Back plate and backlight module using same

A backlight module and backplane technology, which is applied in the field of backlight modules, can solve the problems that the heat of aluminum extrusion cannot be quickly transferred and the temperature of the backlight module is high, and achieve the effects of reducing material costs, reducing processing technology, and improving heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

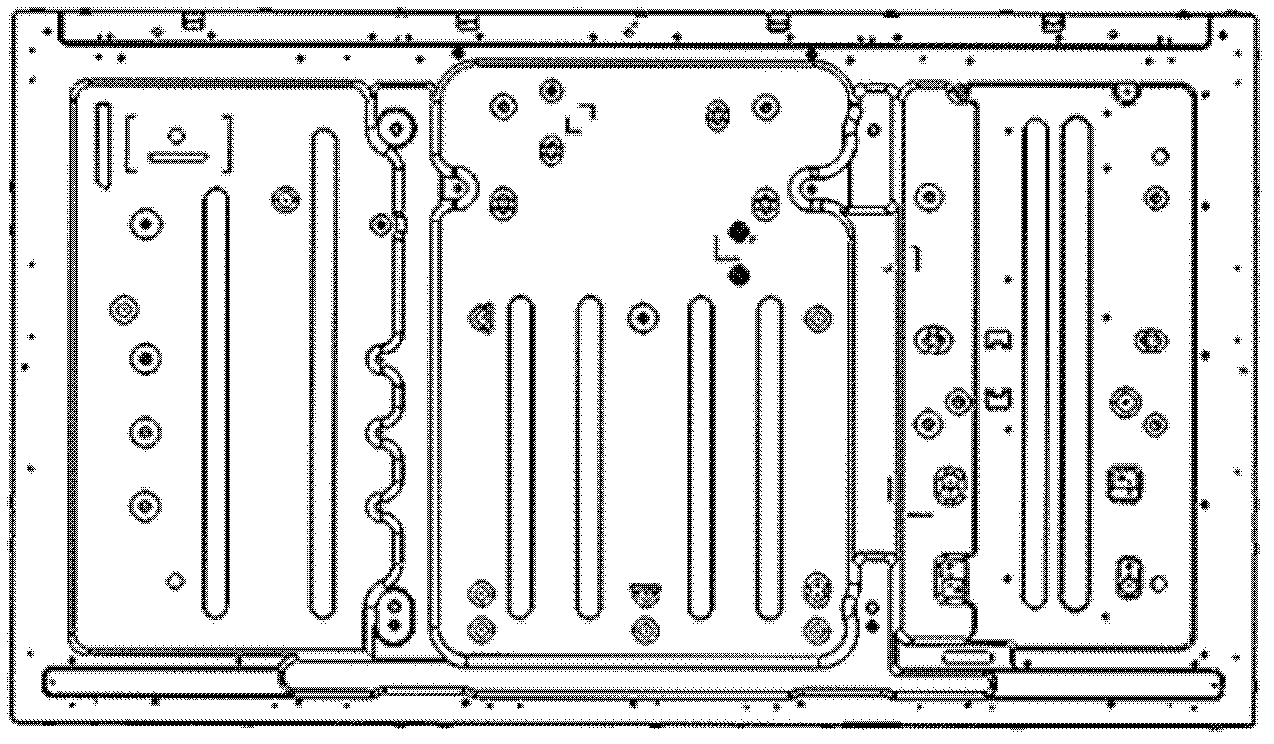

[0022] The present invention further illustrates the present invention by taking a low-cost frame-type backplane as an example. Of course, the present invention is also applicable to integrally formed backplanes, that is, suitable for such as figure 1 backplane shown.

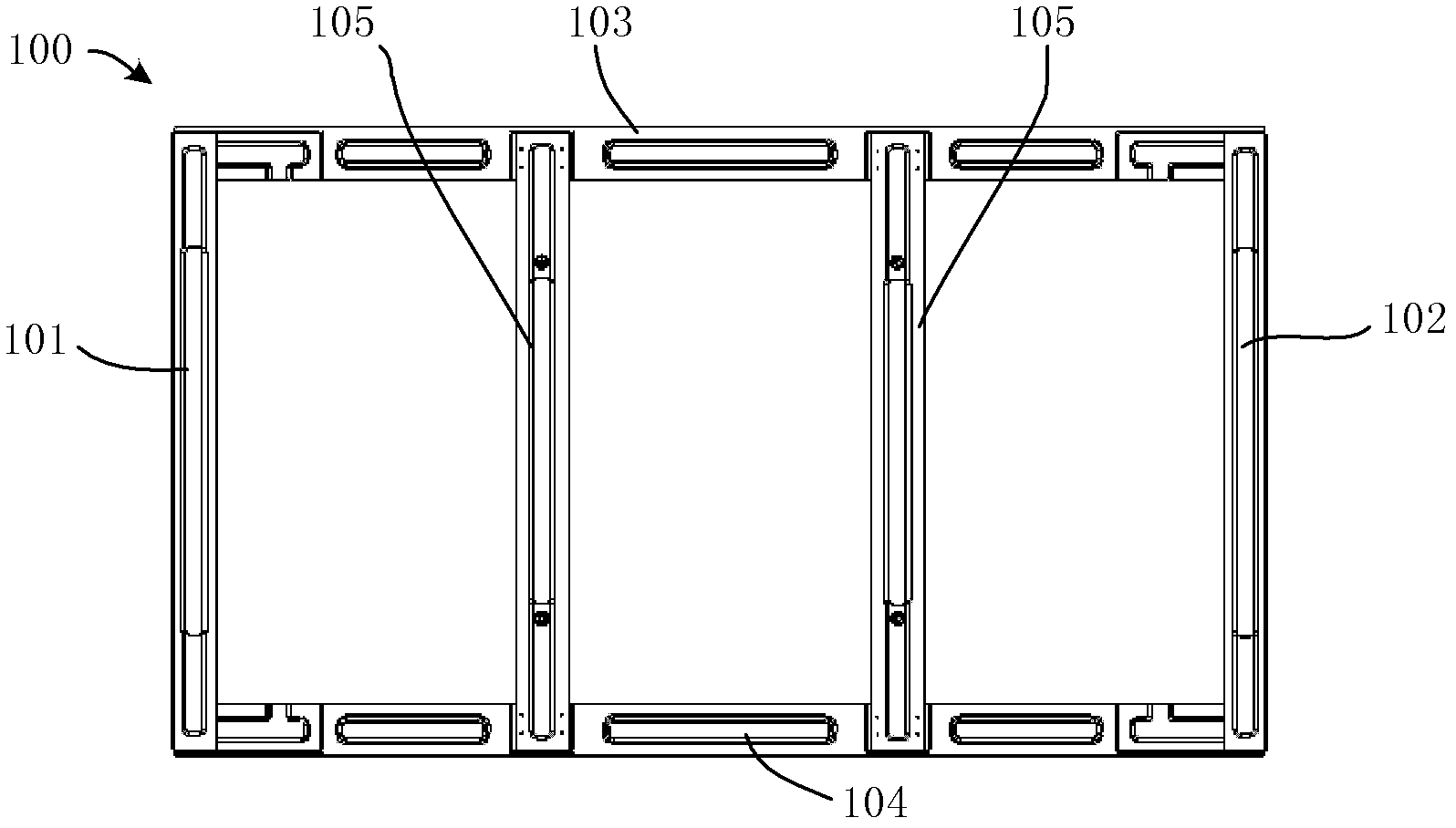

[0023] Such as figure 2 Shown is an embodiment of the present invention, the framed backplane 100 includes: a left side bracket 101, a right side bracket 102, an upper side bracket 103, a lower side bracket 104 and a middle bracket 105, wherein the left side bracket 102 is the light incident side The bracket is used to fix the light source of the backlight module.

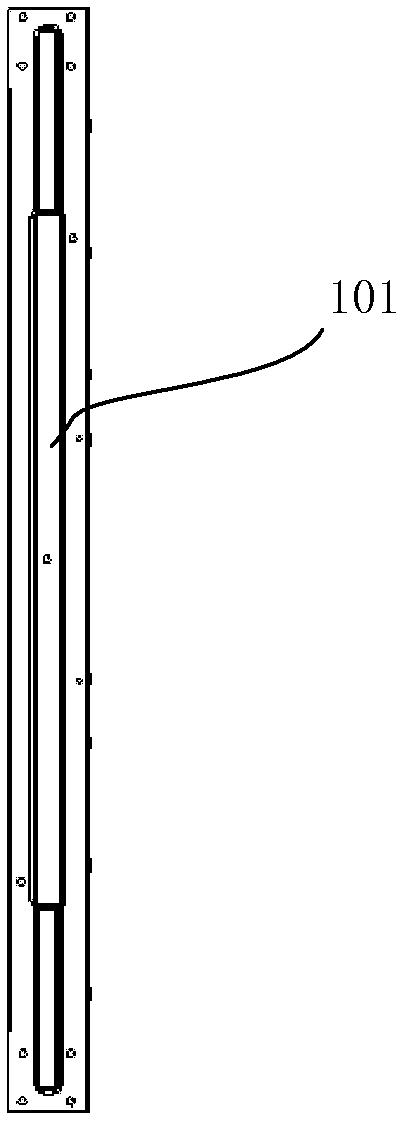

[0024] Such as image 3 and Figure 4 Shown is the left frame 101 of the frame-type backplane 100. As shown in FIG. The opposite inner surface of the wall 1011 is coated with a heat dissipation material coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com