Automatic pressure filter device

A filtering device and automatic pressurization technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of easy overturning, damage to experimenters, low efficiency, etc., to reduce damage to physical health, high work efficiency, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

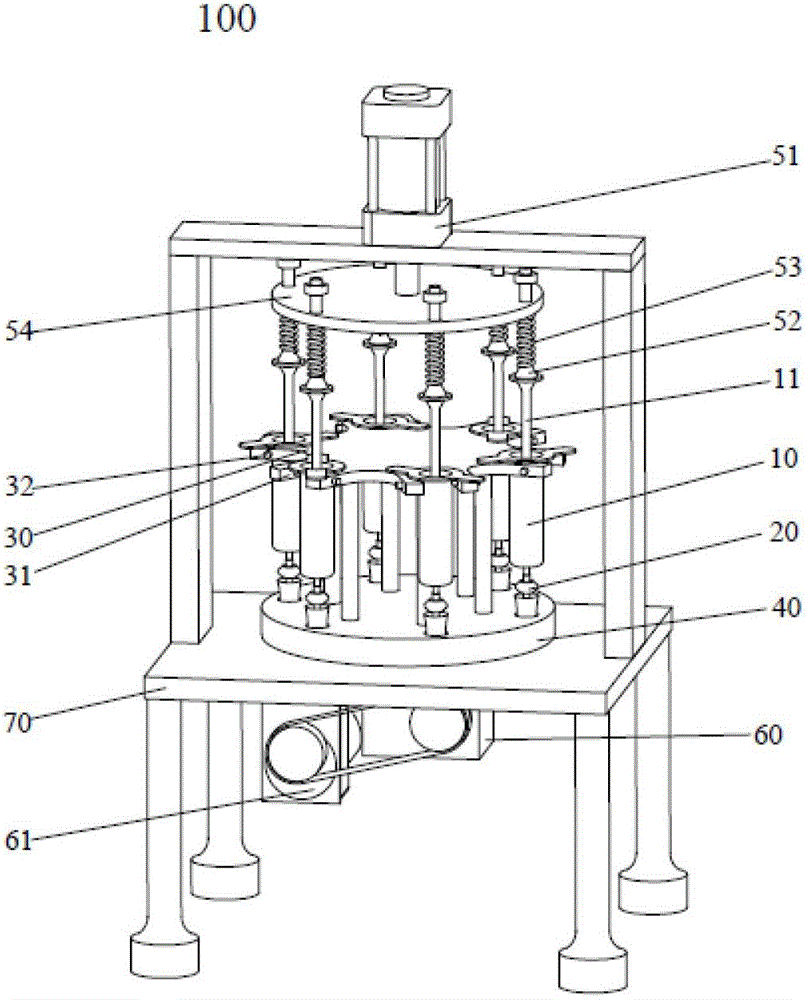

[0018] Below in conjunction with accompanying drawing, the present invention is further described: the present invention provides a kind of can filter many sample solutions at the same time, filter saves time and effort, the automatic pressure filtration device 100 of high efficiency, the labor intensity that exists when filtering sample solution is big, time Long technical question. The technical scheme adopted in the present invention is:

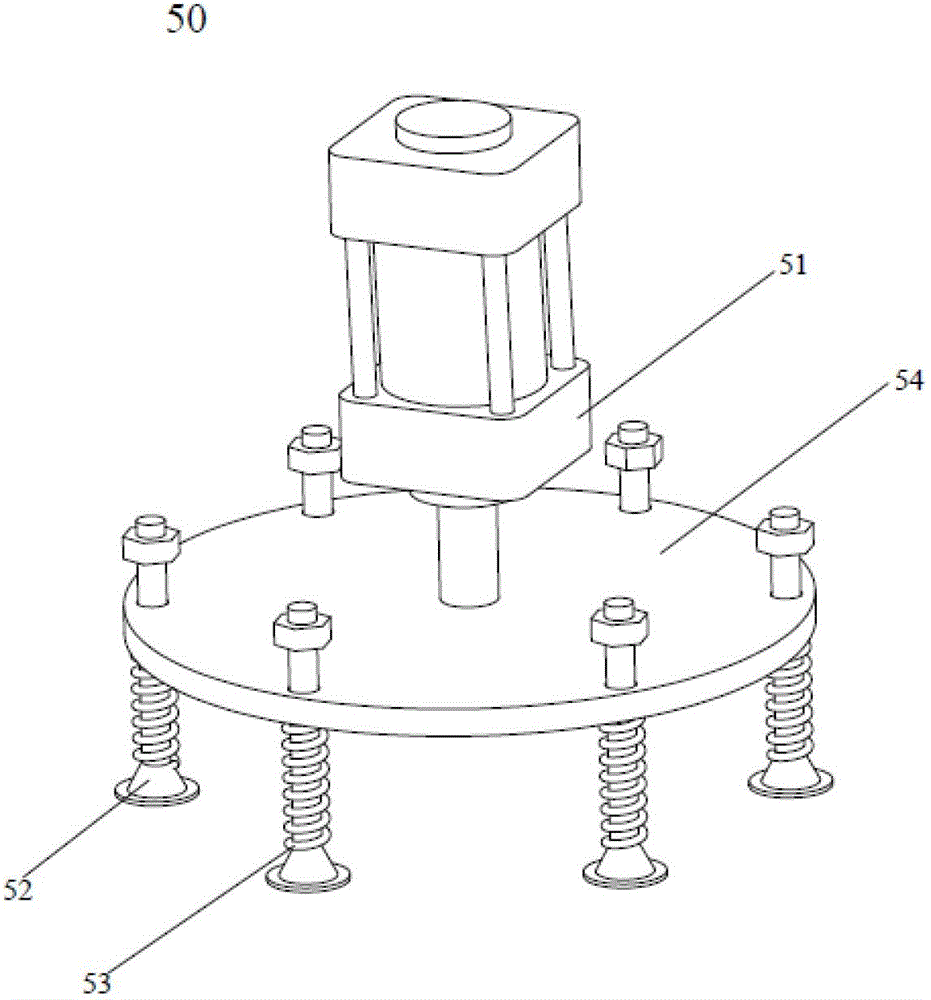

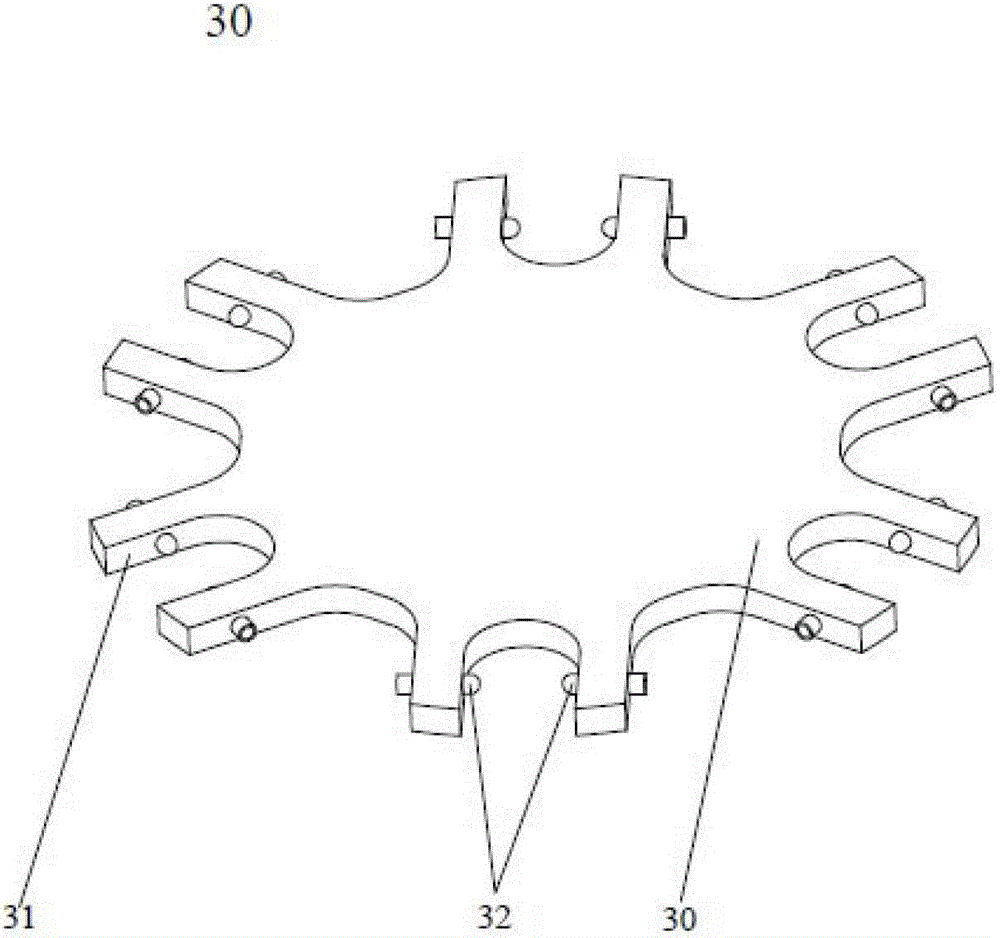

[0019] An automatic pressure filtration device 100, comprising a syringe 10 pre-installed with the solution to be filtered, a filter 20 docked with the syringe 10, a syringe positioning slot plate 30, a bottle receiving plate 40, and an automatic pressurizing device 50 , the automatic pressurization device 50 is placed above the syringe positioning slot plate 30, and the automatic pressurization device 50 is provided with a plurality of pressing rods 52, which respectively pressurize a plurality of syringes 10, and pressurize the syringes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com