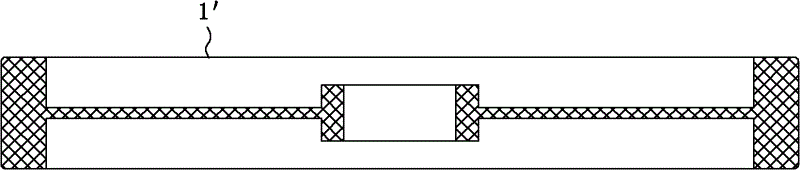

Stator disc of permanent magnet disc motor

A permanent magnet motor and stator technology, applied in electrical components, electromechanical devices, etc., can solve the problem that heat cannot be dissipated well, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

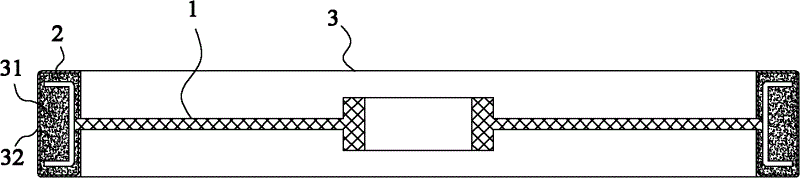

Embodiment 1

[0023] Embodiment 1: The box 3 in this embodiment is a metal box with good thermal conductivity, which has a metal box wall 32, and the box wall 32 is in contact with the heat-conducting insulating powder 31, and conducts heat to the outside at this time. Part is the box wall 32. In this embodiment, the heat of the exposed wires 2 on the outer ring of the stator disk can be quickly transferred to the box wall 32 through the heat-conducting insulating powder 31 and then transferred to the outside of the casing through the heat transfer mechanism connected with the box. The heat in the middle of the stator disk can also be quickly transferred to the wire 2 on the outer ring of the stator disk through the good thermal conductivity of the wire 2 in the middle of the stator disk, and then dissipated by the aforementioned method.

Embodiment 2

[0024] Embodiment 2: The box 3 in this embodiment is made of non-thermally conductive material. The box 3 is also provided with a metal sheet, metal plate or metal tube (not shown in the figure) that can conduct heat to the outside, and the metal sheet, metal plate or metal tube is in contact with the heat-conducting insulating powder 31 , At this time, the external conducting member is the metal sheet, metal plate or metal tube. The metal sheet, metal plate or metal tube can be close to the part of the wire 2 exposed outside the insulating matrix 1, but not in contact with the wire 2, so as to avoid wearing out the insulating paint on the outside of the wire 2 and causing damage to the wire 2. Short circuit accident. When a larger cooling capacity is required, heat can be quickly transferred to the outside by passing cooling liquid into the metal tube. In this embodiment, the heat of the exposed wires 2 on the outer ring of the stator disk can be quickly transferred to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com