System and method for improving heat dissipation potential of heat sink

A technology of heat dissipation capacity and radiator, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., can solve the problem of not optimizing the distribution of outer fins, not considering the distribution of the air inlet wind speed of the cooling fan, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in combination with principle diagrams and specific operation examples.

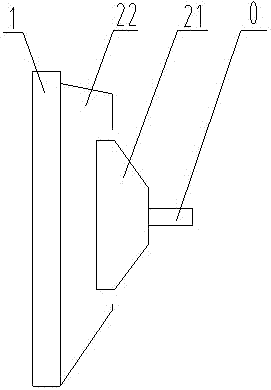

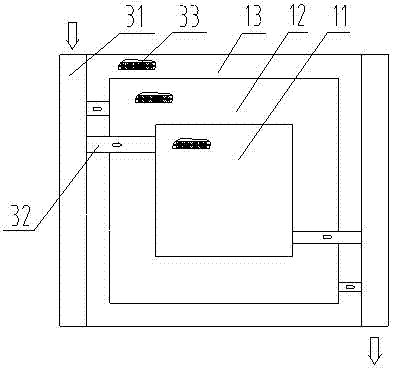

[0025] Such as figure 1 As shown, the system for improving the heat dissipation capacity of the radiator of the present invention includes a radiator assembly and a cooling fan 21, and the cooling fan 21 generates suction, so that the cold air used for heat dissipation passes through the radiator assembly. Preferably, the radiator assembly includes a radiator The core body 1 and the air guide cover 22, the air guide cover 22 is located between the radiator core body 1 and the cooling fan 21, the cooling fan 21 is connected to common driving components such as a motor through the fan shaft 0, under the action of the driving force, the fan shaft 0 drives the cooling fan 21 to rotate, and the external cold air then enters the air guide cover 22 and is finally introduced into the radiator core 1.

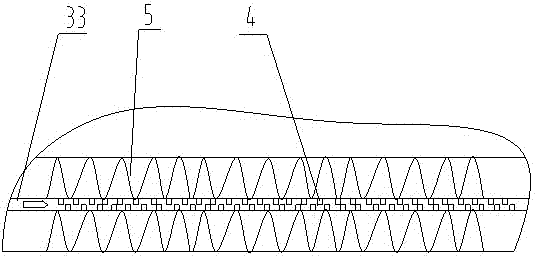

[0026] Radiator core 1 has several annular heat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com