Connecting rod sliding shoe type flow distribution radial plunger pump

A radial column and sliding shoe technology, applied in the direction of variable displacement pump components, components of pumping devices for elastic fluids, pumps, etc. Pump leakage and other problems, to achieve the effect of improving work efficiency, sensitive and reliable oil control, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

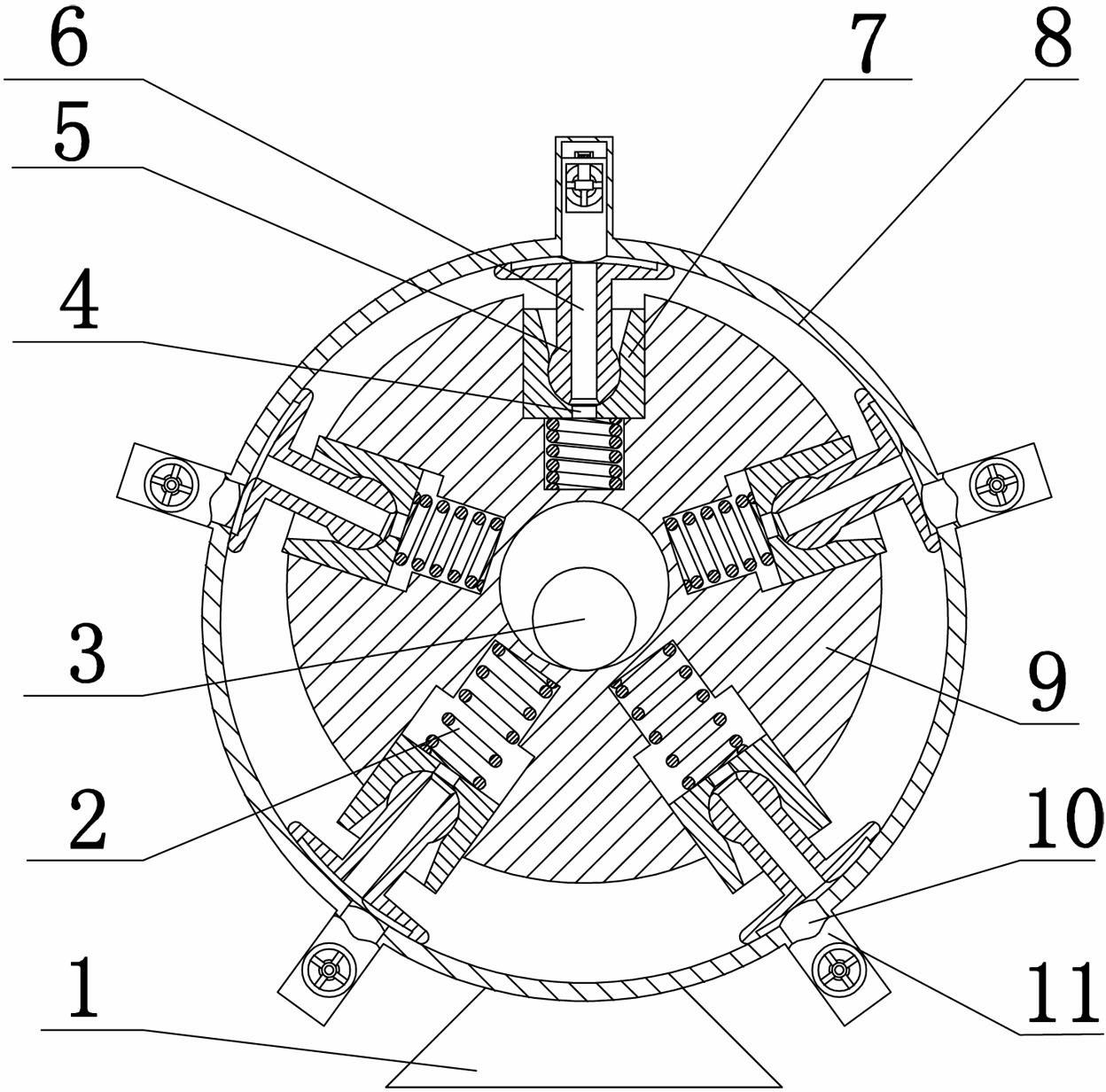

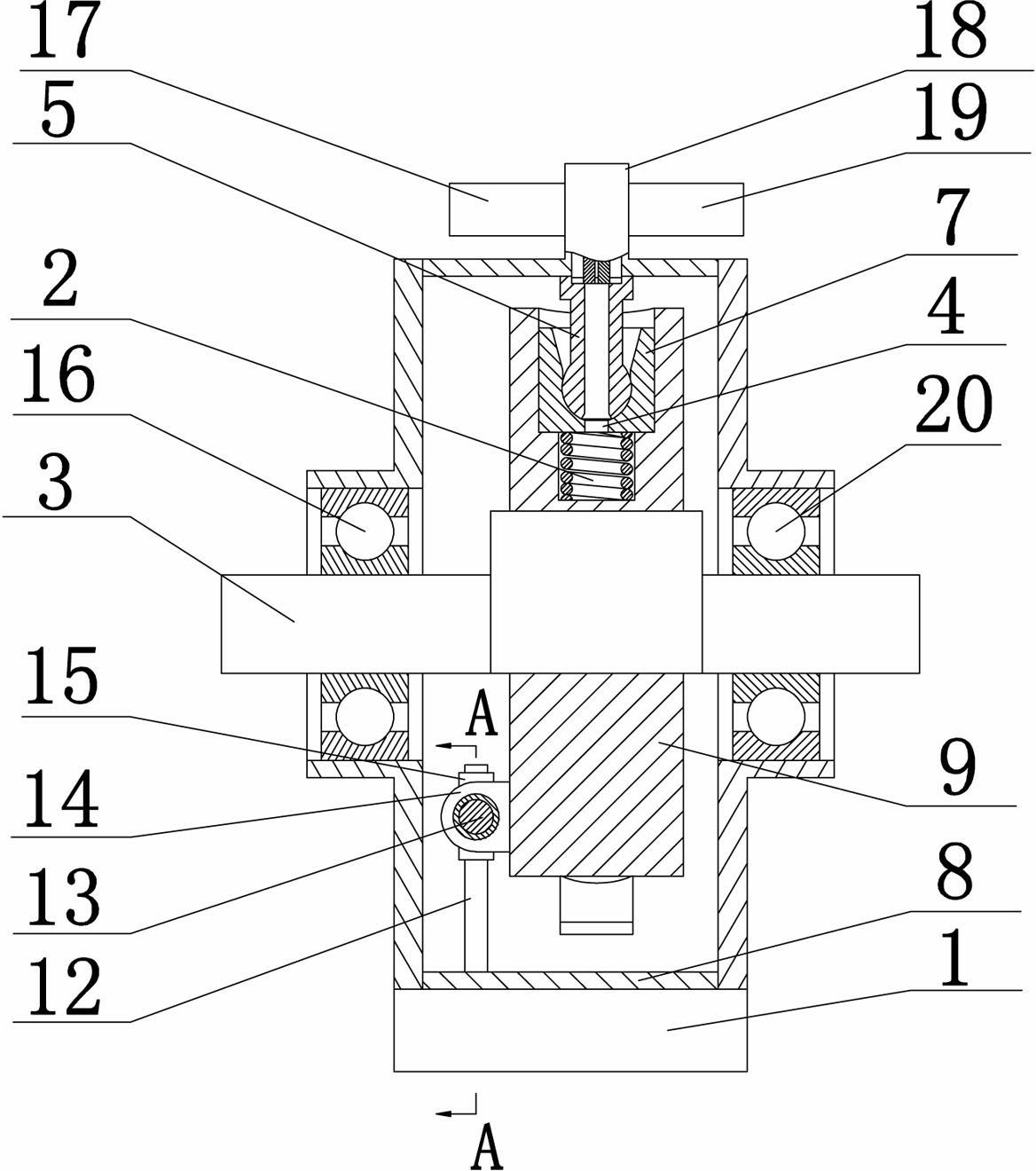

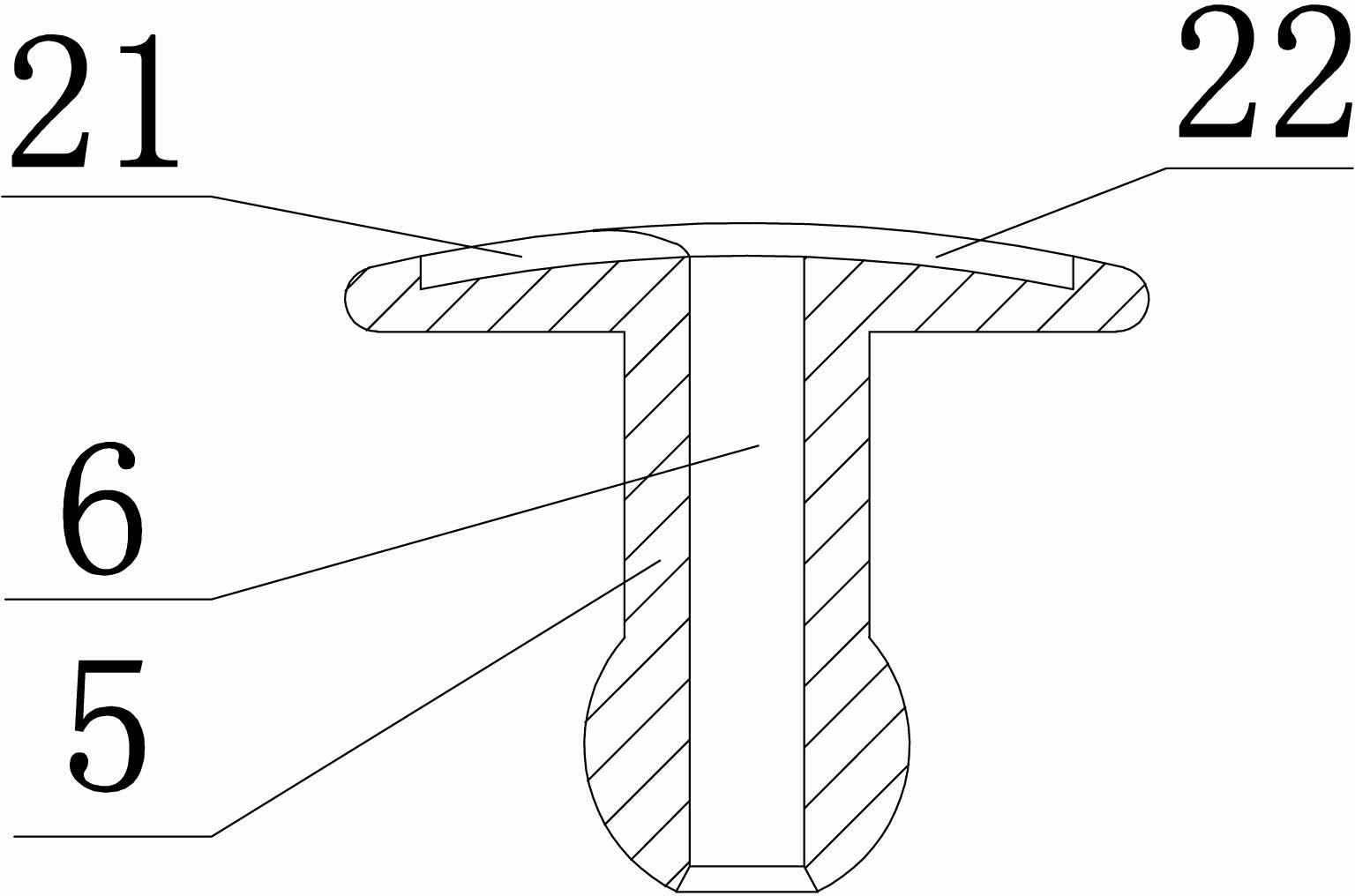

[0024] Such as figure 1 , 2 As shown, a connecting rod sliding shoe type flow distribution radial piston pump includes an eccentric shaft 3, a stator 8, a rotor 9, a set of plungers 7 with a central oil hole 4, a set of connecting rod sliding shoes 5, a The group oil control valve 11 is characterized in that the bottom of the stator 8 is fixedly connected with the base 1, the front and rear of the stator 8 are respectively provided with a front bearing assembly 20 and a rear bearing assembly 16, and the inner wall of the stator 8 A group of stator oil holes 10 are evenly distributed in the radial direction, and the group of stator oil holes 10 are connected to the group of oil control valves 11 correspondingly, and the eccentric shaft 3 is arranged in the stator 8 with two ends Connected with the front bearing assembly 20 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com