Sample position automatic adjusting device in product quality detecting system

An automatic adjustment device and detection system technology, applied in the direction of measuring device, test sample preparation, color/spectral characteristic measurement, etc., can solve the problems that samples cannot enter the market, sampling and testing samples are destructive and time-consuming, etc., to achieve Improve the accuracy of the experiment, easy to master, and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

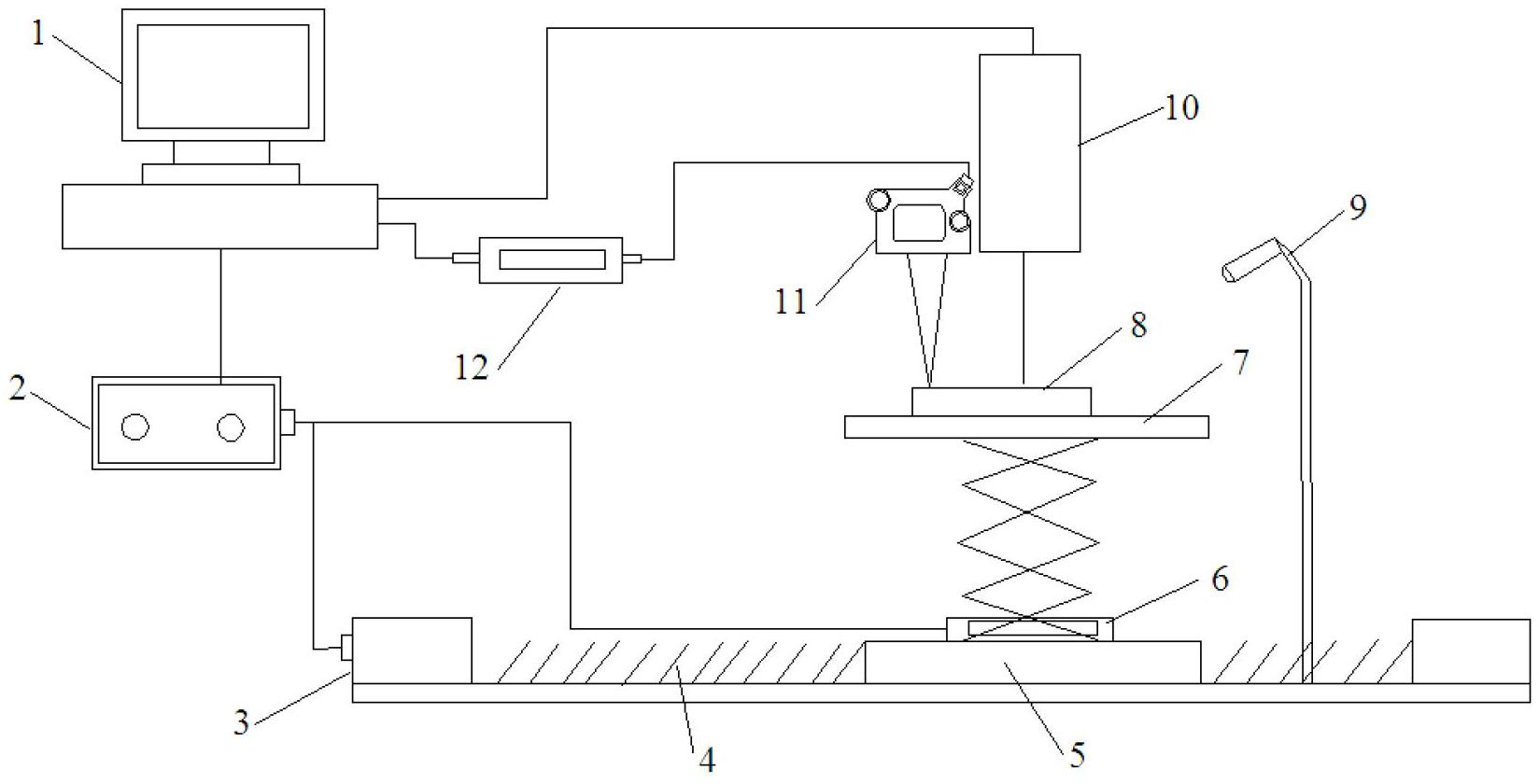

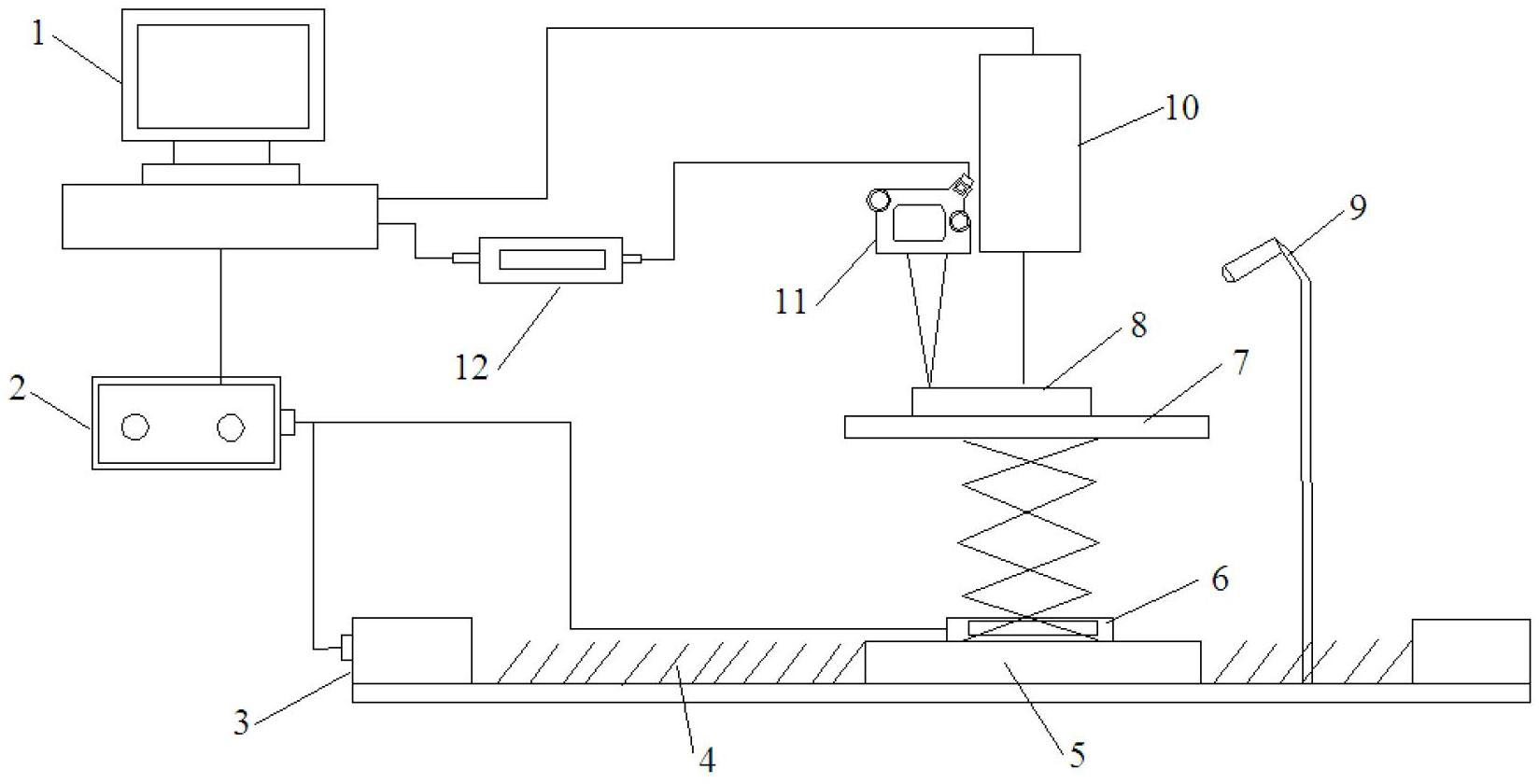

[0026] figure 1 Shown is the schematic structural diagram of the sample position automatic adjustment device in the product quality inspection system of this embodiment. Referring to the diagram, it mainly includes the following parts: the stage 7, on which the sample 8 is placed; the sample positioning unit, which is arranged on the carrier The top of the object table 7 is used to detect whether the sample 8 is located at a specified position; the sample position adjustment unit is connected to the object table 7 and used to adjust the height and horizontal position of the object table 7 to make the sample 8 reach a specified position. figure 1 The spectrometer 10 positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com