In-tube auto-cleaning antiscale falling-film evaporation device

An evaporation device and automatic cleaning technology, applied in evaporation, evaporator accessories, separation methods, etc., to achieve the effects of easy operation, reliable operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

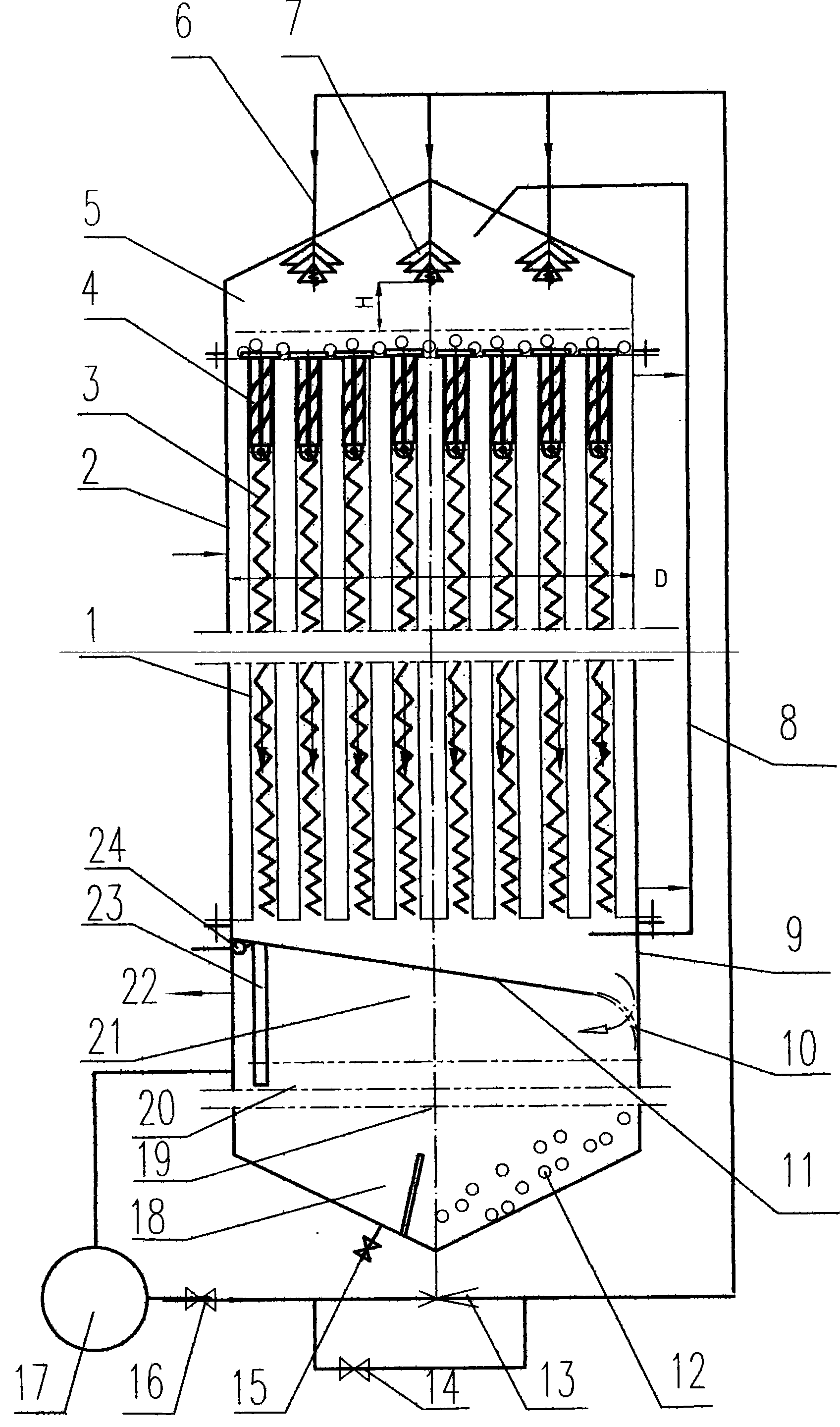

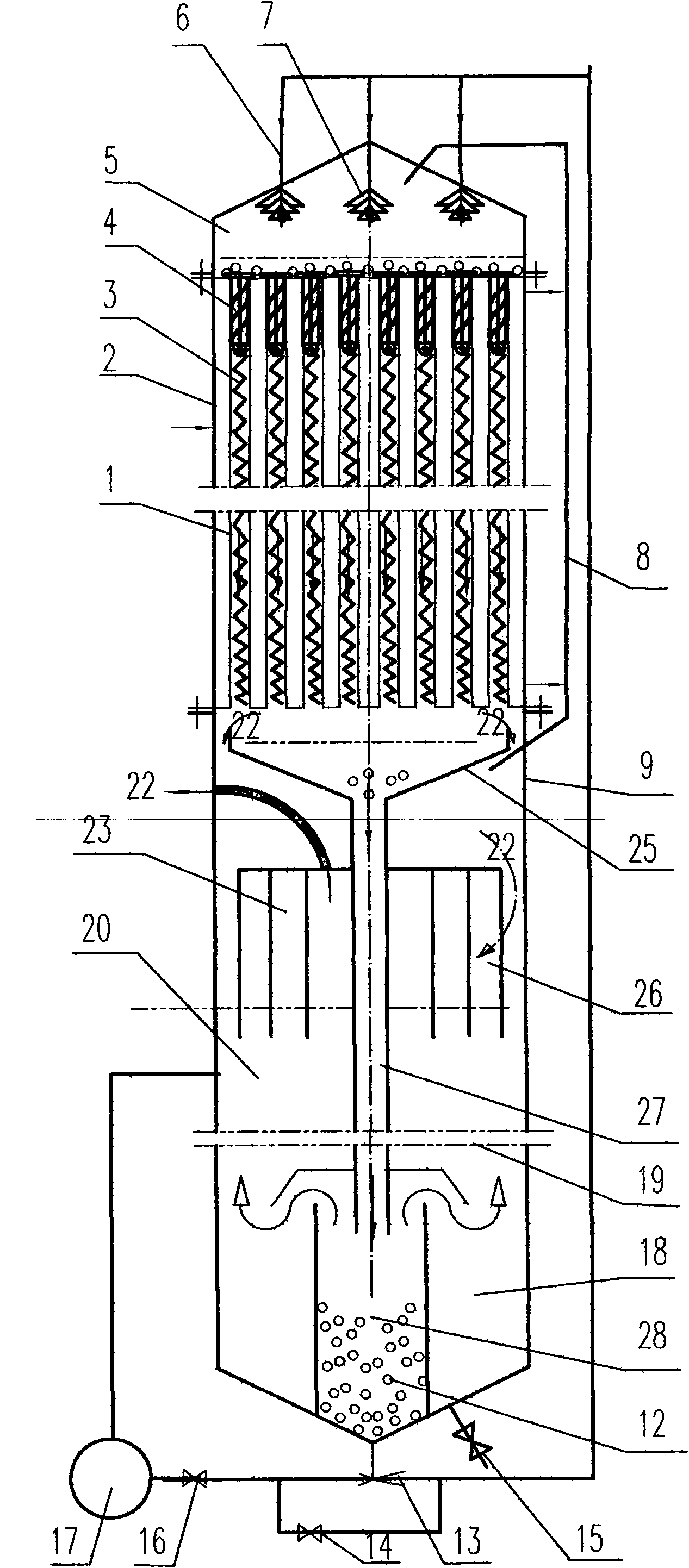

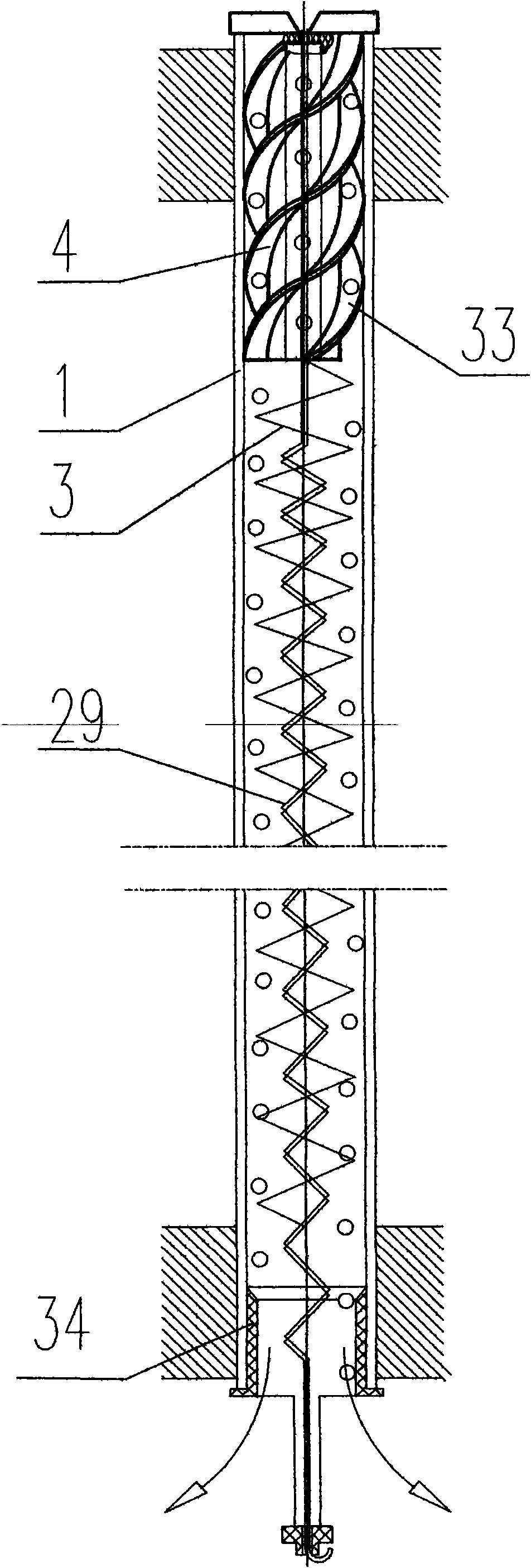

[0018] Attached below figure 1 , figure 2 , Figure 3a , Figure 3b , the present invention is described in further detail.

[0019] In the figure, 1 heating pipe 2 heating chamber 3 liquid film spiral 4 evenly distributed film forming spiral 5 upper pipe box 6 spray pipe 7 spray head 8 connecting pipe 9 lower pipe box 10 water curtain 11 oblique deflector 12 flow Chemical ball 13 Venturi 14 Bypass valve 15 Slurry discharge valve 16 Outlet valve 17 Circulation pump 18 Coarse crystal zone 19 Circulation tank 20 Fine crystal zone 21 Liquid foam separation chamber 22 Secondary steam pipe 23 Demister 24 Flushing pipe 25 Liquid contact Disk 26 spiral channel centrifugal demister 27 central flow channel 28 ball collecting chamber 29 steam spiral 30 support rib 31 central tube inner hole 32 central tube 33 spiral piece 34 fixed frame

[0020] An automatic cleaning and anti-scaling falling film evaporation device in the tube, the main components are the upper tube box 5, the flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com