Optical sensing detection device and method for fluid medium interface

An optical fiber sensing and fluid medium technology, applied in the field of instrumentation and optical fiber sensing, can solve the problems of the measured medium being easily corroded by salt water crystallization, unable to meet the long-term reliable operation, pollution, etc., to achieve high reliability and reduce system costs , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

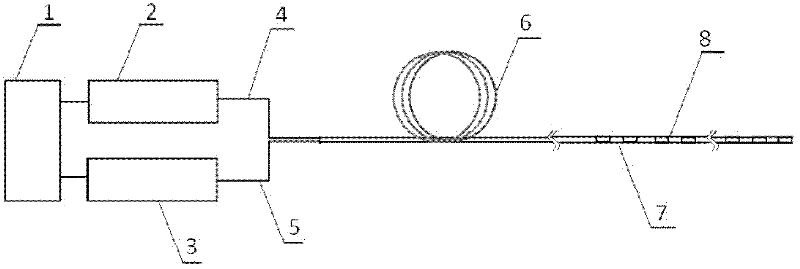

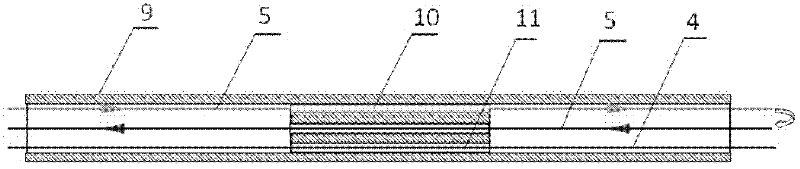

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0020] Under the control of the computer 1, the adjustable constant current power supply 3 provides heating current for the electric heating device 10 in the sensing basic unit 8 through the heating current transmission wire 5 in the stainless steel tube hard armor photoelectric composite cable 6 in the form of square wave output, and at the same time the optical fiber The sensor demodulator 2 continuously transmits the optical signal of wavelength scanning to the temperature measuring optical fiber 4, and receives the spectral signal reflected by the fiber Bragg grating temperature sensor 11 in the sensing basic unit 8, and calculates each The temperature value of the fiber Bragg grating temperature sensor 11. Since each fiber Bragg grating temperature sensor 11 has its own wavelength channel, by using wavelength division ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com