Special disc-shaped milling cutter for processing toothed welding fork

A welding fork and disc-shaped technology, which is applied in the direction of milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult realization and large demand, and achieve the goals of small product error, high manufacturing precision, and increased service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

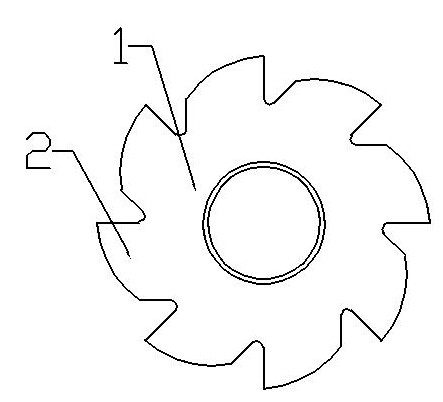

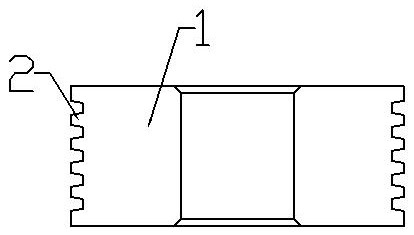

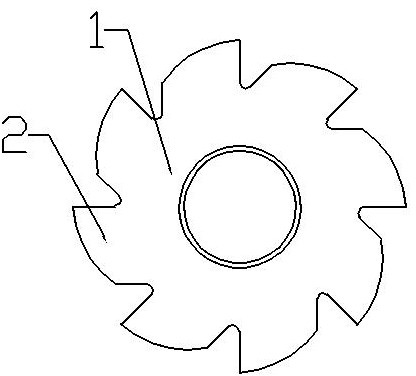

[0015] exist figure 1 , figure 2 The structure diagram of the special disc-shaped milling cutter for processing toothed welding forks shown in the figure, its main structure includes: cutter body 1, cutter teeth 2; eight cutter teeth 2 are evenly distributed on the outer edge of each circumferential surface of cutter body 1 .

[0016] The working principle of the present invention: the special disc tooth milling cutter has a cylindrical structure, the outer diameter is in accordance with the various tooth shapes required by the product, and the special tooth shape is processed into eight equal parts. Shape processing, so various four convex planes can be processed in one direction, and various tooth types can be milled on the four convex planes to increase the connection strength and reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com