Active gate bottom-edge device with function of adjusting water column pressure

A water column pressure, active technology, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve the problems of large opening and closing force and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

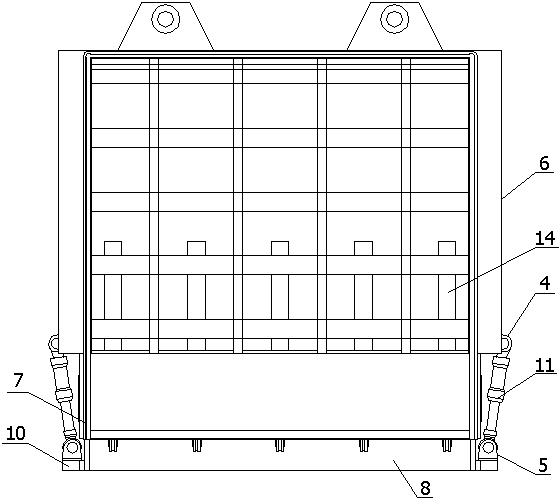

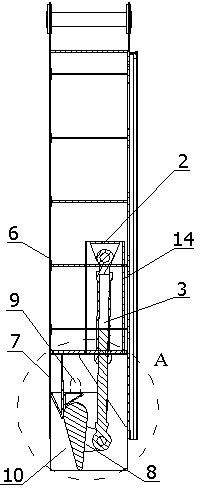

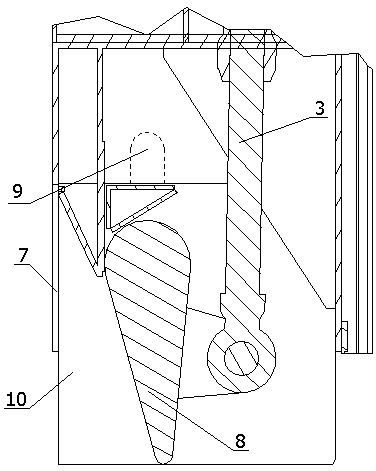

[0031] Such as figure 1 , 2 , 3, a device for actively adjusting the bottom edge of the water column pressure gate, including a rotating support 2, a rotating power mechanism 3, a first ear seat 4, a second ear seat 5, a door leaf 6, a bottom edge frame 7, a bottom Edge mechanism, slideway 9, bottom edge bracket 10 and vertical power mechanism 11, the bottom edge mechanism in this implementation is the bottom edge rotating mechanism 8, and described rotating support 2 is fixedly installed on the door leaf 6, and the rotating power mechanism 3. One end is hinged on the rotating support 2, and the other end of the rotating power mechanism 3 is hinged on the rotating side of the bottom edge rotating mechanism 8. The bottom edge frame 7 is fixedly installed on the bottom of the door leaf 6, and the bottom edge frame 7 is provided with a slide Road 9; the bottom edge bracket 10 is L-shaped, the side of the bottom edge bracket 10 is arranged between the bottom edge frame 7 and the ...

Embodiment 2

[0036] Such as Figure 4 , 5 , shown in 6 and 7, a kind of active adjustment water column pressure gate bottom edge device, comprises rotating support 2, rotating power mechanism 3, door leaf 6, bottom edge frame 7, bottom edge mechanism and vertical power mechanism 11, this The bottom edge mechanism in the embodiment is the bottom edge rotating mechanism 8, the rotating support 2 is fixedly installed on the door leaf 6, one end of the rotating power mechanism 3 is hinged on the rotating support 2, and the other end of the rotating power mechanism 3 is hinged on the bottom edge. On the rotating side of the edge turning mechanism 8, the bottom edge frame 7 is fixedly installed on the bottom of the door leaf 6, and the bottom edge frame 7 is provided with a shaft hole 12, and the fixed side of the bottom edge turning mechanism 8 passes through the shaft hole 12 through a hinge shaft. Hinged on the bottom edge frame 7; in this embodiment, the rotating power mechanism 3 is an oil...

Embodiment 3

[0039] Such as Figure 4 , 5 , 8 and 9, a device for actively adjusting the bottom edge of the water column pressure gate, including a rotating support 2, a rotating power mechanism 3, a door leaf 6, a bottom edge frame 7, a bottom edge mechanism and an elastic mechanism 13, the present embodiment The bottom edge mechanism is the bottom edge rotating mechanism 8, the rotating support 2 is fixedly installed on the door leaf 6, one end of the rotating power mechanism 3 is hinged on the rotating support 2, and the other end of the rotating power mechanism 3 is hinged on the bottom edge to rotate On the rotating side of the mechanism 8, the bottom edge frame 7 is fixedly installed on the bottom of the door leaf 6, and the bottom edge frame 7 is provided with a shaft hole 12, and the fixed side of the bottom edge rotating mechanism 8 is hinged through the shaft hole 12 through the hinge shaft. On the bottom edge frame 7; in the present embodiment, the rotating power mechanism 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com