Memory device and manufacturing method therefor

A technology of a storage device and a manufacturing method, which is applied in information storage, static memory, digital memory information, etc., can solve the problems of uneven film thickness, abnormal shape, and uneven electrical characteristics of resistance change elements such as initial resistance value, etc., and achieve reduction Effect of less unevenness and initial resistance value unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

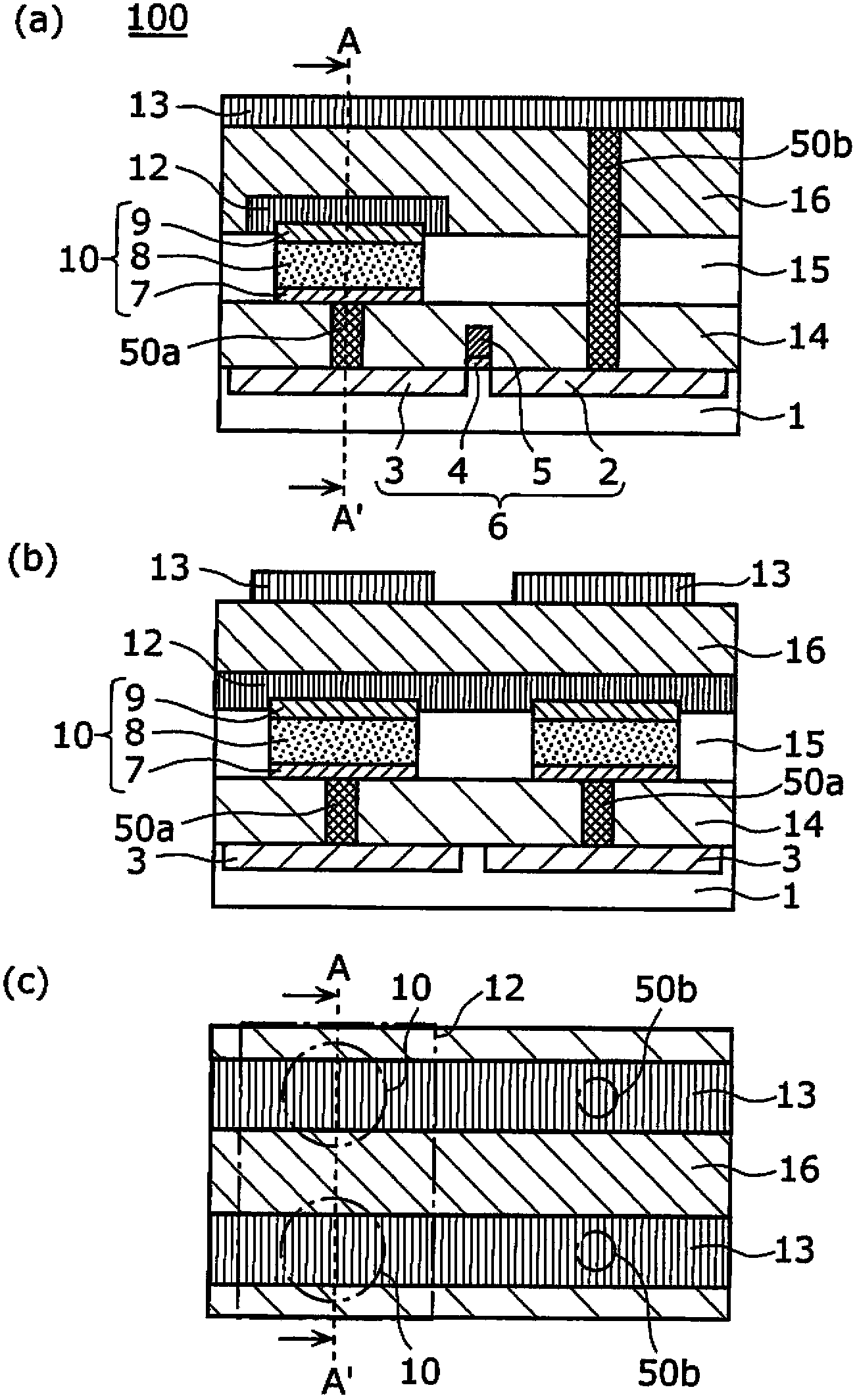

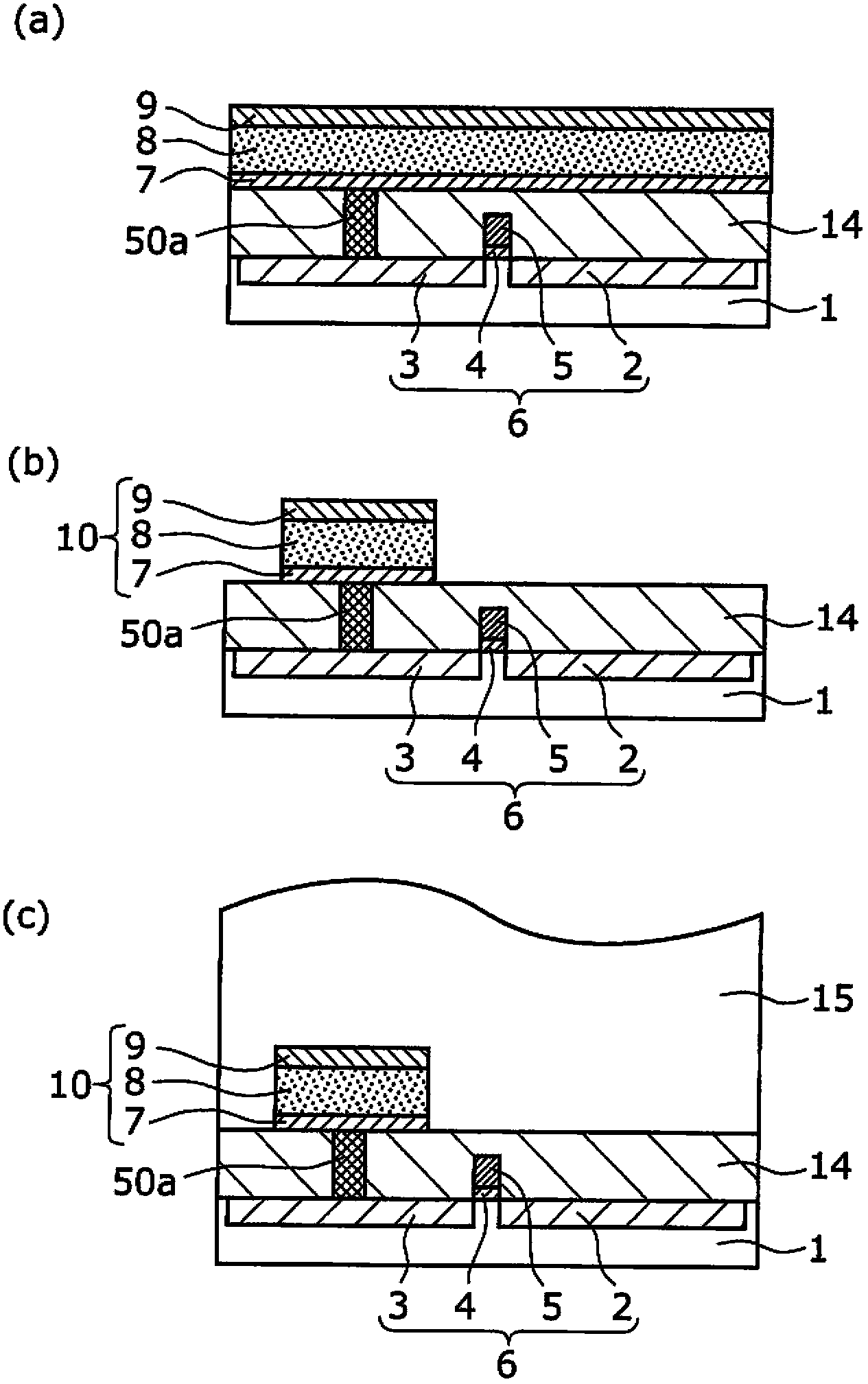

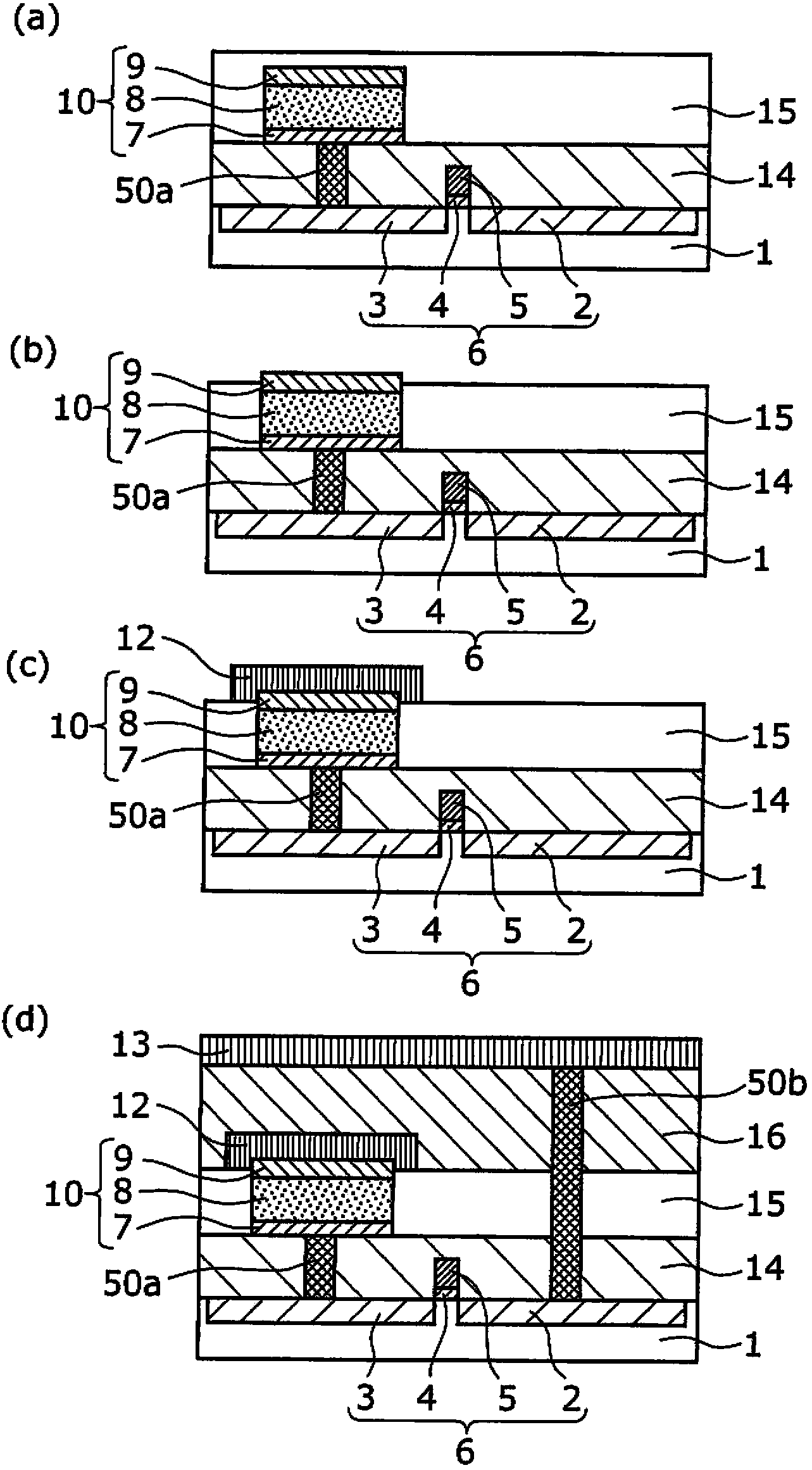

[0071] [Storage Device Configuration]

[0072] figure 1 is a schematic diagram of the storage device according to Embodiment 1, figure 1 (a) is a schematic cross-sectional view showing the configuration of the storage device 100 , figure 1 (b) is viewed from the direction of the arrow figure 1 (a) A schematic sectional view of the section along line A-A', figure 1 (c) is a schematic plan view of the same figure (a) viewed from the surface. In addition, in figure 1 In (c), some constituent elements of the memory device that are not visible on the surface are indicated by dashed-dotted lines and given reference numerals.

[0073] The memory device 100 includes a plurality of 1T1R memory cells. In detail, the memory cell is formed by connecting the selection transistor 6 and the variable resistance element 10 in series through the conductive via 50a. The selection transistor 6 is composed of the source region 2, the drain region 3, and the gate electrode 5. The source...

Embodiment approach 2

[0127] [Storage Device Configuration]

[0128] The memory device 200 of the second embodiment differs from the memory device 100 of the first embodiment in that when the lead wire 12 is formed, the metal wire 17 connected to other than the upper electrode 9 is formed simultaneously with the formation of the lead wire 12 . The other configurations are the same as those of the storage device 100 according to Embodiment 1, and therefore description thereof will be omitted.

[0129] Image 6 is a schematic diagram of the storage device 200 according to Embodiment 2, Image 6 (a) is a schematic cross-sectional view showing the configuration of the storage device 200 , Image 6 (b) Viewed from the direction of the arrow Image 6 (a) A schematic sectional view of the section along line BB', Image 6 (c) is a schematic plan view of the same figure (a) viewed from the surface. In addition, in Image 6 In (c), some constituent elements of the memory device that are not visible on ...

Embodiment approach 3

[0148] [Storage Device Configuration]

[0149] The memory device 300 of the third embodiment differs from the memory device 100 of the first embodiment in that the lead wiring 12 is in contact with the variable resistance layer 8 in addition to the upper electrode 9 of the variable resistance element 10 , and the other configurations are the same as those of the first embodiment. The storage device 100 is the same, so the description is omitted.

[0150] Figure 8 is a schematic diagram of the storage device 300 according to Embodiment 3, Figure 8 (a) is a schematic cross-sectional view showing the configuration of the storage device 300 . also, Figure 8 (b) is viewed from the direction of the arrow Figure 7 (a) Schematic sectional view of the section along line C-C'. exist Figure 8 (a), for Figure 1 ~ Figure 3 The same constituent elements are assigned the same reference numerals, and description thereof will be omitted.

[0151] The memory device 300 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com