Edge-sealed and opened building heat-insulating vacuum insulated panel and manufacturing method thereof

A technology for vacuum thermal insulation panels and building thermal insulation, which is applied in thermal insulation, building components, insulation improvement and other directions, can solve problems such as affecting the indoor environment, water vapor can not be discharged, building walls and thermal insulation panels are mildewed, etc., to achieve high-efficiency thermal insulation, Avoid the effect of mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

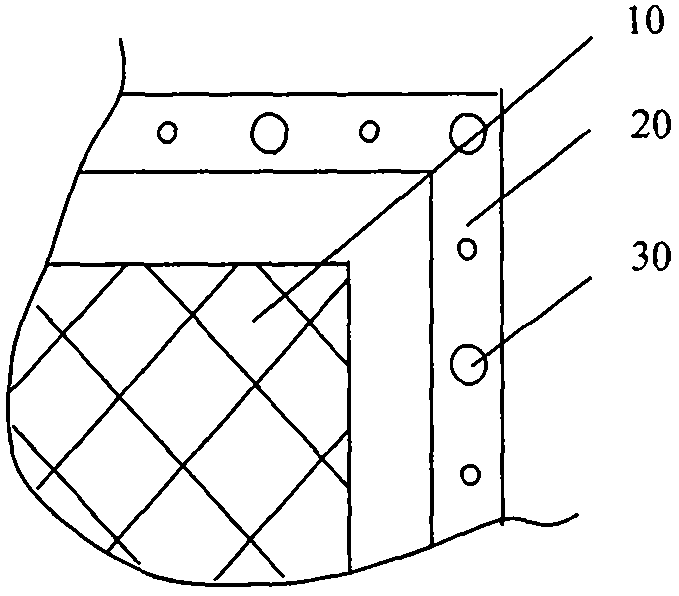

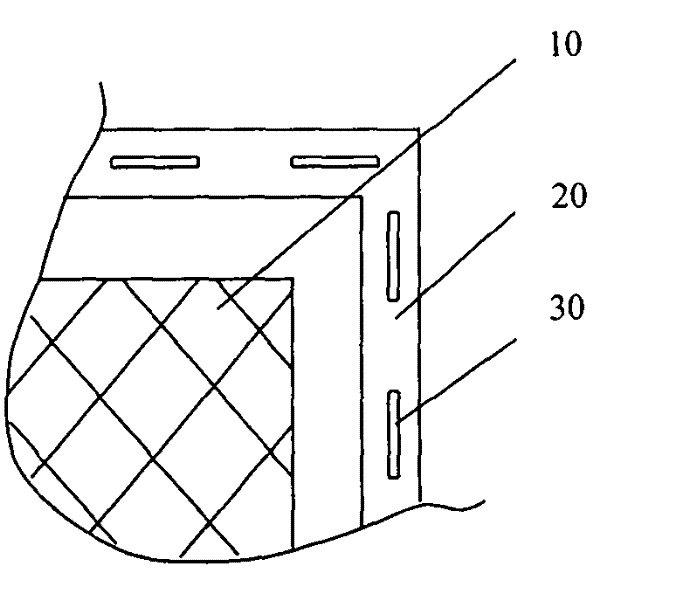

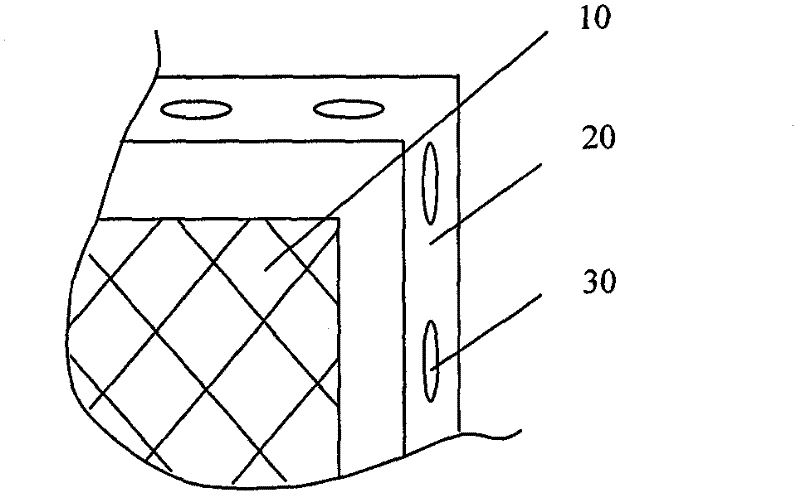

[0028] refer to image 3 , an edge-sealing oval opening vacuum insulation panel described in this embodiment includes: a core material 10 ; a barrier film 20 ; an oval opening 30 . The major semi-axis of the ellipse is 4mm, and the minor semi-axis is 1.5mm.

[0029] When the vacuum insulation panel is prepared, the specific process steps are as follows:

[0030] (1) In the production process of the vacuum insulation panel packaging bag, the three sides of the barrier film are sealed, and one side is used as a vacuuming port;

[0031] (2) Mechanical punching of elliptical holes is carried out in the middle of the heat-sealing edges on both sides of the barrier film, and the hole and the edge of the hole are separated by 80mm to form a vacuum insulation panel packaging bag with elliptical holes on the side heat-sealing edges;

[0032] (3) The core material is placed in a packaging bag, and the whole is put into a vacuum heat sealing machine to be evacuated, and the opening edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com