Method for functionally checking a vacuum switch of a traction inverter

A technology for traction converters and vacuum switches, which is applied in circuit breaker testing, high-voltage/high-current switches, electric switches, etc. It can solve problems such as complexity, damage to vacuum switches, and occupying the downtime of traction drive devices, so as to simplify faults The detection method is simple and easy, and the effect of fault detection is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

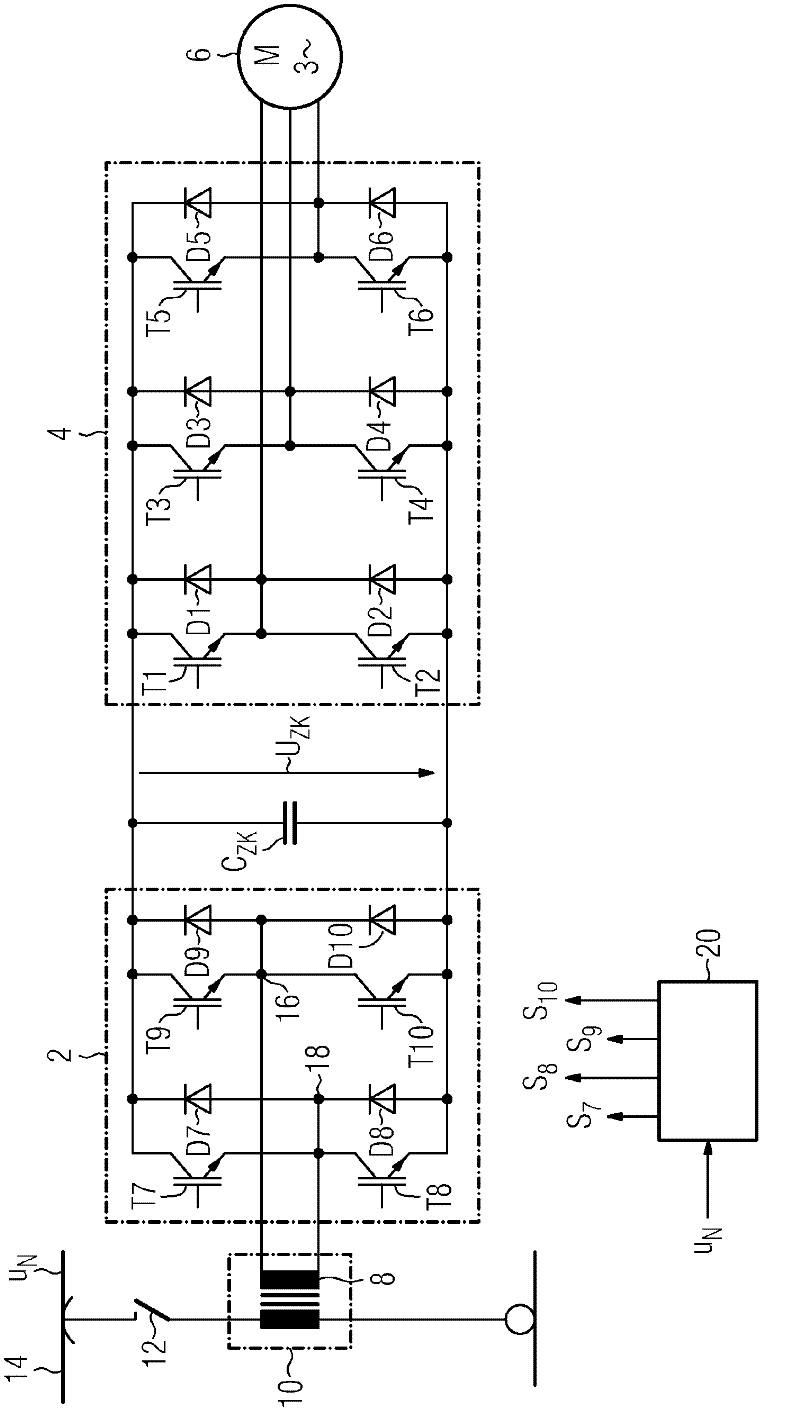

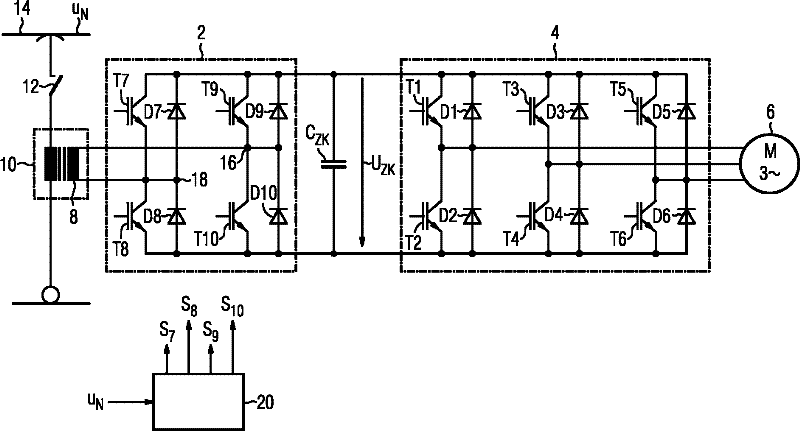

[0016] The invention and the principle of operation of the method according to the invention will be described in detail below with the aid of the drawings.

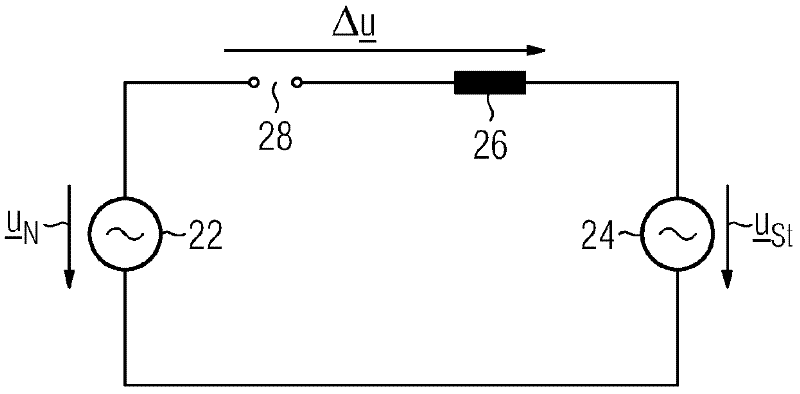

[0017] This single-phase equivalent circuit diagram has a voltage source 22 and a voltage source 24 connected in parallel. A voltage source 22 replaces the grid, a voltage source 24 replaces the DC voltage side with an intermediate circuit capacitor C ZK The four-quadrant chopper 2. This single-phase equivalent circuit diagram only shows the leakage inductance 26 of the traction transformer 10 . An open vacuum switch 12 is shown in the equivalent circuit diagram as a spark gap 28 . The vacuum switch 12 is closed during operation of the traction converter, and the two voltage sources 22 and 24 are electrically connected in parallel via the leakage inductance of the traction transformer 10 . As shown in the equivalent circuit diagram, the grid AC voltage u N with chopper input voltage u St are phase shifted relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com