Charging method and device of straight-pull silicon single crystals

A technology of Czochralski silicon and charging, which is applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of easy contamination of polycrystalline silicon raw materials, poor safety of charging operation, and high labor intensity of charging, etc. Achieve the effect of improving production efficiency and utilization rate of crystal pulling furnace, reducing labor intensity and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

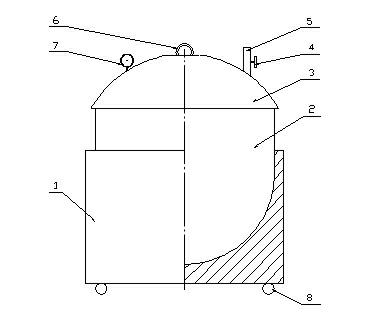

[0028] A kind of charging method of Czochralski silicon single crystal adopts such as figure 1 and figure 2 The device shown includes the steps of preparation before charging, charging, closing the lid and vacuuming, loading into the crystal pulling furnace, removing the lid of the quartz crucible and closing the furnace, specifically:

[0029] Step 1: Preparation before charging: move 100kg polysilicon material, a 22-inch quartz crucible 2, 23.4g master alloy, charging car 1 and air pump into the 100-class clean air shower room in sequence;

[0030] Step 2: Loading: While the operators are dismantling the furnace to clean the heat field, another group of operators wear clean clothes and enter the clean air shower room, unpack the quartz crucible 2, and put it on the charging cart 1 Then, according to the process requirements, all the polysilicon material and master alloy are loaded into the quartz crucible 2;

[0031] Step 3: Closing the lid and vacuuming: After wiping the...

Embodiment 2

[0035] A kind of charging method of Czochralski silicon single crystal adopts such as figure 1 and figure 2 The process of the shown device includes preparation before charging, charging, closing the cover and vacuuming, loading into the crystal pulling furnace, removing the cover of the quartz crucible and closing the furnace:

[0036] Step 1: Preparation before charging: move 150kg polysilicon material, a 24-inch quartz crucible 2, 35g master alloy, charging car 1 and air pump into the 100-class clean air shower room in sequence;

[0037] Step 2: Loading: While the operators are dismantling the furnace to clean the heat field, another group of operators wear clean clothes and enter the clean air shower room, unpack the quartz crucible 2, and put it on the charging cart 1 Then, according to the technological requirements, all the polysilicon material and the master alloy are loaded into the quartz crucible 2;

[0038] Step 3: Closing the lid and vacuuming: After wiping the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com