Method for testing content of hydrogen cyanide in gas

A method of determination, hydrogen cyanide technology, applied in the field of coal coking analysis and testing, can solve the problems of waste liquid pollution, toxic and harmful reagents, time-consuming, etc., and achieve the effect of accurate determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

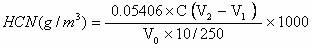

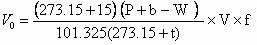

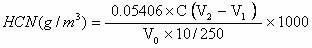

[0031] (1) In two bottles filled with potassium hydroxide solution with a mass concentration of 30% and a volume of 50mL, feed gas in sequence up to the gas sampling volume , and combine two bottles of absorption liquid to obtain 100mL of sample absorption liquid that absorbs hydrogen cyanide; among them, the gas sampling volume Calculated by the following formula:

[0032]

[0033] gas sampling volume It is measured by a conventional wet gas flowmeter, the specific value is 110L (behind the tower), and the correction coefficient of the wet gas flowmeter 0.91, the average temperature of the gas when sampling Atmospheric pressure at 11.0°C when sampling 81.22KPa, the gas pressure at the time of sampling is 0 KPa, and the saturated water vapor pressure W at t℃ is 1.303 KPa, the calculated For 80.05L:

[0034] (2) Dilute the sample absorption solution obtained in step (1) to 250mL with water, shake well to obtain the sample dilution, take 10.00mL of the sample di...

Embodiment 2

[0045] (1) In two bottles filled with potassium hydroxide solution with a mass concentration of 35% and a volume of 60mL, feed gas in sequence up to the gas sampling volume , combine two bottles of absorption liquid to obtain the sample absorption liquid that absorbs hydrogen cyanide; among them, the gas sampling volume Calculated by the following formula:

[0046]

[0047] gas sampling volume It is measured by a conventional wet gas flowmeter, the specific value is 100L (behind the tower), and the correction coefficient of the wet gas flowmeter 0.91, the average temperature of the gas when sampling Atmospheric pressure at 6°C when sampling 81.53 KPa, the gas pressure at the time of sampling The saturated water vapor pressure W at 0 KPa and t°C is 0.935 KPa, calculated For 74.73 L:

[0048] (2) Dilute the sample absorption solution obtained in step (1) to 250mL with water, shake well to obtain the sample dilution, take 10.00mL of the sample dilution, and add cad...

Embodiment 3

[0059] (1) In two bottles filled with potassium hydroxide solution with a mass concentration of 40% and a volume of 55mL, feed gas up to the gas sampling volume , must absorb the sample absorbing liquid containing hydrogen cyanide; among them, the gas sampling volume Calculated by the following formula:

[0060]

[0061] Among them, the gas sampling volume It is measured by a conventional wet gas flowmeter, and the specific value is 60L (in front of the tower), the correction coefficient of the wet gas flowmeter 0.92, the average temperature of the gas when sampling Atmospheric pressure at 10°C when sampling The gas pressure at the time of sampling is 81.20 KPa The saturated water vapor pressure W at 0 KPa and t°C is 1.228 KPa, calculated For 44.34L:

[0062] (2) Dilute the sample absorption solution obtained in step (1) to 250mL with water, shake well to obtain the sample dilution, take 10.00mL of the sample dilution, and add cadmium acetate solution dropwise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com