Liquid crystal display device and manufacturing method thereof

A technology of a liquid crystal display device and a manufacturing method, applied in nonlinear optics, instruments, optics, etc., can solve the problems of disturbing voltage response characteristics, deterioration and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0110] Embodiment 1 relates to a VA-mode liquid crystal display device (or liquid crystal display element) according to the first embodiment of the present invention and relates to a liquid crystal display device (or liquid crystal display element) according to the first embodiment or the third embodiment of the present invention. Manufacturing method. In Embodiment Mode 1, the first alignment film 22 is configured to contain one, two or more types of polymer compounds (first alignment-treated compounds) having crosslinked structures as side chains. Then, a pretilt is imparted on the liquid crystal molecules by a cross-linked or polymerized compound. Here, after forming the alignment film 22 containing one, two or more types of first polymer compounds (compounds before the first alignment treatment) containing main chains and side chains, after applying an electric field or a magnetic field, At the same time, the first alignment is generated by crosslinking or polymerizing th...

Embodiment approach 2

[0241] Embodiment 2 relates to the liquid crystal display device according to the second embodiment of the present invention, and relates to the manufacturing method of the liquid crystal display device according to the second embodiment and the third embodiment of the present invention.

[0242] In Embodiment 1, the compound after the first alignment treatment is obtained by crosslinking or polymerizing the crosslinkable functional group or the polymerizable functional group in the compound before the first alignment treatment containing a crosslinkable functional group or a polymerizable functional group as a side chain . On the other hand, in Embodiment 2, the compound after the first alignment treatment is obtained by deforming the compound before the first alignment treatment containing a photosensitive functional group as a side chain by irradiation with energy rays.

[0243] In addition, in Embodiment 2, the first alignment film 22 is also configured to contain one, two...

Embodiment 1

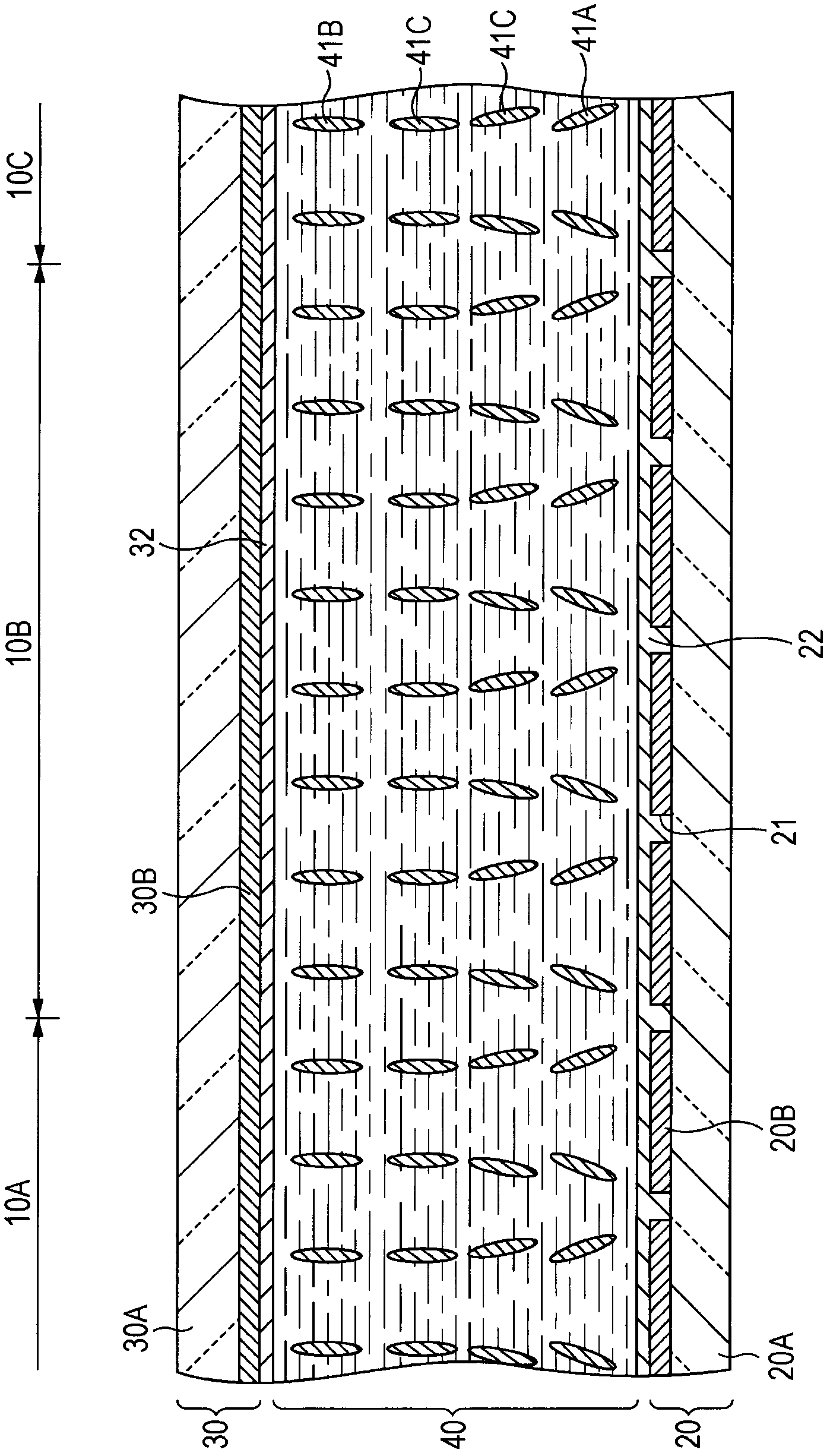

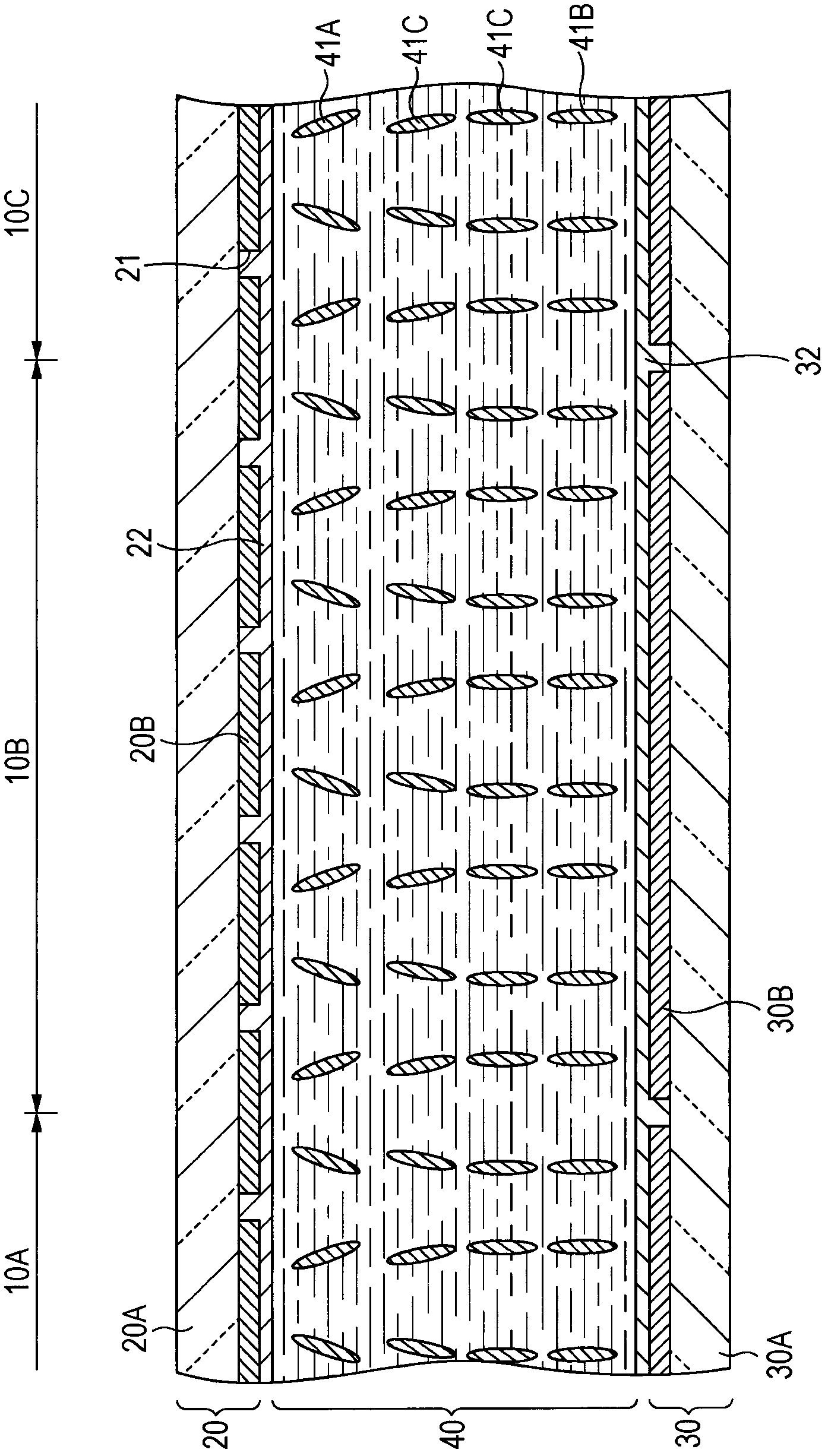

[0256] Example 1 relates to a liquid crystal display device (liquid crystal display element) and a manufacturing method thereof according to a first embodiment of the present invention and a liquid crystal display device (liquid crystal display element) and a manufacturing method thereof according to a third embodiment of the present invention. In Example 1, figure 1 The shown Embodiment 1 liquid crystal display device (liquid crystal display element) is manufactured through the following procedure.

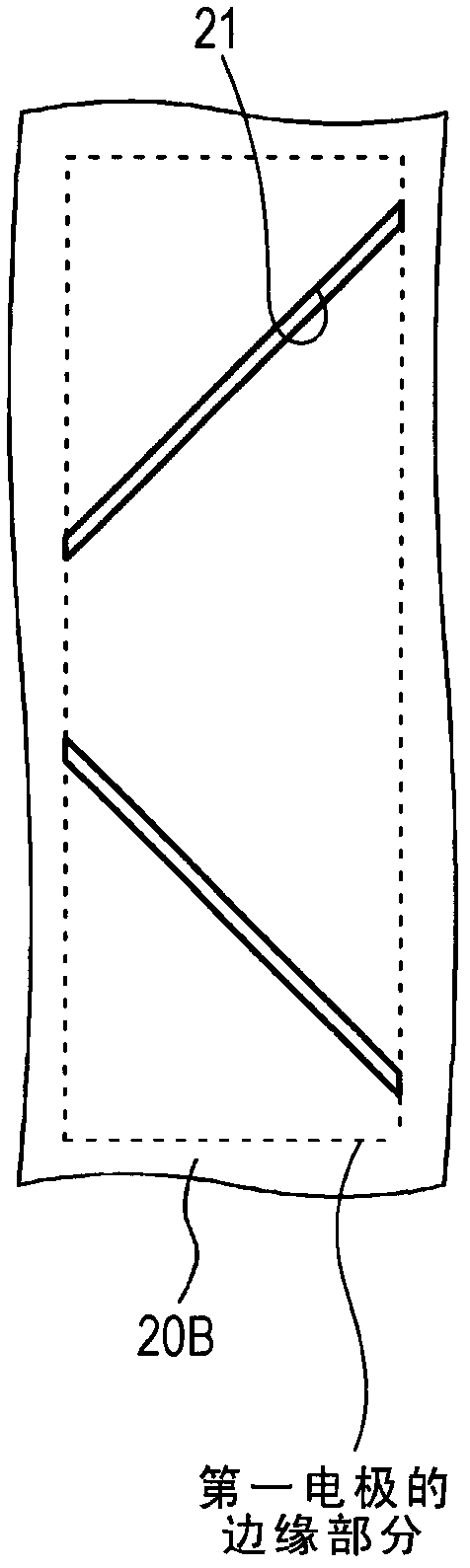

[0257] First, the TFT substrate 20 and the CF substrate 30 are prepared. On one side of a glass substrate 20A having a thickness of 0.7 mm, a first electrode having a slit pattern (the width and pitch of the first slit portions 21 are 5 μm and 65 μm, respectively, on which the first slit portions 21 are formed) is formed. The width of each part of 20B is 60 μm, and the interval between the first electrode 20B and the other first electrode 20B is 5 μm) and the base material of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com