Nozzle surface cleaning device and ink-jet recording device

A cleaning device and inkjet recording technology, which is applied in the field of head cleaning, can solve the problems of long time for wiping parts to be wet, damage of lyophobic film, inability to solve cleaning liquid uniformity, cleaning liquid liquid dripping, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0030] (Apparatus Configuration of Inkjet Recording Apparatus)

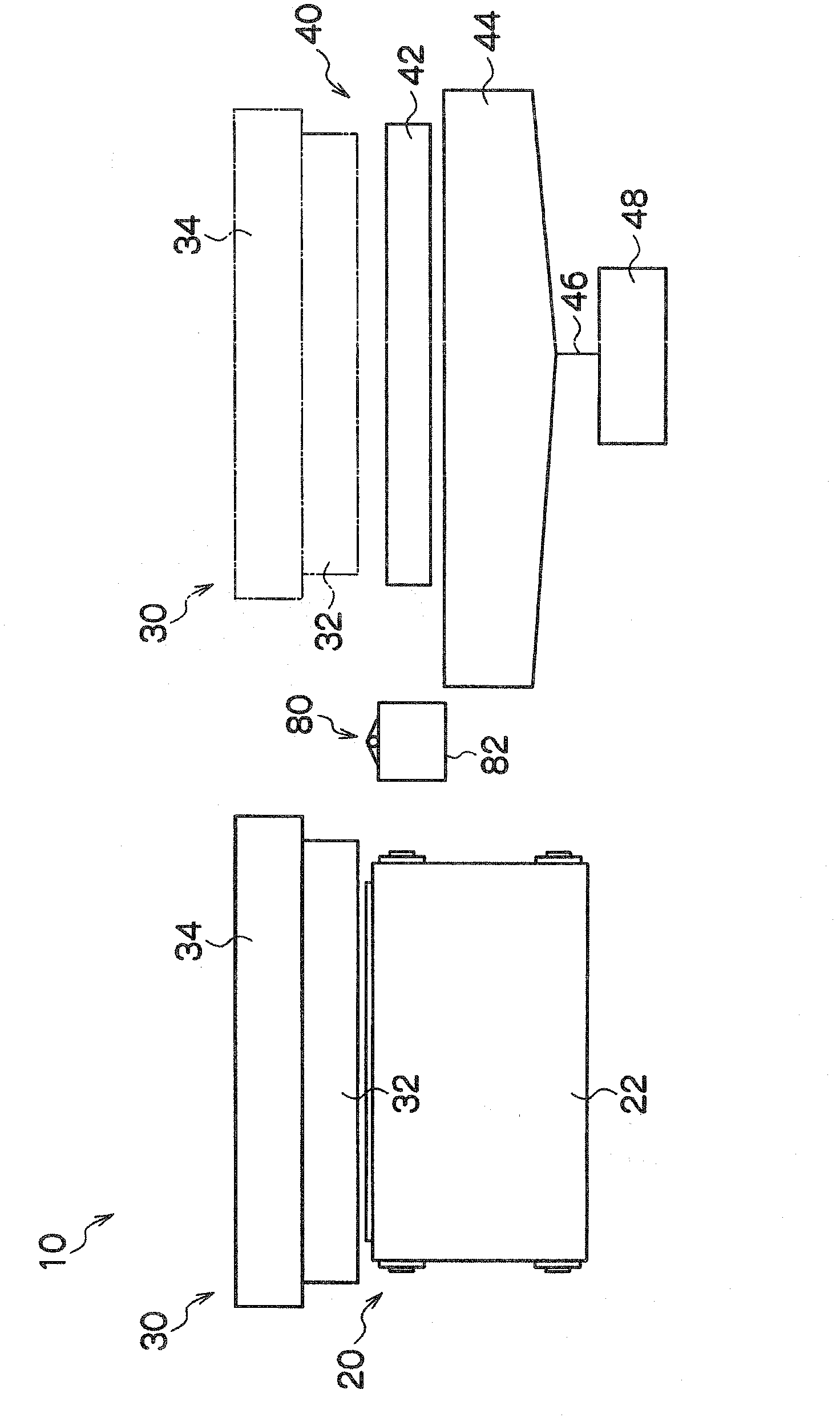

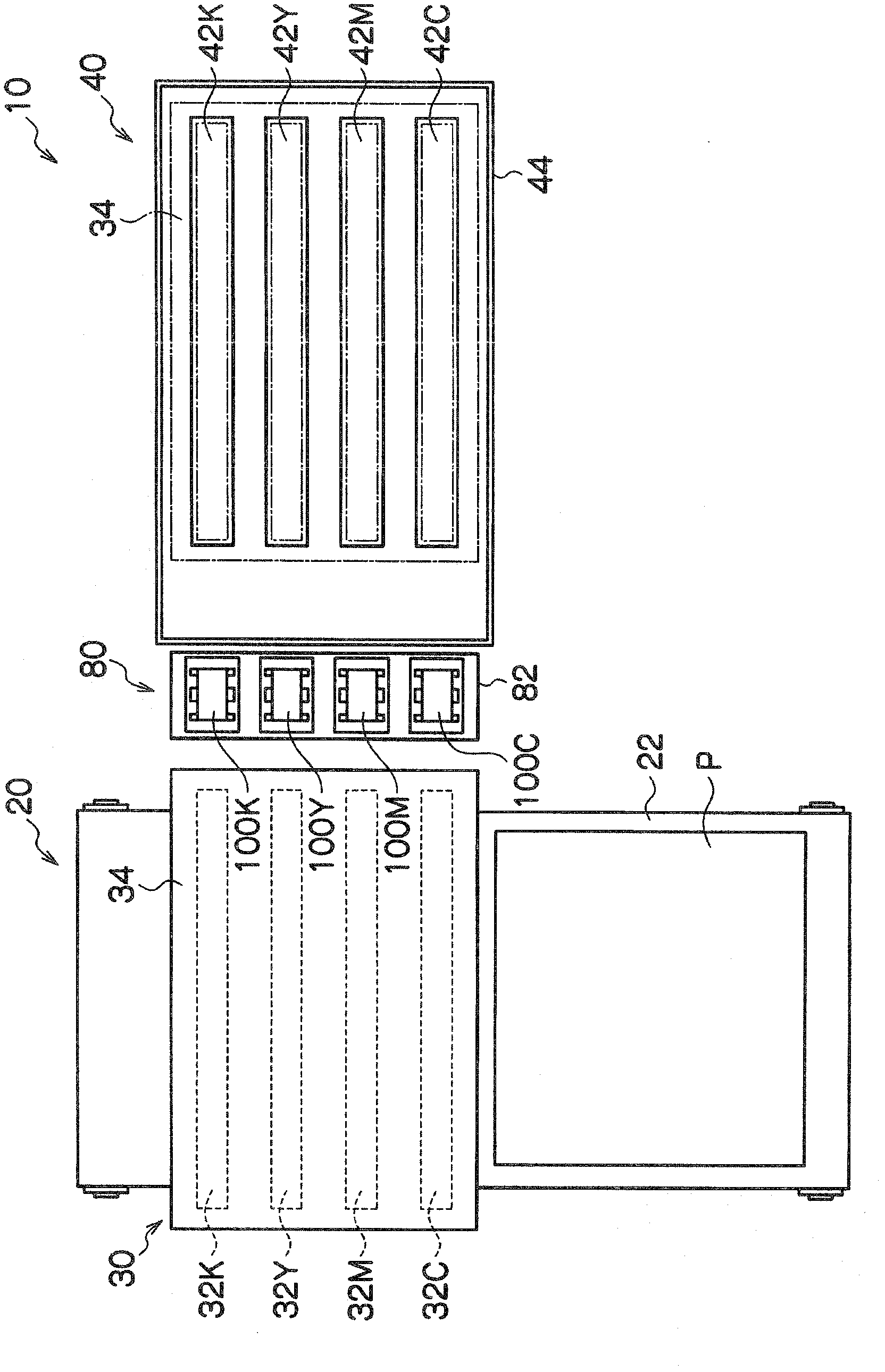

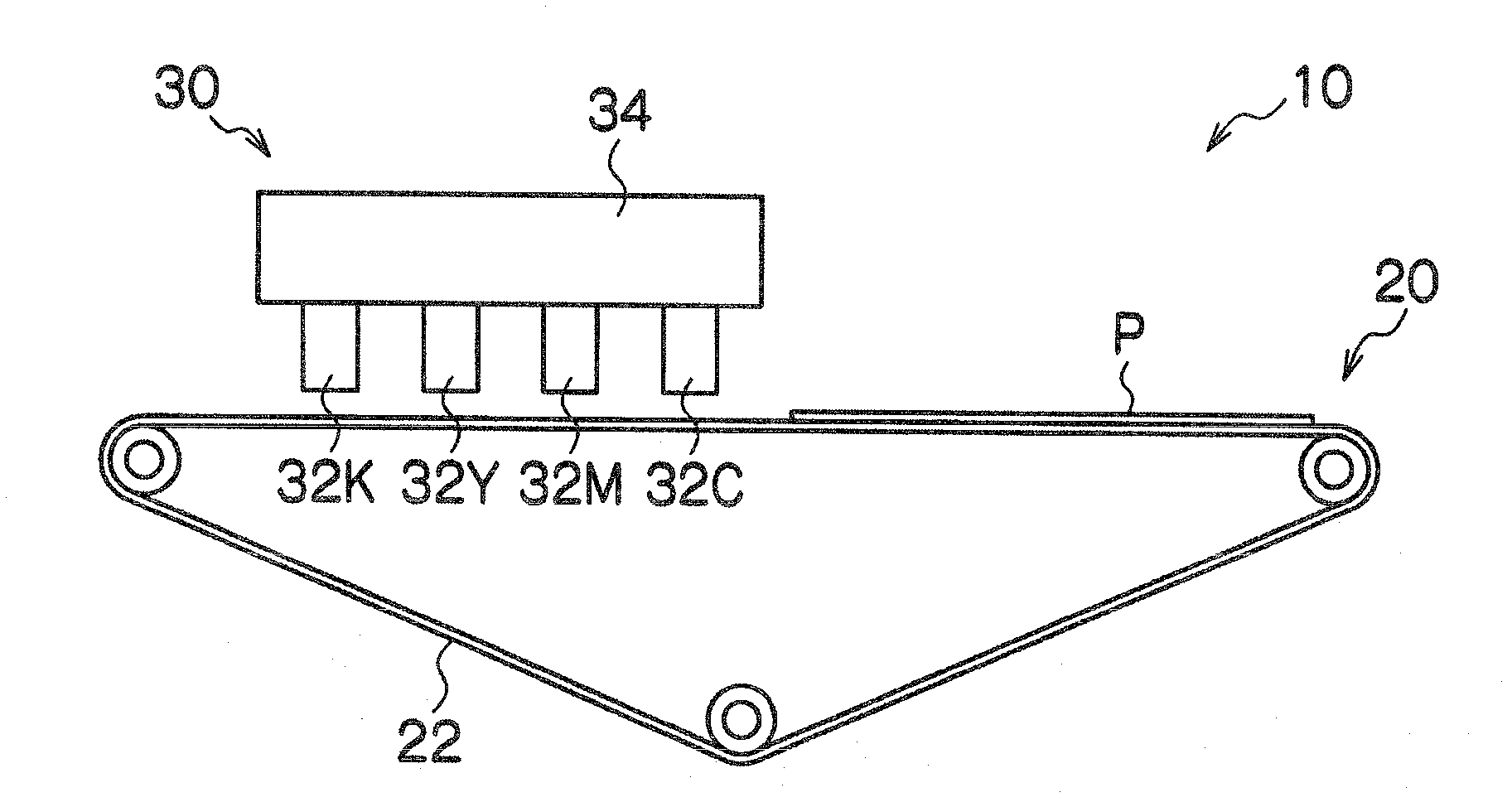

[0031] Figure 1 ~ Figure 3 It is a front view, a plan view, and a side view showing the configuration of main parts of the inkjet recording apparatus according to this embodiment.

[0032] as it should Figure 1~3 As shown, the inkjet recording device 10 is a single-pass type line printing machine, and mainly ejects to the paper P conveyed by the paper conveying mechanism 20 by a paper conveying mechanism 20 that conveys a recording medium, that is, a paper (sheet) P. The head unit 30 for cyan (C), magenta (M), yellow (Y), and black (K) ink droplets of each color, the maintenance unit 40 for performing maintenance of each head mounted on the head unit 30 , and the cleaning unit 40 mounted on the The nozzle surface cleaning device 80 of the nozzle surface of each head of the head unit 30 is comprised.

[0033] The paper conveying mechanism 20 is constituted by a belt conveying mechanism, and makes the moving b...

no. 2 approach

[0108] Next, a second embodiment of the present invention will be described. In addition, in the following description, description of the same configuration as that of the above-mentioned first embodiment will be omitted. In the first embodiment, the remaining cleaning solution for wiping the web is recovered by suction with the recovery pump, but in the second embodiment, the remaining cleaning solution for wiping the web is recovered by pressing with the squeezing mechanism .

[0109] Figure 6 It is a schematic diagram which shows the schematic structure of the wiping off unit 100 of this embodiment. as it should Figure 6 As shown, the cleaning liquid recovery part 150 of the wiping unit 100 is provided with a pair of squeeze rollers 170 and a push adjustment roller instead of the recovery roller 152, the third guide roller 154, and the fourth guide roller 156 of the cleaning liquid recovery part 150 of the first embodiment. Mechanism 172 and recovery receiving part 1...

no. 3 approach

[0118] Next, a third embodiment of the present invention will be described. In addition, in the following description, the description of the same configuration as the above-mentioned embodiment is omitted. In this embodiment, the remaining cleaning liquid is recovered by evaporating using the air blowing mechanism and the temperature raising mechanism.

[0119] Figure 7 It is a schematic diagram which shows the schematic structure of the wiping off unit 100 of this embodiment. as it should Figure 7 As shown, the cleaning liquid recovery unit 150 of the wiping unit 100 includes a blower fan 180 (air blower mechanism), a suction fan 182, and a heating plate 184 (heating mechanism).

[0120] The blower fan 180 is a blower mechanism for evaporating the washing liquid applied to the wiping roll paper 112 . The blower fan 180 is configured to have a width corresponding to the width of the wiping paper roll 112, is arranged above the wiping paper roll 112, and can blow air dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com