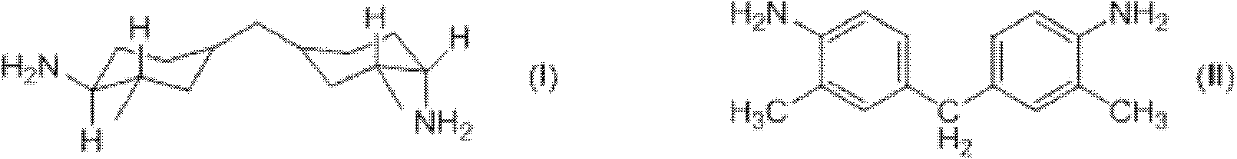

Method for synthesizing 3,3'-dimethyl-4,4'-diamino dicyclohexyl methane

A technology of diaminodicyclohexylmethane and diaminodiphenylmethane, applied in the field of synthesis of 3,MACM products, can solve problems such as turbidity or even crystallization, inconvenient production, storage, transportation and use, and affect the quality of downstream products, and achieve Low freezing point, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

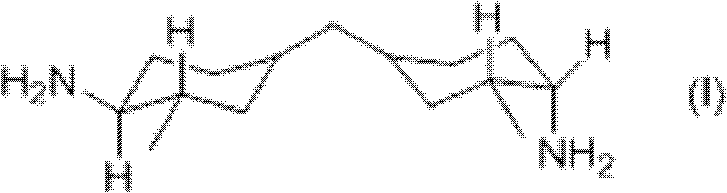

Method used

Image

Examples

Embodiment 1、3、5 and comparative example 1~2

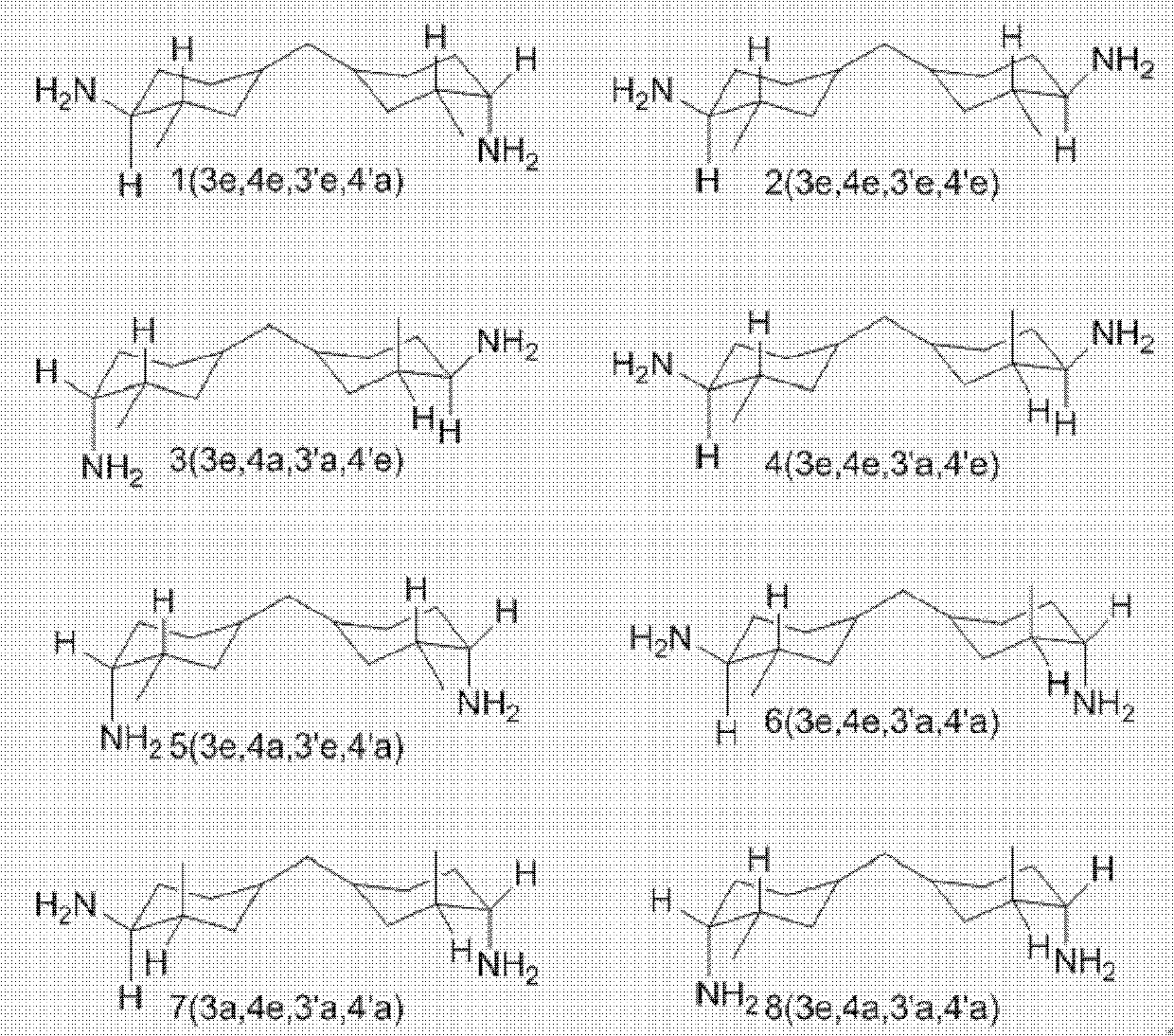

[0028] Put 200 grams of MDT, 280 grams of solvents as described in Table 2, 10 grams of catalyst, and add 1.60 grams of BaO into a 1L hydrogenation kettle. After feeding, replace with nitrogen three times, and then replace with hydrogen three times. Stirring was started, and after leak testing, the temperature was raised to 90°C and controlled at a temperature of 88-93°C and a pressure of 11.5MPa. The reaction was stirred for 10 hours to end hydrogen absorption, and the temperature was continued for 1.5 hours to obtain the MACM product. Wherein MACM-a refers to the MACM whose first isomer ratio is 20.1%; MACM-b refers to the MACM whose first isomer ratio is 32.6%.

Embodiment 2 and 4

[0030] Put 200 grams of MDT, 280 grams of solvents as described in Table 2, 10 grams of catalyst, and add 1.60 grams of BaO into a 1L hydrogenation kettle. After feeding, replace with nitrogen three times, and then replace with hydrogen three times. Stirring was started, and after the leak test, the temperature was raised to 55°C and controlled at a temperature of 53-58°C and a pressure of 14.5MPa. The reaction was stirred for 10 hours to end the hydrogen absorption, and the temperature was continued for 1.5 hours to obtain the MACM product. Wherein MACM-a refers to MACM with the ratio of the first isomer being 20.1%.

[0031] Table 2

[0032]

[0033] It can be seen from the corresponding examples 1 to 5 and comparative examples 1 to 2 data in table 2 that the first isomer ratio of the product obtained by catalytic MDT hydrogenation of different catalysts is different, wherein the ruthenium-rhodium bimetallic catalyst Ru-Rh / SiO 2 The resulting product had a low proportion...

Embodiment 6~8 and comparative example 3

[0035] Put 200 grams of MDT, 160 grams of MACM with a peak of 20.1% as a solvent, and 2.4 grams of Ru-Rh / SiO in a 1L hydrogenation kettle 2 Catalyst, and add 1.0 grams of alkali metal additives as shown in Table 3 or no additives, after feeding, replace with nitrogen three times, and then replace with hydrogen three times. Stirring was started, and after leak testing, the temperature was raised to 85°C, and the temperature was controlled between 83-88°C, and the pressure was 11.5MPa. The reaction was stirred for 10 hours to end the hydrogen absorption, and the temperature was continued for 1.5 hours to obtain the MACM product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com