Pilot type control valve

A control valve and pilot-operated technology, applied in the mechanical field, can solve the problems that the control valve cannot be applied, and achieve the effects of easy implementation, reduced opening torque, and smooth valve opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

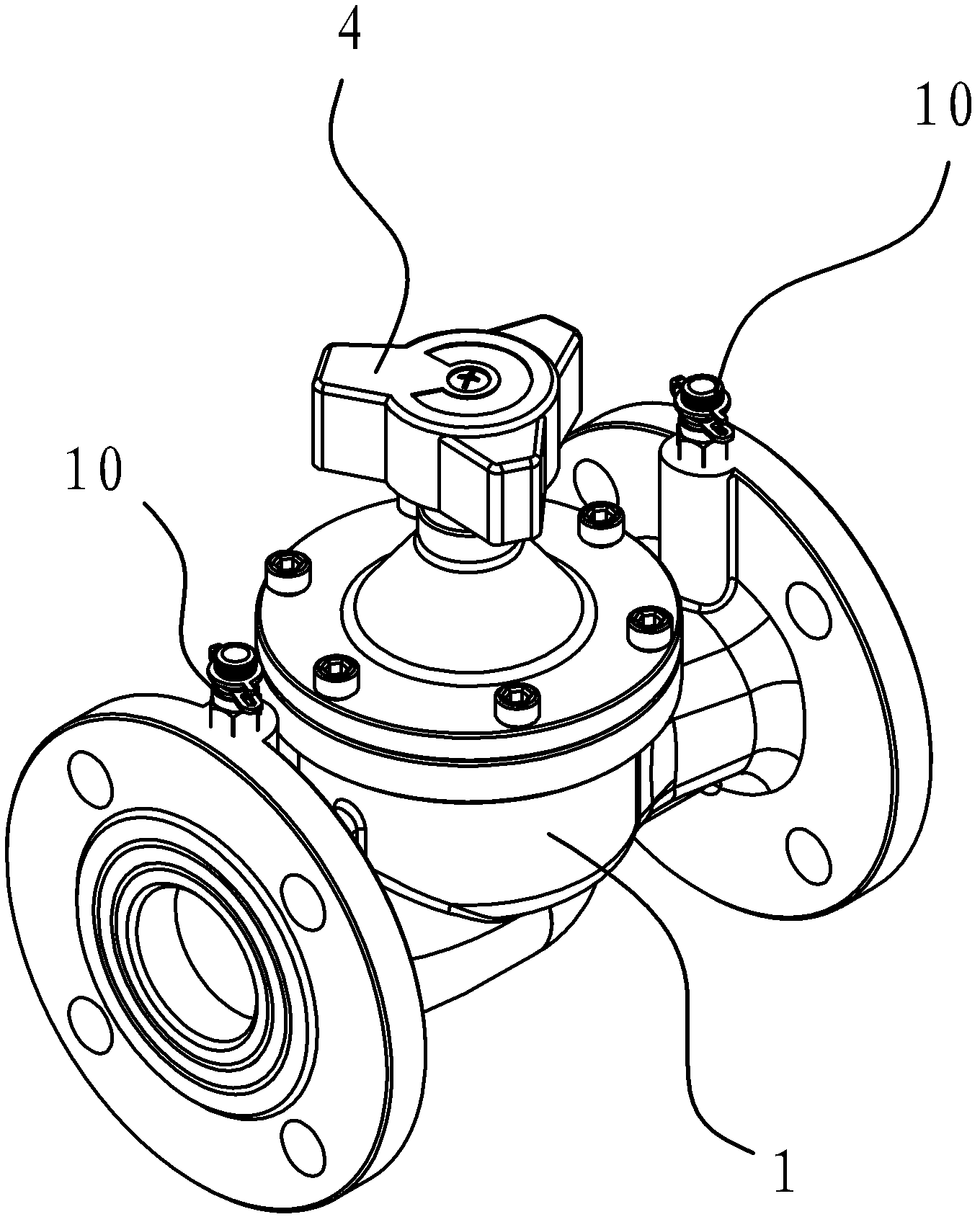

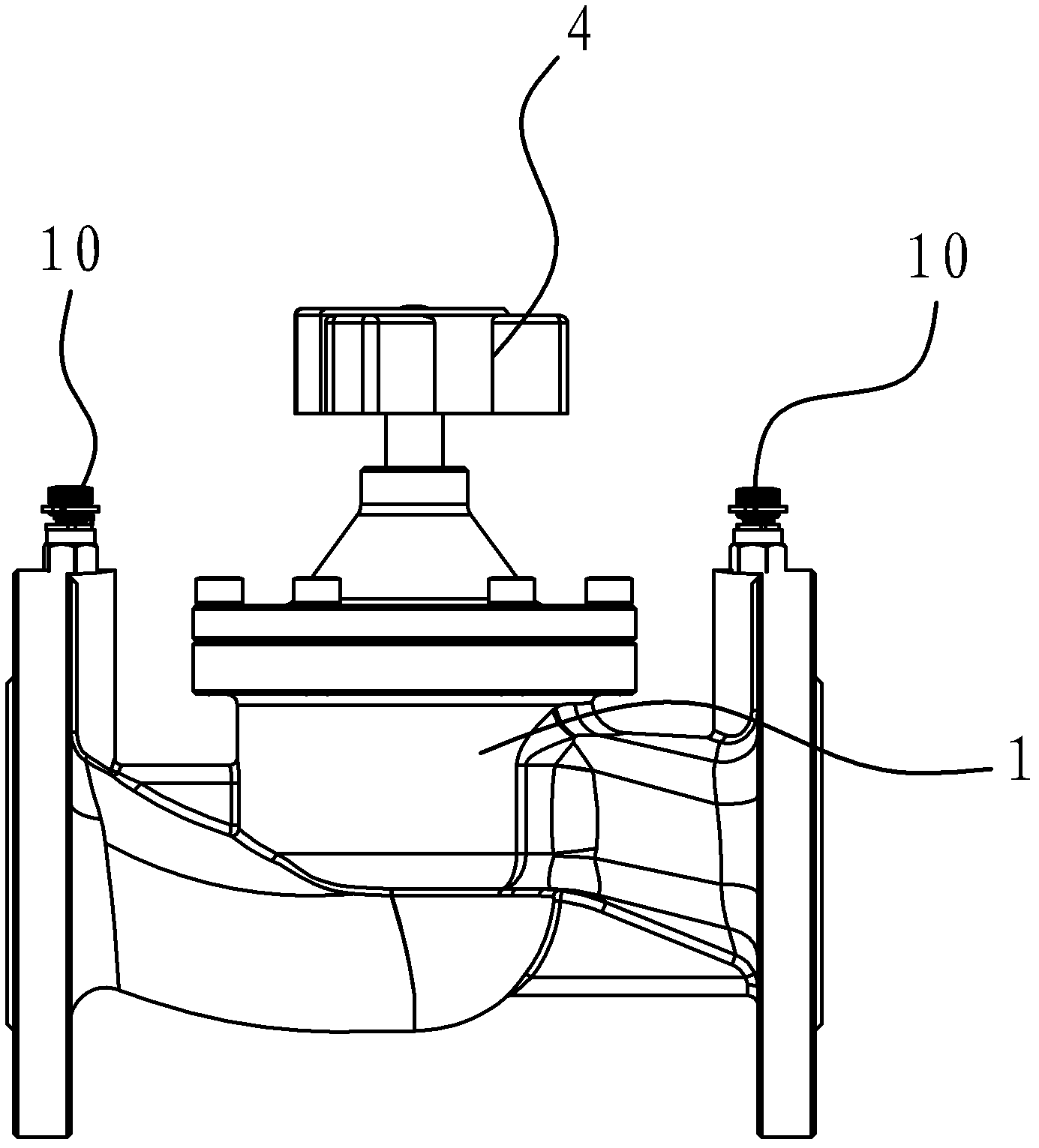

[0034] Such as figure 1 and figure 2 As shown, the pilot control valve includes a valve body 1 , a valve core 2 , a valve stem 3 and a handle 4 . The valve core 2 is located in the valve body 1, the inner end of the valve rod 3 is connected with the valve core 2, and the outer end of the valve rod 3 protrudes from the valve body 1 and is connected with the handle 4.

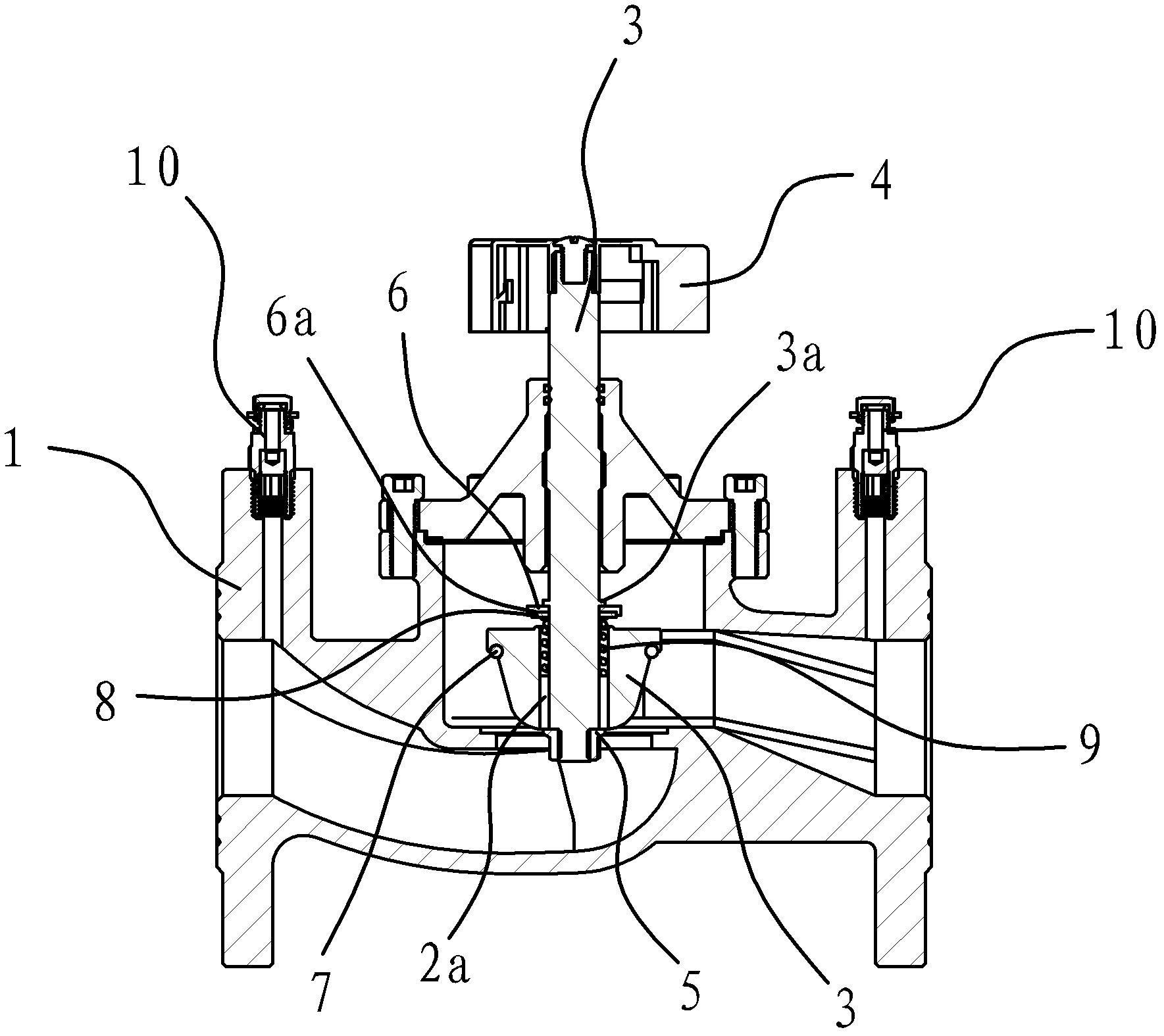

[0035] Such as image 3 and Figure 4 As shown, the spool 2 is cylindrical and sleeved on the valve stem 3. The valve stem 3 has a nut 5 that can abut on the bottom port of the spool 2 and a small spool that can abut on the top port of the spool 2. 6. In this embodiment, a large sealing ring 7 is sheathed on the outer side of the valve core 2 .

[0036] The spool 2 is located between the nut 5 and the small spool 6 and it can move between the two. There is a channel for the fluid medium to pass between the spool 2 and the valve stem 3. The small spool 6 and the top of the spool 2 There is a sealing structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com