Clutch mechanism for single drive system of washing machine

A clutch mechanism, single-drive technology, applied in other washing machines, applications, washing devices, etc., can solve the problems of erosion of impurities, short service life, noise and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

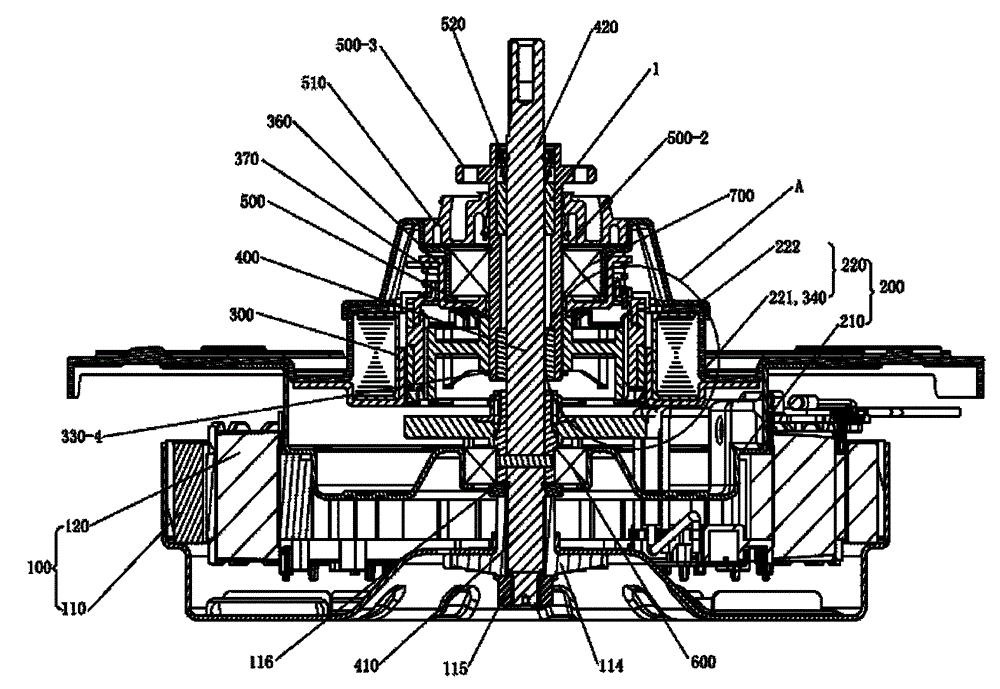

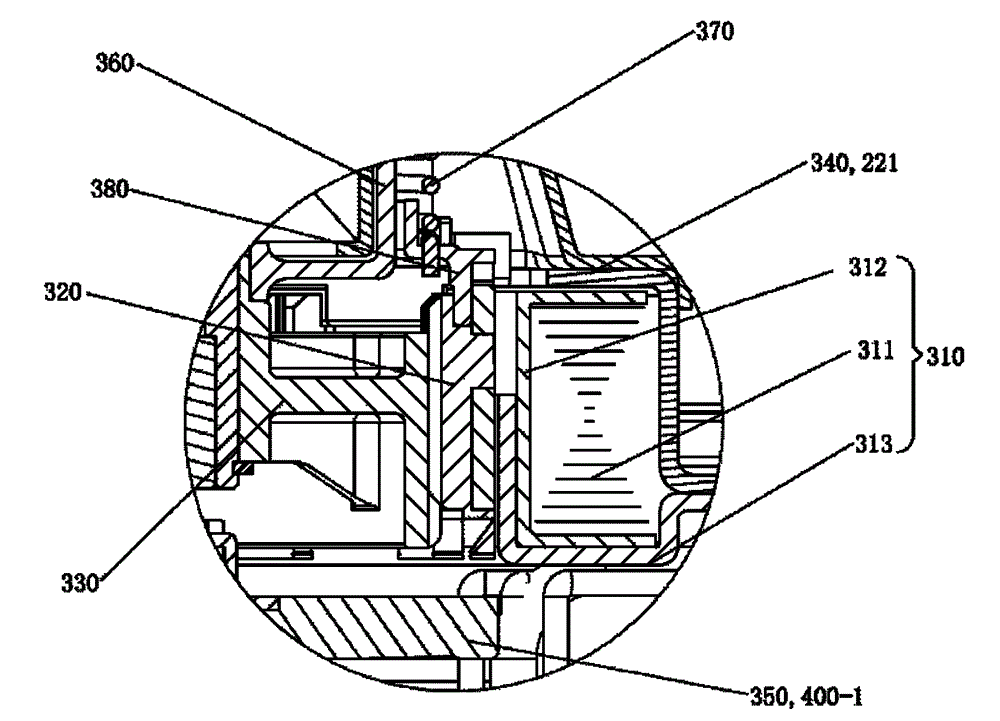

[0105] Embodiment 1, as Figure 1-5 , Figure 11 As shown, combined with other related drawings, a single drive system of a washing machine includes a motor 100, a housing 200, a clutch mechanism 300, a drive shaft 400, and a drive sleeve 500. There are two oil bearings 1 to realize that the drive shaft 400 is rotatably arranged in the drive shaft sleeve 500, the input end of the drive shaft 400 is connected with the motor 100, the output end of the drive shaft 400 is connected with the wave wheel or agitator of the washing machine, and the drive shaft sleeve 500 The output end is fixedly connected to the inner tub of the washing machine, and the clutch mechanism 300 is located inside the casing 200, wherein:

[0106] The drive shaft 400 includes a drive input shaft 410 and a drive output shaft 420, the drive input shaft 410 and the drive output shaft 420 are coaxial, that is, a single power direct drive system, which is applied to a single drive direct drive washing machine;...

Embodiment 2

[0110] Embodiment 2, as Figure 6 , Figure 7 , Figure 11 As shown, and in combination with other related drawings, a single drive system of a washing machine, wherein: the drive shaft 400 includes a drive input shaft 410 and a drive output shaft 420, and the drive input shaft 410 and the drive output shaft 420 are not coaxial, A reduction gear transmission mechanism 800a is arranged between the drive input shaft 410 and the drive output shaft 420, which is a single-power reduction drive system, which is applied to a single-drive reduction washing machine. The reduction gear transmission mechanism 800a includes a sun gear 810a, five The planetary gear 820a, the inner ring gear 830a, the planetary gear cage 840a, the inner ring gear 830a is used as the meshing part 330, the clutch ring gear 320 is meshed and socketed outside the inner ring gear 830a, and the clutch ring gear 320 can move up and down along the inner ring gear 830a Moving, the sun gear 810a is fixedly arranged...

Embodiment 3

[0111] Embodiment 3, as Figure 8-11 As shown, combined with other related drawings, a double drive system of a washing machine, which includes a motor 100, a housing 200, a clutch mechanism 300, a drive shaft 400, a drive sleeve 500, and the drive shaft 400 and the drive sleeve 500 Two oil-impregnated bearings 1 are arranged in between to realize that the drive shaft 400 is rotatably arranged in the drive shaft sleeve 500, the input end of the drive shaft 400 is connected with the motor 100, the output end of the drive shaft 400 is connected with the wave wheel or agitator of the washing machine, and the drive shaft The output end of the sleeve 500 is fixedly connected to the inner tub of the washing machine, and the clutch mechanism 300 is located inside the casing 200, wherein:

[0112] The drive shaft 400 includes a drive input shaft 410 and a drive output shaft 420, the drive input shaft 410 and the drive output shaft 420 are coaxial, and a double drive gear transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com