 50-60°C and a rotation speed of 50-100 rpm, the etofenprox was completely dissolved in the solvent to obtain a 5% etofenprox spreading oil.

[0032] The prepared Etofenprox film spreading oil has a transparent appearance, no precipitation, crystallization and stratification after 14 days of heat storage (54°C±2°C) and 7 days of low temperature storage (0°C±2°C), and the decomposition rate is 1.5% . The surface tension at 35°C is 26.7mN / m, and the oil / water interfacial tension when dripping on the water surface is 0.25mN / m; it can spread rapidly on the water surface, and the spreading speed is 7.8cm / s when the dripping amount is 3.6μL. The spread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com