Double-control device and method for low waterhead Kaplan turbine

A technology of dual regulation and water turbine, applied in safety devices, mechanical equipment, hydroelectric power generation, etc., can solve the problems of unit flow reduction, unit stability reduction, guide vane opening reduction, etc., to increase braking torque and improve Stability and time-shortening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

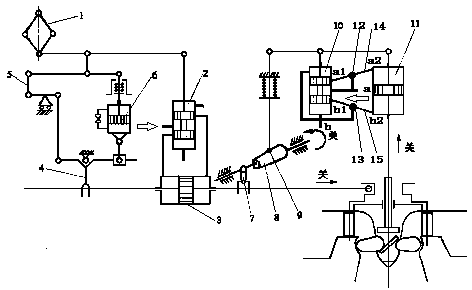

[0015] Such as figure 1 As shown, the first three-way valve 12 is connected to the first oil pipe 14 between the vane pressure distribution valve 10 and the vane servomotor 11, and the second oil pipe 15 between the vane pressure distribution valve 10 and the vane servomotor 11 is connected to The second three-way valve 13.

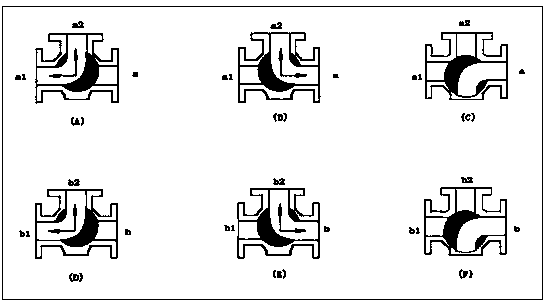

[0016] The a1 end of the vane pressure distribution valve 10 is connected to the first port of the first three-way valve 12, the a2 end of the vane servomotor 11 is connected to the second port of the first three-way valve 12, and the a end of the vane pressure distribution valve 10 is connected to the first port of the first three-way valve 12. The third way of the three-way valve 12.

[0017] The b1 end of the vane pressure distribution valve 10 is connected to the first port of the second three-way valve 13, the b2 end of the vane servomotor 11 is connected to the second port of the second three-way valve 13, and the b end of the vane pressure distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com