Air guide brick and air guide wall thereof as well as pulverized coal destructive distillation carbonization chamber applying brick and wall

A technology of gas-conducting bricks and gas bricks, which is applied in the direction of special carbonization, indirect heating carbonization, carbonization gas discharge device, etc., which can solve the problems of long journey of pyrolysis gaseous products, long residence time of gaseous products, low yield of liquid products, etc. problem, to achieve the effect of reducing residence time, easy promotion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

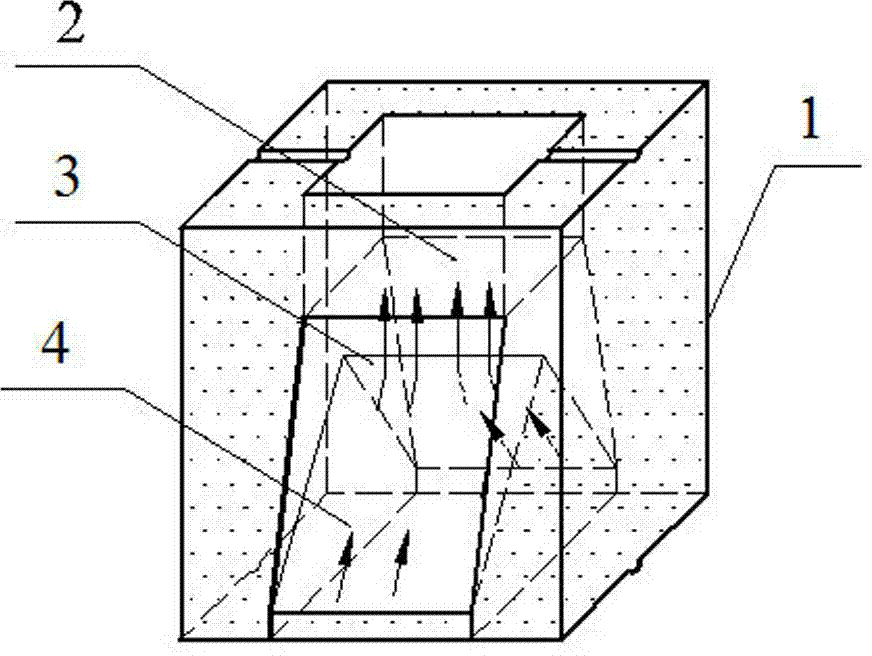

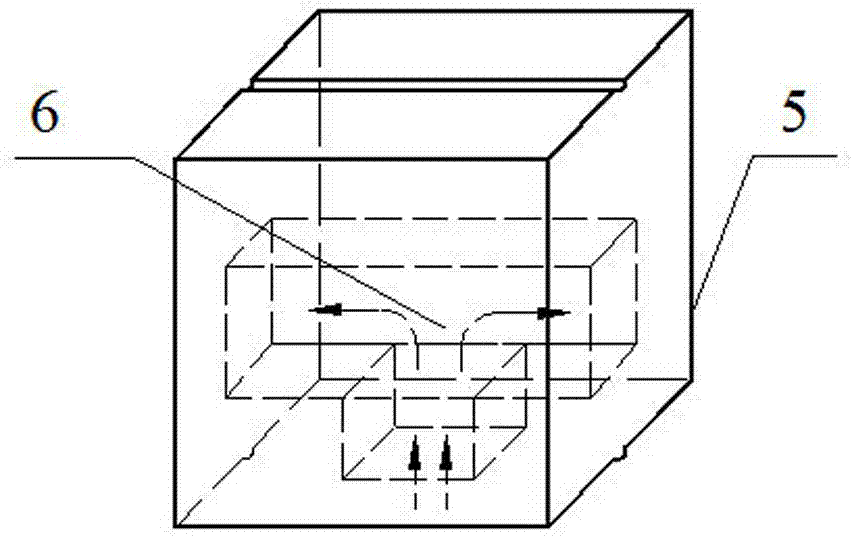

[0025] as attached figure 1 , figure 2 , image 3 and Figure 4 As mentioned above, the gas-conducting brick 13 provided by the present invention is to open the gas-absorbing brick 1 and the exhaust brick 5 with a gas channel structure in the gas-conducting brick 13, and its structural shape is a rectangular parallelepiped or a cube. In the present invention, the thermal conductivity of the designed air-conducting brick 13 is at least less than 4.78 W / (m·℃), and its material is mainly composed of silicon oxide, such as silica brick and clay brick. The brick 13 weakens the heat transfer from the outside to the inside of the air-conducting brick 13, that is, there is a large temperature difference between the inside and outside of the wall, which avoids secondary cracking of part of the gas in the wall.

[0026] The air-absorbing brick 1 designed by the present invention is provided with a gas passage of a "human" structure 3 inside, and the gas passage of the "human" struct...

Embodiment 2

[0030] On the basis of Example 1, implement a kind of air-conducting wall 12 using air-conducting bricks according to the present invention, as attached Figure 5 and Figure 6 Said, including gas-receiving brick 1, exhaust brick 5 and standard brick 14. The present invention adopts the air-conducting wall 12 stacked with the air-receiving brick 1 and the exhaust brick 5 of the "human" structure as basic structural units, and adopts the third combination scheme in Embodiment 1. Wherein, the method of stacking the wall includes horizontal masonry and vertical masonry, and both the horizontal masonry and the vertical masonry are implemented sequentially or crosswise.

[0031] as attached Figure 5 As mentioned above, in the masonry method of the air guide wall 12 (1) designed in the present invention, the "human" type air receiving brick 1 and the exhaust brick 5 used have the same height and width, but different lengths. slightly longer. When laying horizontally, the "human...

Embodiment 3

[0035] as attached Figure 5 And attached Figure 7 As described above, on the basis of Examples 1 and 2, a pulverized coal carbonization and carbonization chamber provided by the present invention is implemented, including the above-mentioned gas-guiding wall 12 with the gas-guiding structure and the supporting wall 17 provided. The gas guide wall 12 designed by the present invention is arranged on the center line of the carbonization chamber 16, and is parallel to the combustion chamber 18 on both sides, and the carbonization chamber 16 is divided into two, and the pulverized coal is carbonized by carbonization. The particle size is less than 10mm. The air-guiding wall 12 is built by combining air-absorbing bricks 1 and exhaust bricks 5 with "T"-shaped structures 6 and "-"-shaped structures 7 as basic structural units. When laying horizontally, the basic structural unit and the standard brick 14 are arranged flatly at intervals. Inside the gas guide wall 12, there are uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com