Method for producing an easily deformable flat steel product, flat steel product, and method for producing a component from such a flat steel product

A formability, flat steel technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as the impact of mechanical material properties, and achieve the effect of preventing material cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

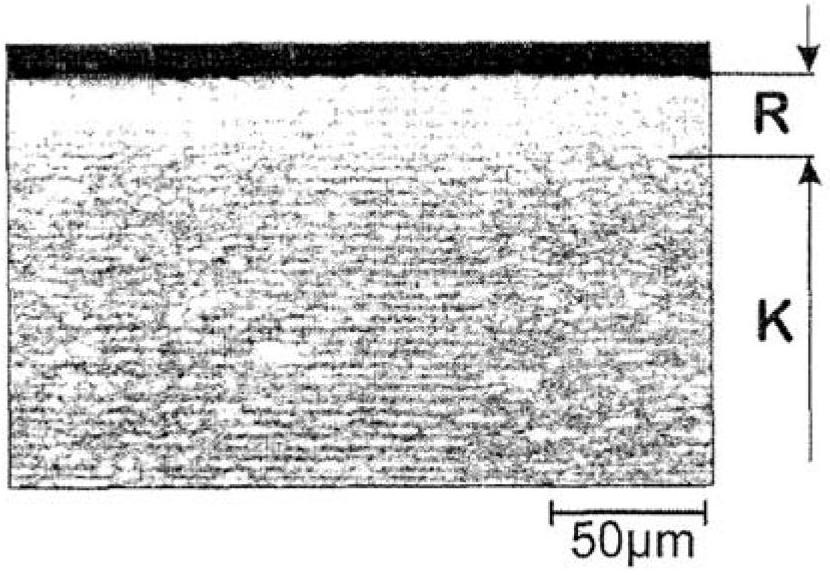

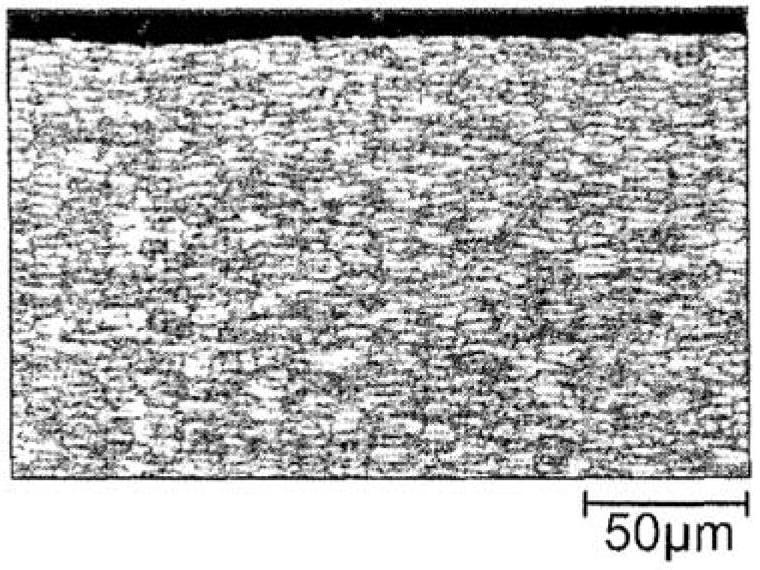

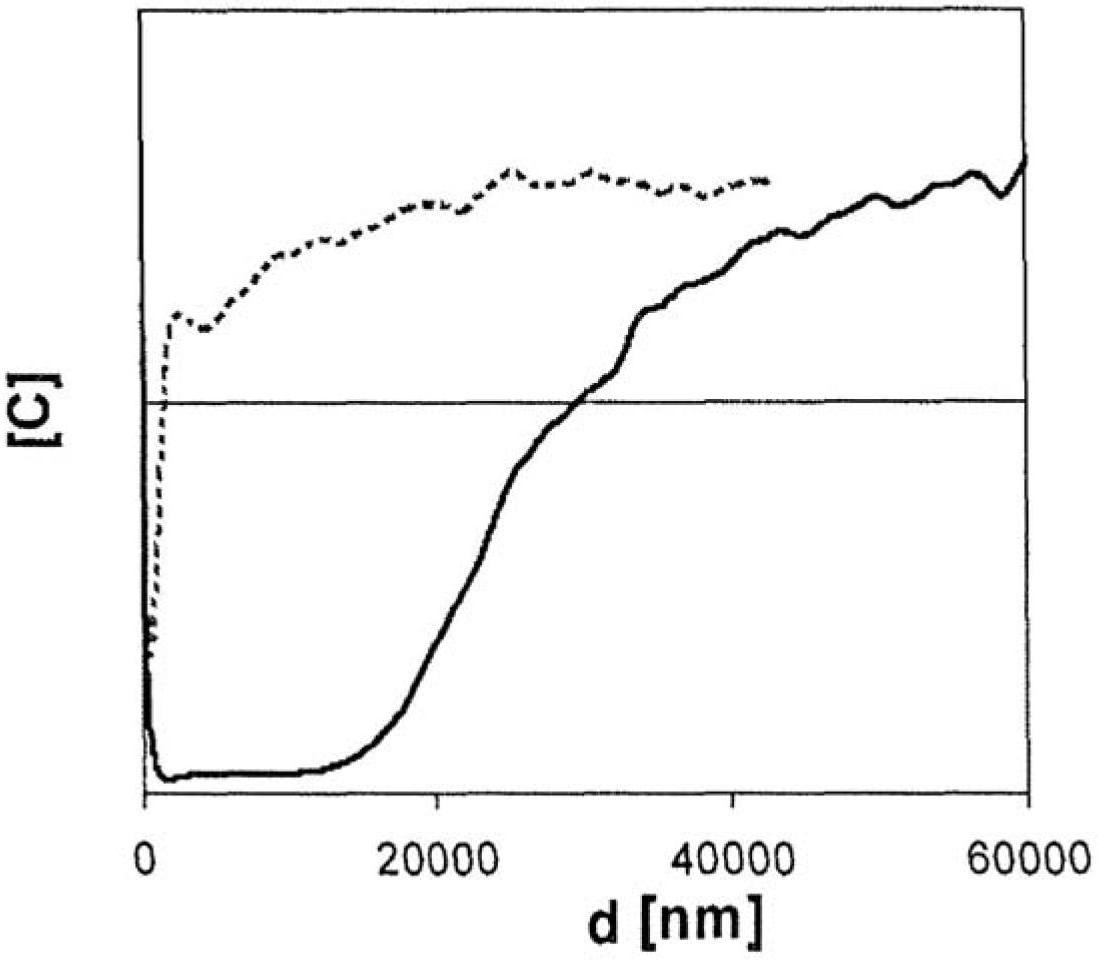

[0062] In order to examine the effect achieved by the method according to the invention, hard-rolled cold-rolled strip test pieces were used, each of the multiphase steel "MP" and of the steel "WU" usually used for hot forming. The compositions of steels MP and WU are given in Table 1.

[0063]

[0064] The rest of the iron and unavoidable impurities.

[0065] Table 1

[0066] Two test pieces each made of the steels MP and WU were annealed according to the invention in a through-flow furnace for edge layer decarburization. The annealing parameters used here are given in Table 2, column "Invention" below.

[0067] For comparison, two other test pieces made of steels MP and WU were conventionally annealed in a continuous furnace, by conventional annealing, which refers to the pretreatment usually performed for hot-dip galvanizing.

[0068] In order to optimize the mechanical properties of the test pieces, an overaging treatment was additionally carried out. This overaging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com