Magnesium phosphate cement grout material

A technology of magnesium phosphate cement and grouting material, which is applied in the field of building materials engineering, can solve the problems of large shrinkage of grouting material, loss of prestress, difficulty in normal hydration, etc., and achieves reduced project cost, fast early hardening, and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

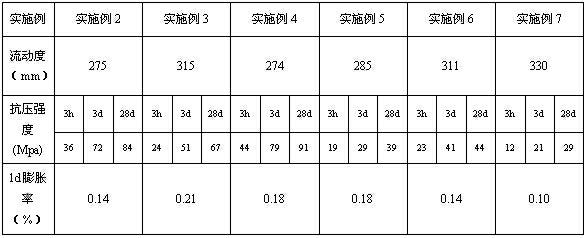

Examples

Embodiment 1

[0016] A magnesium phosphate cement grouting material is prepared from the following components in parts by weight: 100 parts of phosphate, 100-400 parts of metal oxide, 5-150 parts of fly ash, 5-150 parts of ground slag, and coagulation regulator 10-100 parts, water 26-300 parts; according to the above ratio, mix phosphate, metal oxide, fly ash, ground slag and coagulant evenly, then add water and stir evenly to obtain magnesium phosphate cement grouting material.

[0017] Among them, phosphate is an industrial product, and the mass percentage purity is not less than 96%. The metal oxide is perburned magnesium oxide, and its mass percent purity is not less than 88%. Fly ash is one or a mixture of Class I ash, Class II ash or high calcium ash. The finely ground slag is one or a mixture of grades S105, S95 or S75. The coagulant is borax, which is an industrial product, and its mass percentage purity is not less than 98%. Phosphate is one or a mixture of ammonium dihydrog...

Embodiment 2

[0019] A magnesium phosphate cement grouting material is prepared from the following components in parts by weight: 100 parts of sodium dihydrogen phosphate, whose mass percent purity is 98%; 400 parts of overburned magnesium oxide, whose mass percent purity is 90%; 5 parts of ash; 5 parts of S95 grade finely ground slag; 48 parts of borax with a mass percent purity of 98%; 65 parts of water, in parts by weight. Mix burnt magnesium oxide, sodium dihydrogen phosphate, borax, fly ash and finely ground slag evenly according to the above ratio, put them into a mixer, add water and stir thoroughly to obtain magnesium phosphate cement grouting material.

Embodiment 3

[0021] A magnesium phosphate cement grouting material is prepared from the following components in parts by weight: 50 parts of sodium dihydrogen phosphate, whose mass percent purity is 99%; 50 parts of calcium dihydrogen phosphate, whose mass percent purity is 99%; overburned magnesium oxide 200 parts, its mass percent purity is 92%; 150 parts of Class II fly ash, 10 parts of S95 grade finely ground slag; 40 parts of borax, its mass percent purity is 99%; 58.5 parts of water are prepared in parts by weight. Mix burnt magnesium oxide, sodium dihydrogen phosphate, calcium dihydrogen phosphate, borax, fly ash, and finely ground slag evenly according to the above ratio, put them into a mixer, add water and stir thoroughly to obtain magnesium phosphate cement grouting material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com