Excavator bucket tooth

A technology of excavator bucket teeth and bucket teeth, which is applied in the field of bucket teeth and bucket teeth on excavators, can solve the problems of high cost of use, adverse effects of bucket teeth and tooth seats, and affecting work, and achieves strong practicability and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

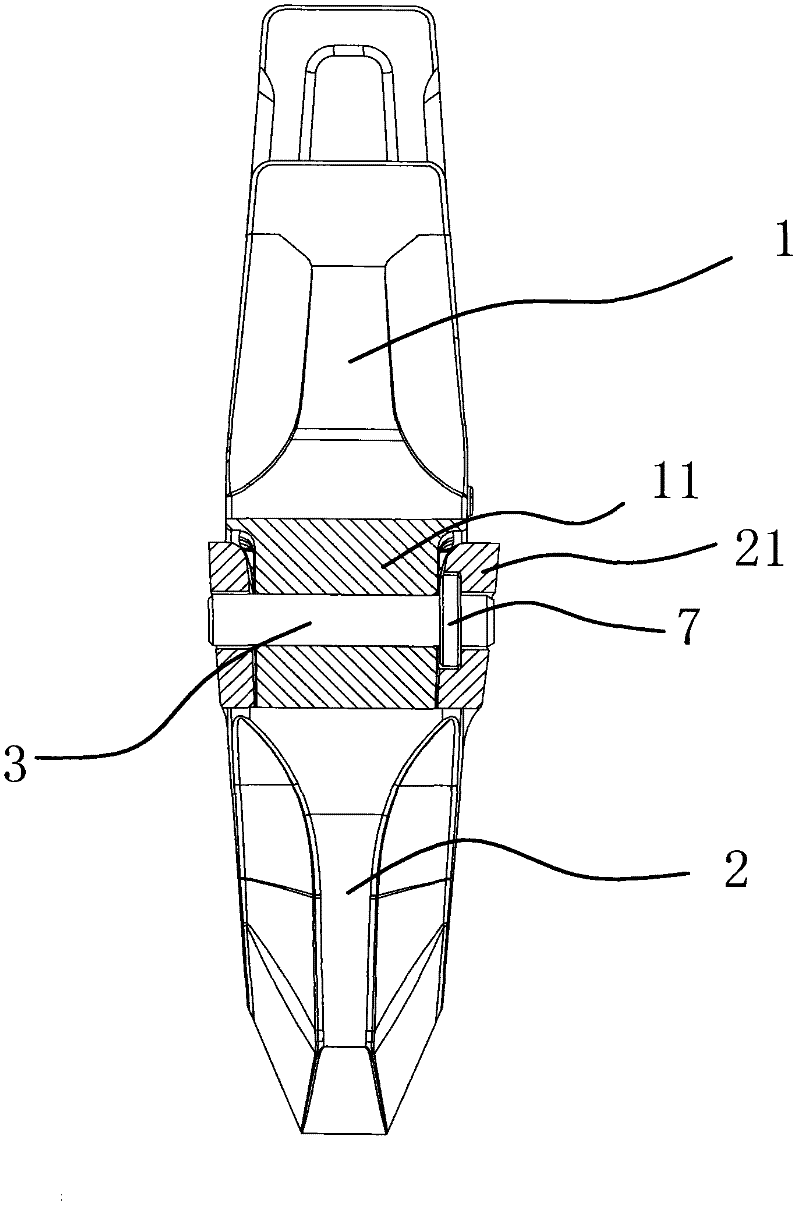

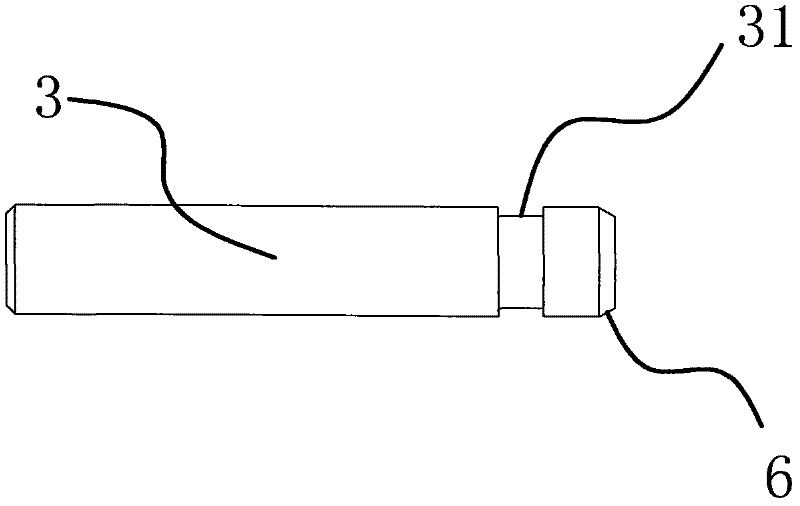

[0030] Such as figure 1 and figure 2 As shown, the bucket tooth of the excavator includes a tooth holder 1 with a mounting part 11 and a bucket tooth 2 with a connecting part 21. The installation part 11 of the tooth holder 1 is inserted between the two connecting parts 21 of the bucket tooth 2 and passed through the pin 3 and circlip 4 are fixedly connected, such as Image 6 As shown, the jumper 4 is a spiral jumper 4, and when the jumper 4 is stretched by the pin 3, the jumper 4 is stretched as a whole, so that when the jumper 4 is closed, the inner surface of the jumper 4 and the pin 3 Closely adhering, so that the clip spring 4 can be firmly clamped on the pin 3, and there is no gap between the clip spring 4 and the pin 3.

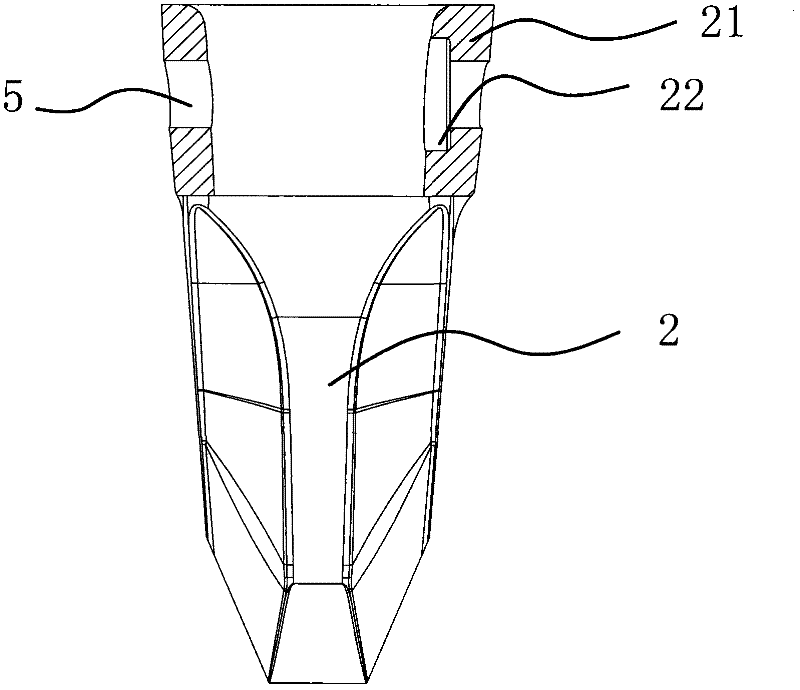

[0031] Such as Figure 3 to Figure 5As shown, an annular groove 31 is provided on the pin 3 and the circlip 4 is stuck in the annular groove 31, and a counterbore 22 is provided on the inner end surface of the pin hole 5 at either end of the bucket...

Embodiment 2

[0037] Such as Figure 7 to Figure 9 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference lies in that the inner end faces of the pin holes 5 on the two connecting parts 21 of the bucket teeth 2 are provided with counterbore holes 22, and the counterbore holes 22 are uniformly arranged in the counterbore holes 22. A snap ring 4 is installed, which makes the connection between the bucket tooth 2 and the tooth holder 1 more firm. On the inner side of one of the annular grooves 31 on the pin 3, a chamfer 6 is provided, through which the chamfer 6 can make when the first jumper 4 falls into the annular groove 31 provided with the chamfer 6 When continuing to beat the hammer, the jump ring 4 can be disengaged from the annular groove 31 so that the pin 3 can continue to move forward.

[0038] When installing, firstly install the two snap springs 4 in the fixing seat 7 and place them in the counterbore 22 of the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com