Method for realizing on-site estimation on temperature of rotor magnetic steel of permanent magnet motor

A permanent magnet motor and rotor temperature technology, applied in radiation pyrometry, estimation/correction of motor parameters, instruments, etc., can solve problems such as demagnetization of permanent magnets, affecting the performance of permanent magnets, and not directly reflecting the actual temperature of the rotor. Achieve the effect of preventing demagnetization, improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

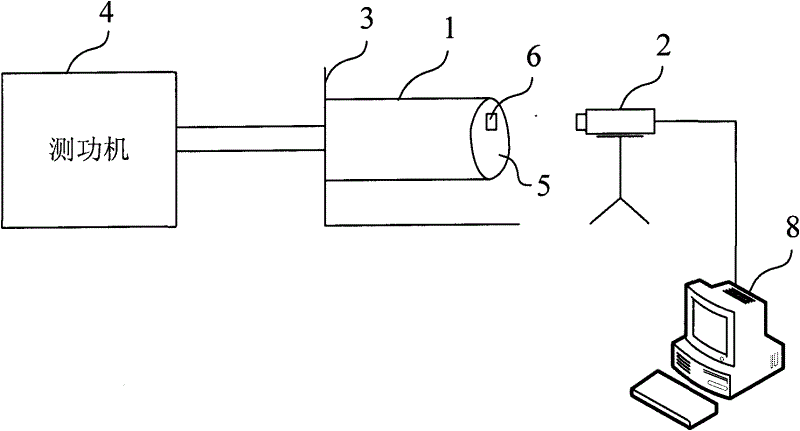

[0022] Such as figure 1 As shown, this figure schematically shows the basic composition of the temperature measurement system example for the rotor temperature and stator temperature test of the permanent magnet motor in the method of the present invention, which will be combined below figure 2 To describe in detail the components of the temperature measurement system.

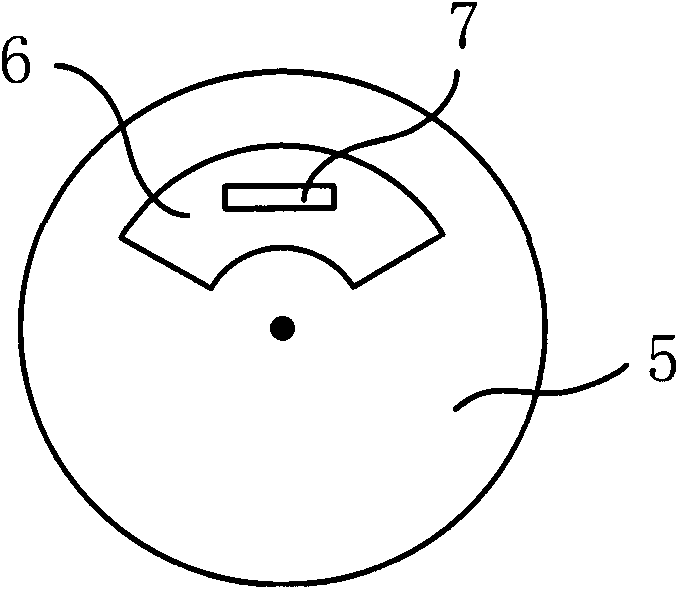

[0023] In the above example, the temperature measurement system includes a permanent magnet motor 1 , an infrared thermal imaging camera 2 , a dynamometer 4 coaxially connected with the permanent magnet motor 1 , a host computer 8 and at least one temperature sensor (not shown). Among them, such as figure 1 As shown, the permanent magnet motor 1 is provided with a motor controller and is fixed on the bracket 3, and a coating layer is provided on the end face of the rotor magnet 7 of the permanent magnet motor 1, and the coating layer is coated with the same paint. to form the same color. And, as shown in F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com