Array substrate and manufacturing method thereof

A technology of an array substrate and a manufacturing method, applied in the field of display, capable of solving the problems of complex structure of the array substrate, inability to further increase the effective pixel area, and poor stability, and achieve the effects of simplifying circuit routing, improving structural stability, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

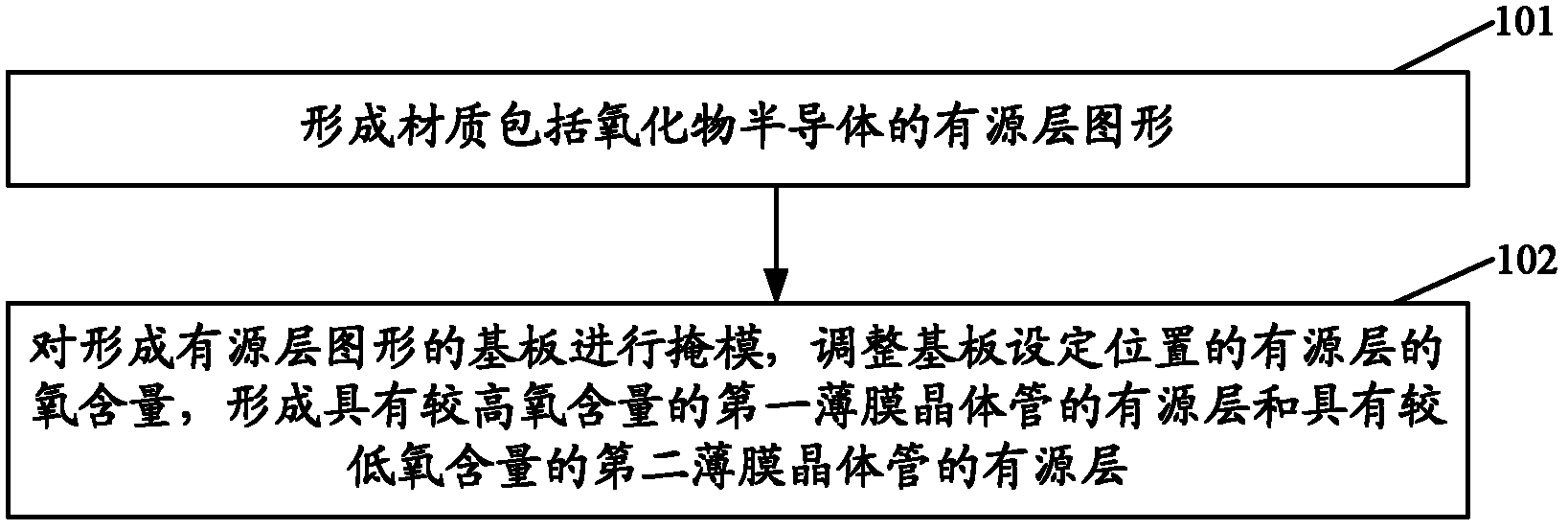

[0031] In order to solve the problem that IGZO semiconductor is used as the channel material of the active layer of the array substrate in the prior art, only its depletion or enhancement characteristics can only be used. The structure of the array substrate is relatively complicated, the stability is poor, and the effective pixel area cannot To further increase the technical problem, the present invention provides an array substrate and a manufacturing method thereof.

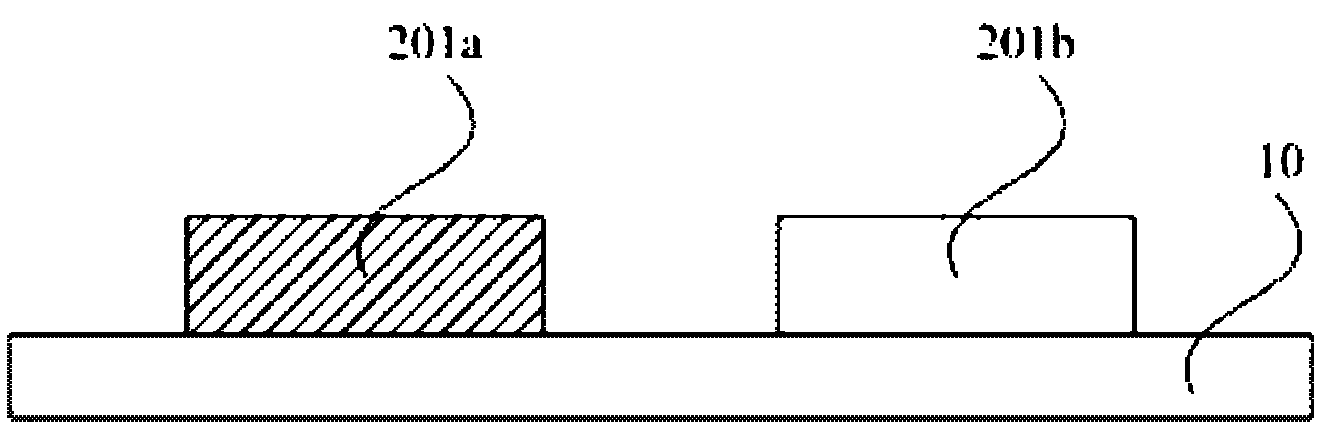

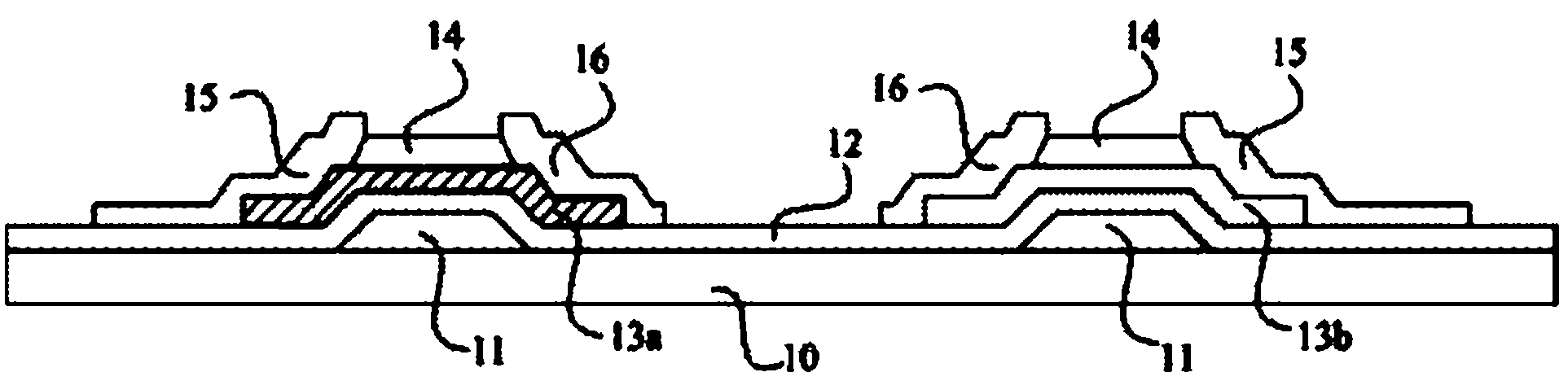

[0032] like figure 1 As shown, the array substrate of the present invention includes: a substrate 10 and a first thin film transistor 201a and a second thin film transistor 201b respectively located on the substrate 10, wherein the first thin film transistor 201a is an enhancement type, and the second thin film transistor 201b is depletion type.

[0033] The material of the active layer of the first thin film transistor 201a and the active layer of the second thin film transistor 201b includes an oxide semico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com