Method and system for tracking quality of products in flow industry

A product quality and tracking system technology, applied in the direction of instruments, etc., can solve problems such as laborious and time-consuming, and achieve the effect of effectively guiding production and improving the effect of finding factors that affect product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

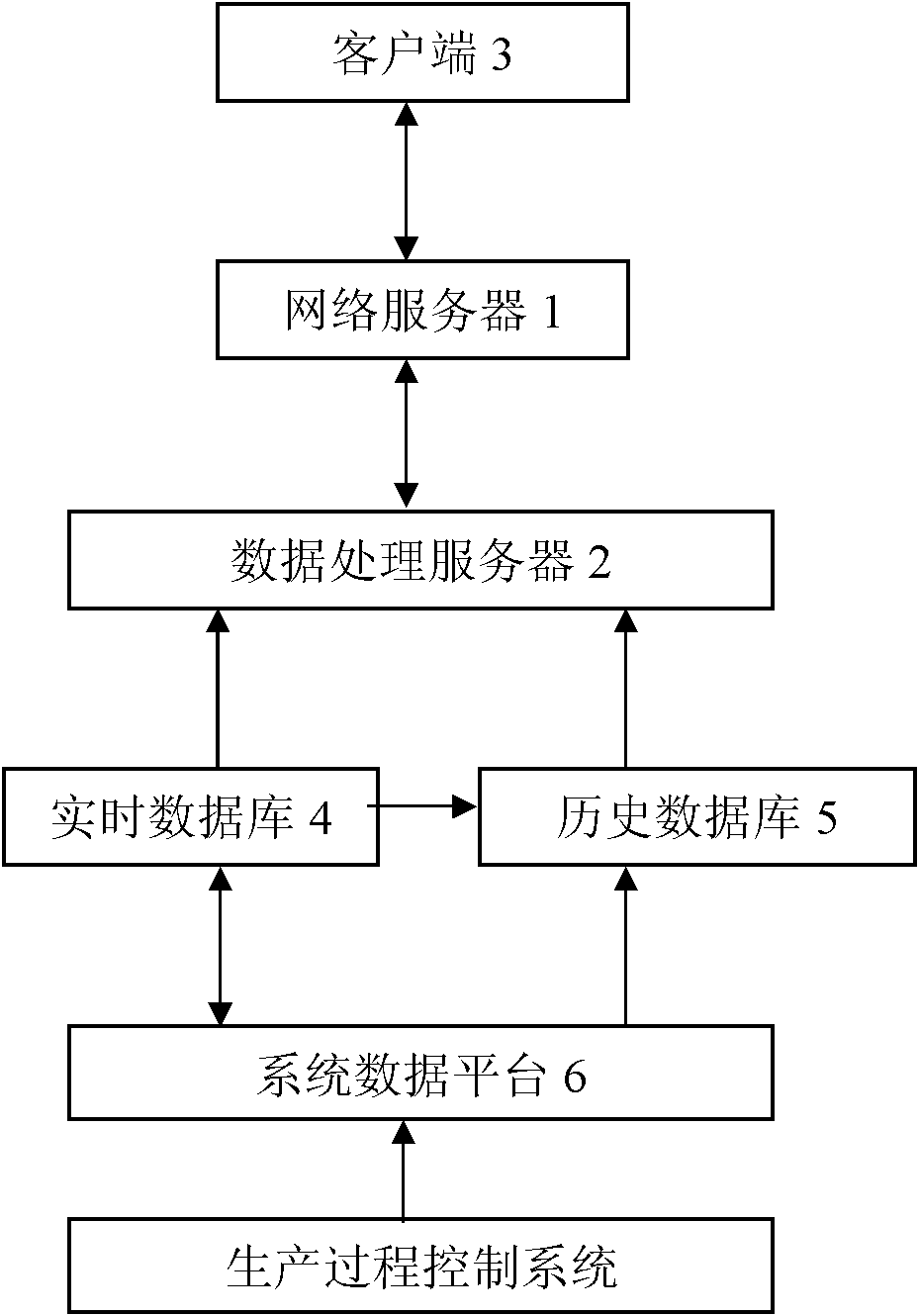

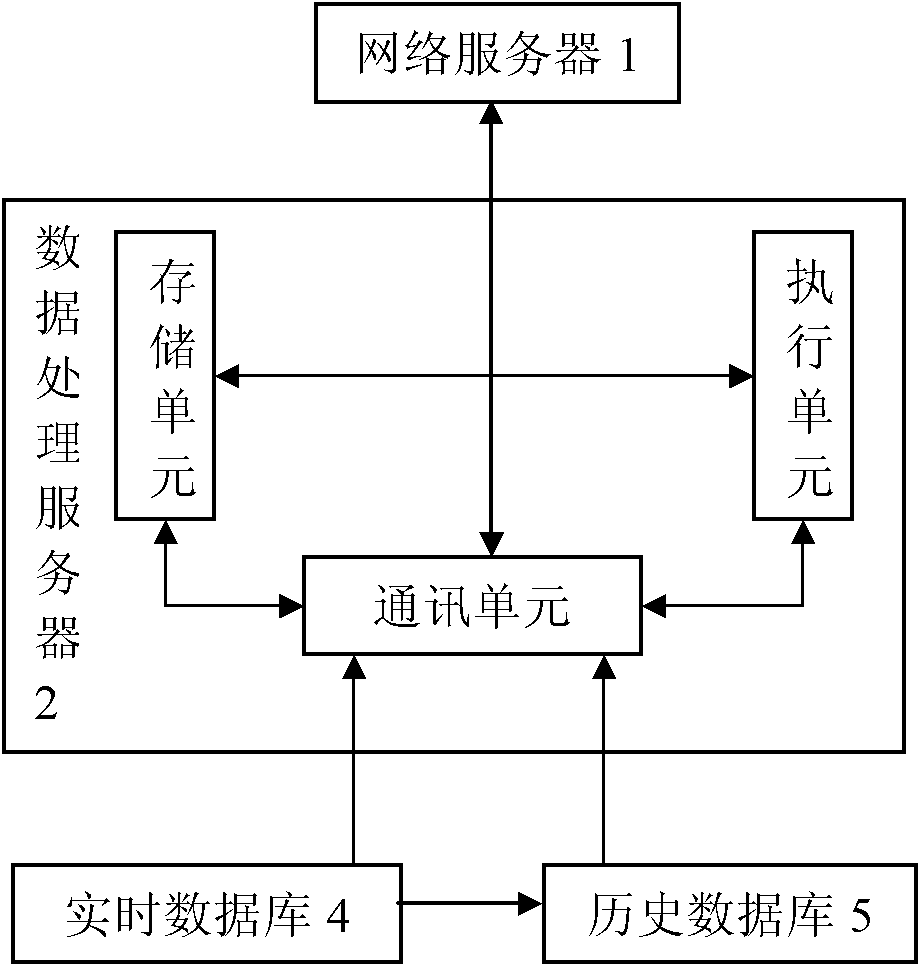

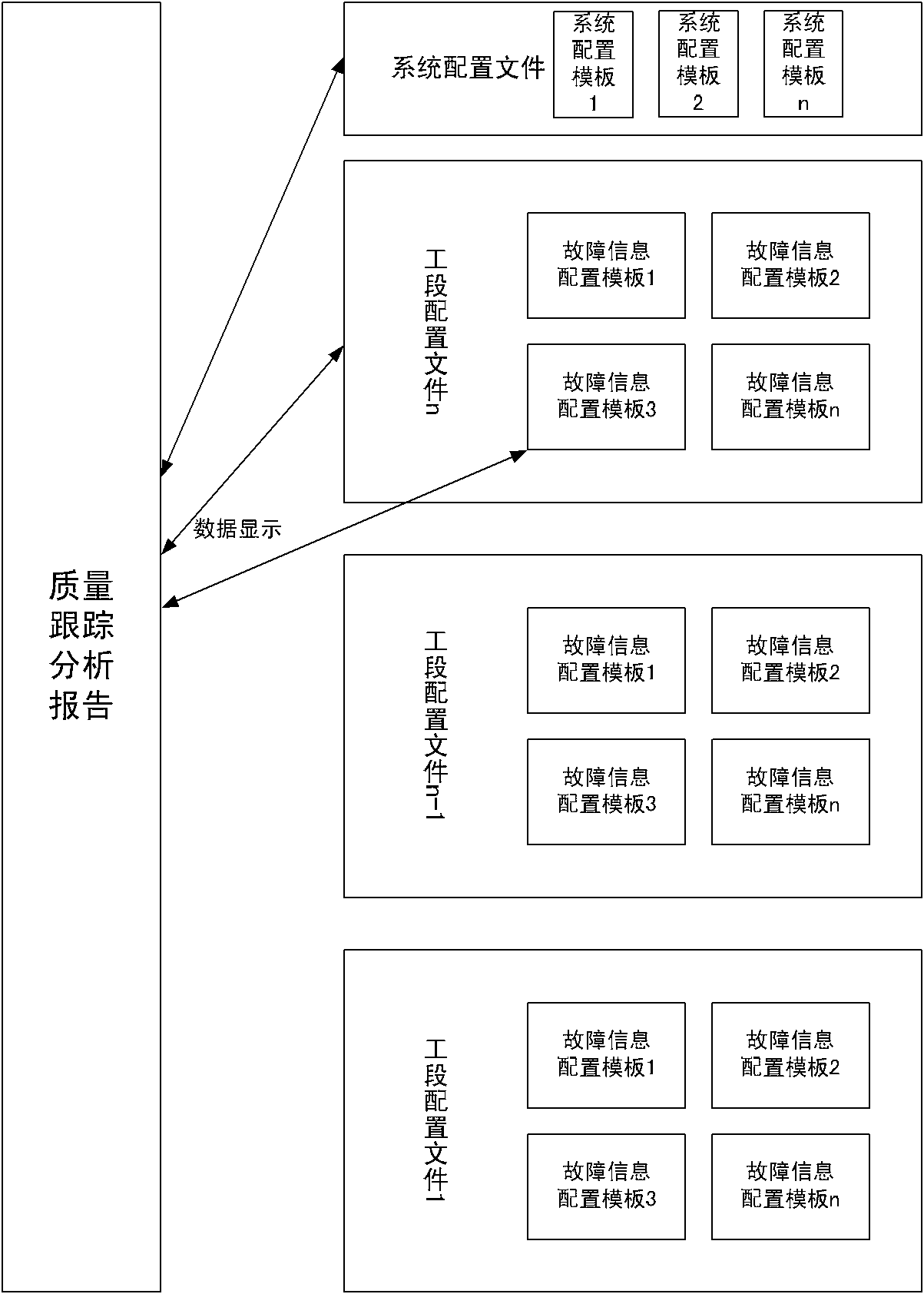

[0053] In order to automatically and efficiently track and locate failure events that affect product quality in the production process when product quality problems occur, a quality tracking system for the process industry has been established, such as Figure 1a As shown, it includes: a network server 1 , a data processing server 2 , a client 3 , a real-time database 4 , a historical database 5 , and a system data platform 6 .

[0054] The system data platform 6 refers to the platform for obtaining on-site production process data, which is connected with the on-site production process control system (such as DCS or PLC) through a communication network (such as industrial Ethernet) to collect and uniformly manage the on-site production process control system Production process data in . The production process data includes on-site real-time data, regularly collected or entered batch data and / or ERP and / or MES result record data; these production process data are classified and ...

specific Embodiment 2

[0079] The following takes the coke industry as an example to describe the quality tracking system and quality tracking method.

[0080] The quality tracking system of the coke industry is the same as that of Embodiment 1, only corresponding adjustments are made for the specific conditions of the coke industry. Specific implementation methods such as Figure 9a and Figure 9b shown.

[0081] Establishment of the material flow for the production process in the coke industry. like Figure 9a shown. The material flow of the coke industry includes unloading coal from various single raw materials to the coal yard, taking coal to each coal blending tank, and then crushing and blending to become blended coal, which is transported to the coal tower, and then enters the coke oven through coal charging operation. After coking, coke quenching and coke screening, it becomes the final product coke, which is supplied to the blast furnace system or other users. According to the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com