Holographic laser cold-turning gold stamping transfer coating composition and preparation method thereof

A technology for transferring paint and composition, applied in the field of holographic laser cold transfer bronzing transfer paint composition and preparation thereof, can solve the problems of complex resin system, poor process operability, difficult product quality control, etc., and achieve advanced technology. excellent transfer performance, good printing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation of the holographic laser cold transfer bronzing transfer coating composition of the present embodiment comprises the following steps:

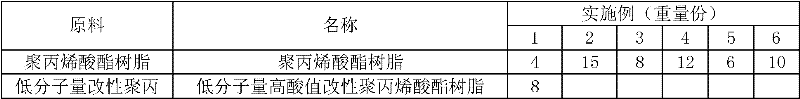

[0052] (1) Prepare raw materials according to the components and parts by weight shown in Table 1:

[0053] (2) first place the solvent in the reaction kettle, open the stirring device, and mix evenly;

[0054] (3) Put the resin components (polyacrylate resin, low molecular weight modified polyacrylate resin and cellulose ester resin) into the reactor, control the stirring rate to 100rpm, and stir for 1h to fully dissolve the resin components;

[0055] (4) After the resin component is completely dissolved, put the additives into the reaction kettle, control the stirring rate to 150rpm, stir for 30min until the additives are fully dispersed and evenly, and filter to obtain the final product.

[0056] In this embodiment, the polyacrylate resin is a copolymer with a molecular weight of 50,000 to 90,000 polymerized from methy...

Embodiment 2

[0059] The preparation of the holographic laser cold transfer bronzing transfer coating composition of the present embodiment is the same as that of Example 1, the difference is that: in the step (3), the stirring rate is 200rpm, and the stirring time is 5h; in the step (4), the stirring rate is 100rpm , stirring time is 10min.

[0060] In this embodiment, the polyacrylate resin is a homopolymer with a molecular weight of 90,000 to 130,000 polymerized from methyl methacrylate and butyl methacrylate monomers; the low molecular weight modified polyacrylate resin It is an acrylic resin amine methacrylate with a molecular weight of 0.3-0.5 million; the molecular weight of the cellulose ester resin is 28,000-40,000.

[0061] In Example 2, because the functional coating contains functional acrylic resin amine methacrylate, while ensuring transfer and trimming performance, it has excellent adhesion fastness to vacuum aluminum plating, higher molding brightness and better laser effect...

Embodiment 3

[0063] The preparation of the holographic laser cold transfer bronzing transfer coating composition of the present embodiment is the same as that of Example 1, the difference is that the stirring speed is 150rpm in the step (3), and the stirring time is 3h; the stirring speed in the step (4) is 120rpm , stirring time is 20min.

[0064] In this embodiment, the polyacrylate resin is a copolymer with a molecular weight of 130,000 to 180,000 polymerized from methyl methacrylate, methyl acrylate, ethyl acrylate, and butyl acrylate; The non-toxic polyacrylate resin is a copolymer with a molecular weight of 0.5-0.7 million, which is formed by polymerizing hydroxypropyl acrylate and acrylic resin monomers; the molecular weight of the cellulose ester resin is 40,000-48,000.

[0065] In Example 3, because the molecular weight of the main resin is relatively high, the functional coating in Example 3 ensures good trimming performance as a whole after being combined with low molecular weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com